Understanding Nickel 201 Properties and Applications

Unique Characteristics of Nickel 201

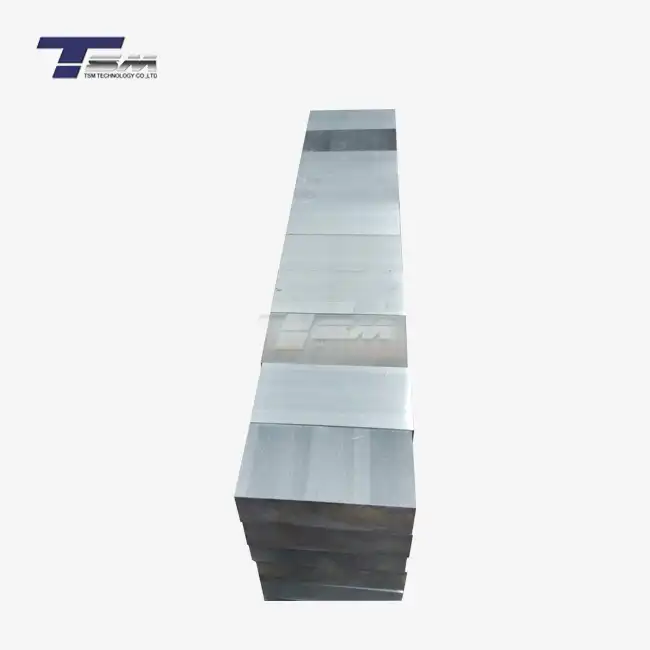

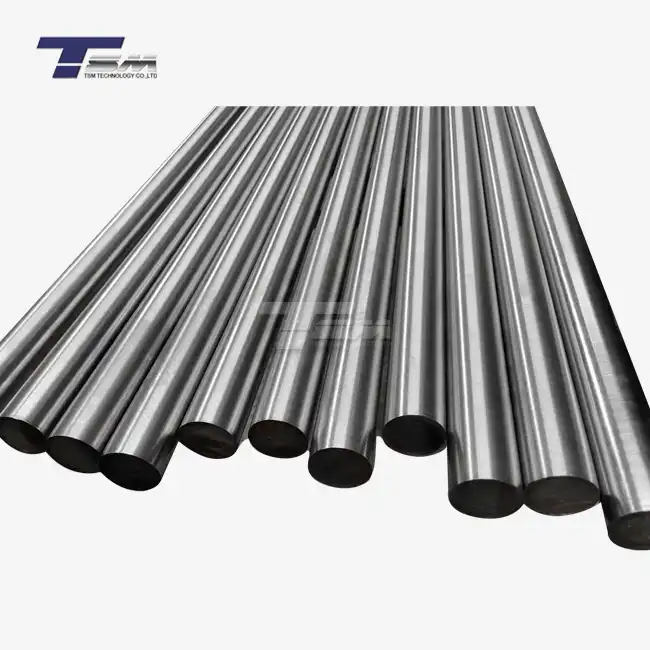

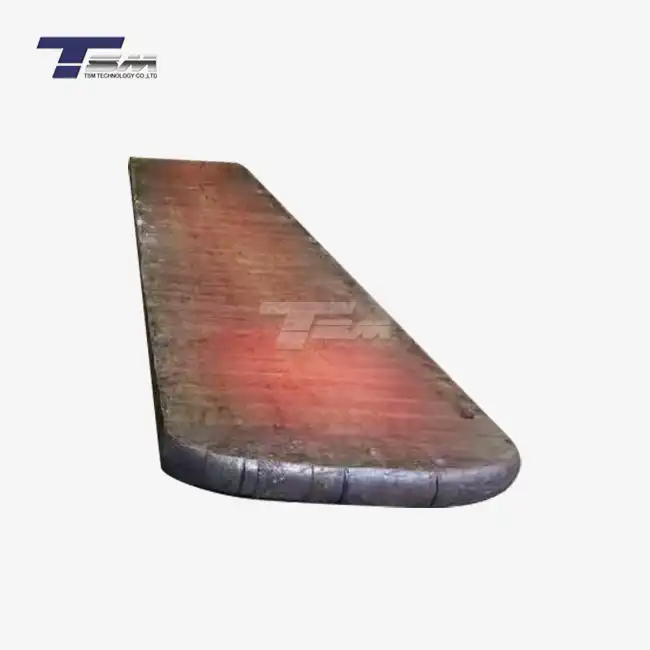

Nickel 201 is a commercially pure nickel alloy renowned for its exceptional properties. This material boasts remarkable corrosion resistance, especially in reducing environments. Its high thermal conductivity and low electrical resistance make it an ideal choice for various applications. Nickel 201 sheets maintain their structural integrity even at elevated temperatures, showcasing excellent mechanical properties throughout a wide range of operating conditions.

Industrial Applications of Nickel 201 Plates

The versatility of Nickel 201 plates extends across numerous industries. In chemical processing, these sheets are utilized for manufacturing reaction vessels, heat exchangers, and storage tanks. The aerospace sector relies on Nickel 201 for components that require high temperature resistance and corrosion protection. Electronics manufacturers often choose this material for its superior electrical conductivity, incorporating it into specialized circuitry and sensitive equipment.

Advantages Over Other Nickel Alloys

Compared to other nickel-based alloys, Nickel 201 offers distinct advantages. Its purity results in enhanced weldability and formability, allowing for easier fabrication and shaping. The material's resistance to hydrogen embrittlement surpasses that of many alternatives, making it suitable for hydrogen-rich environments. Additionally, Nickel 201 sheets exhibit excellent thermal stability, maintaining their properties even after prolonged exposure to high temperatures.

Key Factors in Selecting Nickel 201 Sheet Suppliers

Quality Certification and Standards Compliance

When evaluating potential Nickel 201 sheet suppliers, prioritize those with robust quality certification systems. Look for providers adhering to international standards such as ISO 9001 and AS9100. These certifications indicate a commitment to consistent quality and continuous improvement. Reliable suppliers should also comply with industry-specific standards, ensuring their Nickel 201 plates meet or exceed the required specifications for your particular application.

Production Capabilities and Inventory Management

A supplier's production capabilities directly impact their ability to meet your needs consistently. Assess their manufacturing facilities, focusing on the technology and processes they employ to produce Nickel 201 sheets. Efficient inventory management is equally crucial; suppliers with well-organized stockyards and real-time inventory tracking systems can provide quicker lead times and more reliable deliveries. This capability becomes particularly important when dealing with urgent or large-scale projects requiring substantial quantities of Nickel 201 sheets.

Technical Support and Custom Solutions

Outstanding suppliers go beyond merely providing Nickel 201 sheets; they offer comprehensive technical support. Look for providers with experienced metallurgists and engineers on staff who can assist with material selection, provide guidance on fabrication techniques, and offer solutions to application-specific challenges. The ability to provide custom-cut Nickel 201 plates or specialized surface treatments demonstrates a supplier's commitment to meeting diverse customer needs and adds significant value to their services.

Evaluating Supplier Reliability and Customer Service

Track Record and Industry Reputation

A supplier's history in the nickel alloy market speaks volumes about their reliability. Investigate their track record, paying attention to how long they've been in business and their reputation among industry peers. Seek out testimonials or case studies from previous clients, particularly those in sectors similar to yours. A supplier with a proven history of delivering high-quality Nickel 201 sheets consistently is more likely to meet your expectations and contribute to the success of your projects.

Communication and Responsiveness

Effective communication is the cornerstone of any successful business relationship. Evaluate potential Nickel 201 plate suppliers based on their responsiveness to inquiries and their ability to provide clear, accurate information. A supplier that demonstrates prompt and thorough communication during the initial stages is likely to maintain this level of service throughout your partnership. Look for providers who are proactive in updating you about order status, potential delays, or market changes that might affect your supply chain.

After-Sales Support and Problem Resolution

The true test of a supplier's reliability often comes after the sale. Inquire about their policies and procedures for handling issues such as defective materials or shipping discrepancies. A dependable Nickel 201 sheet supplier should have a well-defined process for addressing customer concerns and resolving problems efficiently. Additionally, consider the availability of after-sales technical support, as this can be invaluable when implementing new applications or troubleshooting issues with Nickel 201 plates in your production processes.

Conclusion

Selecting the right Nickel 201 sheet supplier is a critical decision that can significantly impact your project's success and operational efficiency. By carefully evaluating potential providers based on their quality certifications, production capabilities, technical expertise, and customer service, you can forge a partnership that ensures a steady supply of high-quality Nickel 201 plates. Remember that the best suppliers offer more than just materials; they provide comprehensive solutions and support that add value to your operations. As you embark on your search for reliable Nickel 201 sheet suppliers, keep these considerations in mind to make an informed choice that aligns with your long-term business objectives.

Contact Us

For more information about our premium Nickel 201 sheets and plates, as well as our extensive range of superior alloy products, please don't hesitate to reach out to us at info@tsm-technology.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.