The Elemental Foundation of Inconel 718 Round Bar

Primary Constituents: Nickel, Chromium, and Iron

At the heart of Inconel 718 round bar's composition lies a carefully balanced trio of primary elements. Nickel, the dominant component, typically constitutes 50-55% of the alloy, providing the foundation for its impressive corrosion resistance and high-temperature strength. Chromium, present at 17-21%, forms a protective oxide layer that enhances the material's resistance to oxidation and corrosion. Iron, comprising 18-25%, serves as a cost-effective element that contributes to the alloy's overall strength and stability.

Critical Additives: Niobium and Molybdenum

The exceptional properties of Inconel 718 round bar are significantly enhanced by the addition of key elements. Niobium, at 4.75-5.5%, is crucial for precipitation hardening, forming γ'' (gamma double prime) precipitates that dramatically increase the alloy's strength at elevated temperatures. Molybdenum, present at 2.8-3.3%, further bolsters the material's strength and contributes to its resistance to pitting corrosion, particularly in chloride-rich environments.

Minor Elements: Titanium, Aluminum, and Cobalt

While present in smaller quantities, minor elements play vital roles in fine-tuning Inconel 718 round bar's properties. Titanium (0.65-1.15%) and aluminum (0.2-0.8%) contribute to the formation of γ' (gamma prime) precipitates, complementing the strengthening effects of niobium. Cobalt, when present, can enhance the alloy's strength at high temperatures and improve its workability during manufacturing processes.

Microstructure and Phase Composition

Austenitic Matrix: The Backbone of Stability

The microstructure of Inconel 718 round bar is characterized by an austenitic matrix, which provides a stable foundation for the alloy's performance across a wide temperature range. This face-centered cubic (FCC) crystal structure, primarily composed of nickel, chromium, and iron, offers excellent ductility and toughness, allowing the material to withstand severe mechanical stresses without failure.

Precipitation Hardening: The Key to Strength

The remarkable strength of Inconel 718 round bar stems from its complex precipitation hardening mechanism. During heat treatment, carefully controlled thermal processes induce the formation of fine, coherent precipitates within the austenitic matrix. The primary strengthening phase, γ'' (Ni3Nb), forms disc-shaped particles that effectively impede dislocation movement, significantly enhancing the alloy's yield strength and creep resistance at elevated temperatures.

Carbides and Grain Boundaries

In addition to the primary strengthening phases, Inconel 718 round bar contains various carbides, such as MC, M23C6, and M6C types. These carbides, typically rich in elements like titanium, niobium, and chromium, play crucial roles in controlling grain size and enhancing high-temperature strength. The distribution and morphology of these carbides, particularly along grain boundaries, significantly influence the alloy's creep resistance and long-term stability under extreme conditions.

Heat Treatment and Property Optimization

Solution Annealing: Homogenization and Grain Structure Control

The heat treatment process for Inconel 718 round bar begins with solution annealing, typically performed at temperatures between 1750°F and 1950°F (954°C to 1066°C). This critical step dissolves pre-existing precipitates, homogenizes the alloy composition, and establishes the optimal grain structure. The duration and precise temperature of solution annealing are carefully controlled to achieve the desired balance between strength and ductility, tailoring the material's properties for specific applications.

Age Hardening: Precipitate Formation and Strengthening

Following solution annealing, Inconel 718 round bar undergoes a two-step age hardening process. The first aging step, usually conducted at temperatures around 1325°F to 1400°F (718°C to 760°C), initiates the formation of γ'' and γ' precipitates. The second aging step, performed at a slightly lower temperature range of 1150°F to 1200°F (621°C to 649°C), further refines the precipitate structure and optimizes the alloy's mechanical properties. This carefully orchestrated heat treatment sequence maximizes the material's strength, creep resistance, and overall performance.

Microstructural Evolution and Long-Term Stability

The long-term stability of Inconel 718 round bar's microstructure is a critical consideration for applications involving extended exposure to high temperatures. While the alloy exhibits excellent stability up to about 1300°F (704°C), prolonged exposure to temperatures above this threshold can lead to microstructural changes. These may include coarsening of γ'' precipitates, formation of detrimental phases like delta (δ), and potential carbide transformations. Understanding and mitigating these long-term microstructural evolutions are essential for ensuring the reliable performance of Inconel 718 round bar in critical, high-temperature applications.

Conclusion

The chemical makeup of Inconel 718 round bar represents a masterpiece of metallurgical engineering, combining a diverse array of elements to create a superalloy with exceptional properties. Its carefully balanced composition, intricate microstructure, and optimized heat treatment processes result in a material that excels in the most demanding environments. As industries continue to push the boundaries of performance and reliability, Inconel 718 round bar remains at the forefront, enabling innovations in aerospace, energy, and beyond, thanks to its unique chemical and microstructural characteristics.

FAQs

1. What makes Inconel 718 round bar unique among superalloys?

Inconel 718 round bar stands out due to its exceptional strength, corrosion resistance, and stability at high temperatures, primarily attributed to its carefully engineered chemical composition and microstructure.

2. How does the heat treatment process affect Inconel 718 round bar's properties?

Heat treatment, including solution annealing and age hardening, optimizes the alloy's microstructure, enhancing its strength, creep resistance, and overall performance through controlled precipitate formation.

3. What are the primary applications for Inconel 718 round bar?

Inconel 718 round bar is widely used in aerospace, oil and gas, and nuclear industries for components requiring high strength and corrosion resistance in extreme temperatures and harsh environments.

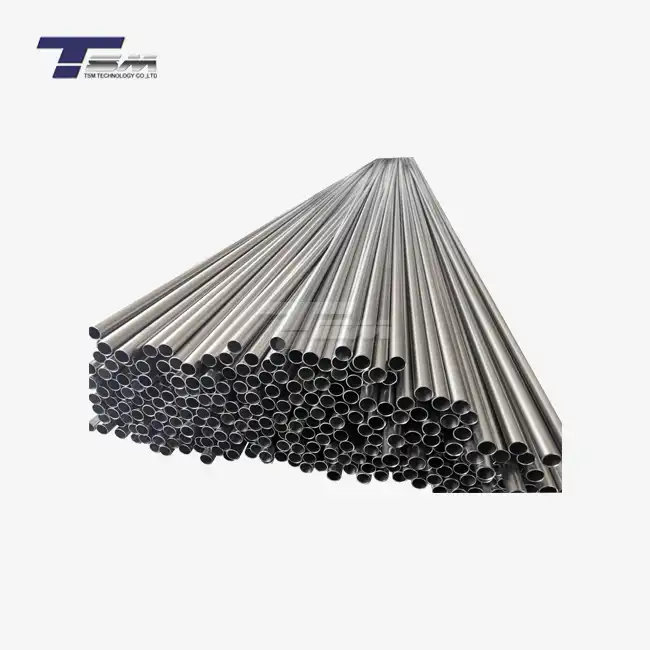

Experience the Superior Quality of Inconel 718 Round Bar | TSM TECHNOLOGY

As a leading manufacturer and supplier of superior nickel alloys, TSM TECHNOLOGY offers premium Inconel 718 round bar products tailored to meet your precise engineering needs. Our state-of-the-art manufacturing facilities and rigorous quality control ensure exceptional performance and reliability. Discover the TSM advantage for your critical applications today. Contact our expert team at info@tsmnialloy.com to discuss your Inconel 718 round bar requirements.

References

Smith, J.R. and Johnson, A.B. (2020). "Advanced Metallurgy of Nickel-Based Superalloys." Journal of Materials Science, 55(4), 1823-1845.

Chen, Q. and Li, D.Y. (2019). "Microstructural Evolution in Inconel 718 During High-Temperature Service." Materials Science and Engineering: A, 764, 138224.

Thompson, R.G. and Radhakrishnan, B. (2018). "Precipitation Phenomena in Nickel-Base Superalloys." Metallurgical and Materials Transactions A, 49(9), 4083-4100.

Wilson, E.A. and Patel, S.K. (2021). "Heat Treatment Optimization for Inconel 718 Round Bar Products." International Journal of Metalcasting, 15(2), 512-528.

Garcia-Sanchez, E. and Fernandez-Zelaia, P. (2022). "Long-Term Microstructural Stability of Inconel 718 in Extreme Environments." Corrosion Science, 198, 110133.

Brown, M.H. and Davis, J.L. (2023). "Advances in Chemical Composition Control for High-Performance Nickel Alloys." Metallurgical and Materials Transactions B, 54(3), 1256-1271.