Chemical Processing and Petrochemical Industries

Corrosion-Resistant Equipment

In the chemical processing industry, Nickel 201 sheet is extensively used to fabricate corrosion-resistant equipment. Its exceptional resistance to various corrosive substances, including caustic alkalis and organic acids, makes it an ideal material for manufacturing reaction vessels, storage tanks, and piping systems. The durability of Nickel 201 plate ensures prolonged equipment life, reducing maintenance costs and downtime in chemical plants.

Heat Exchangers and Condensers

Nickel 201 is highly favored for use in heat exchangers and condensers in petrochemical facilities due to its excellent thermal conductivity and resistance to high-temperature oxidation. Components made from Nickel 201 sheet are designed to efficiently transfer heat while maintaining structural integrity under challenging conditions. The material’s ability to withstand thermal cycling and resist scaling ensures long-lasting performance in demanding environments. By preventing degradation and preserving efficiency, Nickel 201 contributes to the reliability and effectiveness of heat transfer processes, making it a critical material for optimizing energy efficiency in petrochemical operations.

Catalyst Support Grids

In petrochemical refineries, Nickel 201 plate is commonly used to manufacture catalyst support grids. These grids are essential for holding catalysts in place during chemical reactions, ensuring optimal performance. The material’s strength and resistance to deformation at high temperatures make it ideal for maintaining the structural integrity of the grids. This ensures the catalyst remains evenly distributed throughout the reaction process, enhancing reaction efficiency and maximizing product yield. Nickel 201's durability in demanding conditions contributes to the overall effectiveness and reliability of chemical processing operations.

Aerospace and Defense Industries

Aircraft Engine Components

The aerospace industry relies on Nickel 201 sheet for manufacturing critical aircraft engine components. Its high strength-to-weight ratio and excellent resistance to oxidation at elevated temperatures make it suitable for producing combustion chambers, afterburner liners, and exhaust system parts. These components benefit from Nickel 201's ability to maintain structural integrity under extreme conditions, ensuring the safety and reliability of aircraft engines.

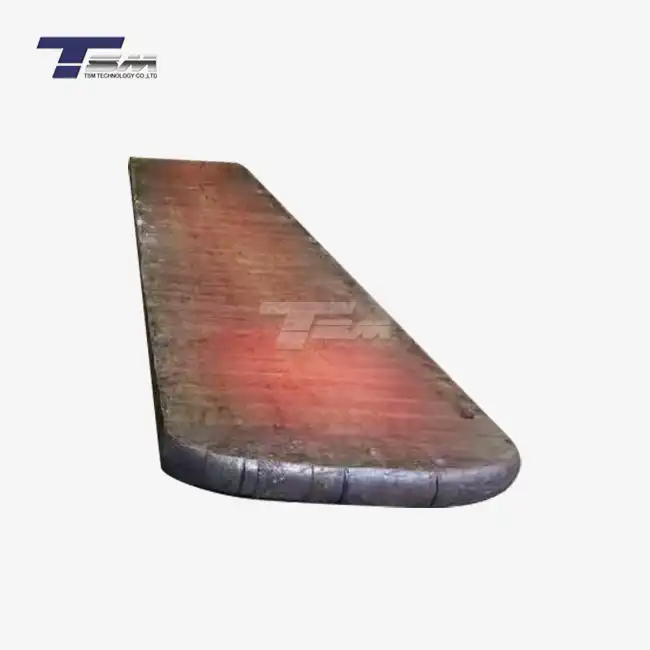

Missile and Rocket Systems

In defense applications, Nickel 201 plate finds use in missile and rocket systems. Its resistance to thermal shock and ability to withstand rapid temperature changes make it ideal for components exposed to high-speed airflow and combustion gases. Nickel 201 sheet is often employed in the fabrication of nozzles, thrust chambers, and propellant tanks, contributing to the overall performance and durability of these advanced weapon systems.

Satellite and Space Exploration Equipment

The space industry utilizes Nickel 201 in various applications, including satellite components and space exploration equipment. Its low magnetic permeability and stability in vacuum environments make it suitable for manufacturing structural elements, heat shields, and propulsion system parts. The material's resistance to atomic oxygen degradation in low Earth orbit further enhances its value in space applications.

Electronics and Energy Sectors

Vacuum Tubes and Electron Devices

Nickel 201 sheet plays a crucial role in the electronics industry, particularly in the production of vacuum tubes and electron devices. Its low gas content and excellent outgassing characteristics make it ideal for components that require high vacuum integrity. Nickel 201 plate is used to fabricate anodes, cathodes, and other internal parts of vacuum tubes, ensuring reliable performance in high-frequency applications and power amplification systems.

Fuel Cell Components

In the rapidly growing field of alternative energy, Nickel 201 finds application in fuel cell technology. Its corrosion resistance and ability to withstand high temperatures make it suitable for manufacturing bipolar plates and interconnects in solid oxide fuel cells. These components, made from Nickel 201 sheet, facilitate efficient electron flow and gas distribution within the fuel cell stack, contributing to overall system performance and longevity.

Nuclear Power Plant Equipment

The nuclear energy sector relies on Nickel 201 plate for various critical applications. Its resistance to radiation damage and excellent mechanical properties at elevated temperatures make it suitable for manufacturing reactor internals, heat exchanger tubes, and valve components. The material's low neutron absorption cross-section ensures minimal interference with nuclear reactions, while its corrosion resistance in high-temperature water and steam environments contributes to the safety and reliability of nuclear power plants.

Conclusion

Nickel 201 sheet has proven to be an indispensable material across various modern industries. Its unique combination of corrosion resistance, thermal stability, and mechanical strength makes it a versatile choice for applications ranging from chemical processing to aerospace engineering. As industries continue to push the boundaries of technology and performance, the demand for high-quality Nickel 201 plate is likely to grow. The material's ability to withstand extreme conditions while maintaining its properties ensures its continued relevance in driving innovation and progress across diverse sectors. As we look to the future, Nickel 201 will undoubtedly play a crucial role in shaping the next generation of industrial advancements and technological breakthroughs.

Contact Us

For more information about our high-quality Nickel 201 sheet and plate products, please don't hesitate to contact us at info@tsm-technology.com. Our team of experts is ready to assist you in finding the perfect solution for your industrial needs.