Composition and Metallurgical Characteristics of Nickel 201

Chemical Makeup and Purity Levels

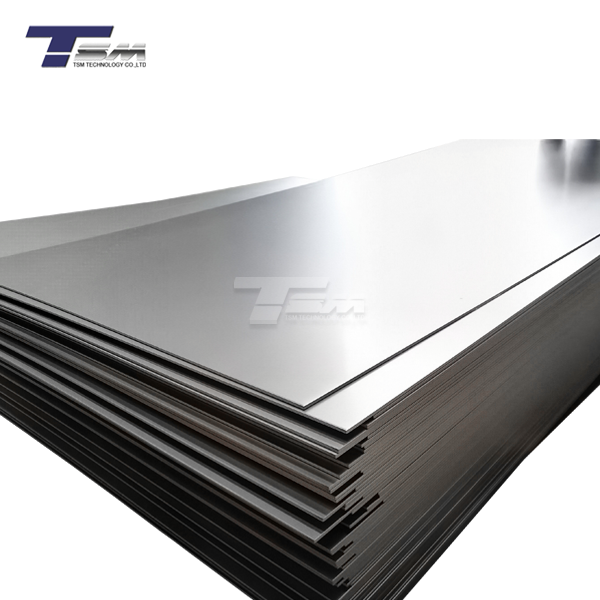

Nickel 201 is renowned for its high purity, typically containing over 99% nickel. This exceptional purity level contributes to its superior performance in various applications. The remaining composition usually includes trace amounts of elements such as carbon, manganese, iron, sulfur, and copper. These minimal additions play a crucial role in enhancing specific properties of the alloy without compromising its overall purity. The careful control of these trace elements during the manufacturing process ensures consistent quality and performance across different batches of Nickel 201 sheet and plate.

Crystalline Structure and Grain Orientation

The metallurgical characteristics of Nickel 201 are closely tied to its face-centered cubic (FCC) crystal structure. This structure imparts excellent ductility and formability to the material, allowing it to be easily shaped into complex geometries without compromising its integrity. The grain orientation in Nickel 201 sheet can be manipulated through controlled processing techniques, enabling manufacturers to optimize the material's properties for specific applications. Fine-grained structures can be achieved to enhance strength and toughness, while coarser grains may be preferred in certain high-temperature applications to improve creep resistance.

Alloying Effects on Material Properties

While Nickel 201 is primarily composed of pure nickel, the minimal alloying elements present can have significant effects on its properties. For instance, the small amount of carbon helps in strengthening the material through solid solution strengthening and carbide formation. Manganese aids in deoxidation during the melting process, improving the overall quality of the final product. The careful balance of these alloying elements ensures that Nickel 201 sheet maintains its desirable combination of strength, ductility, and corrosion resistance across a wide range of operating conditions.

Mechanical and Physical Properties of Nickel 201 Sheet

Strength and Ductility Characteristics

Nickel 201 sheet exhibits a remarkable balance of strength and ductility, making it an ideal choice for applications requiring both toughness and formability. Its yield strength typically ranges from 150 to 170 MPa, while its ultimate tensile strength can reach up to 450 MPa in the annealed condition. The material's elongation often exceeds 40%, showcasing its exceptional ductility. This combination of properties allows Nickel 201 plate to withstand significant deformation without fracturing, making it suitable for deep drawing and other forming operations. Additionally, the material's work hardening characteristics enable it to gain strength during cold working processes, further enhancing its versatility in manufacturing applications.

Thermal Conductivity and Expansion Behavior

One of the standout features of Nickel 201 is its excellent thermal conductivity, which is approximately 70 W/(m·K) at room temperature. This property makes it an excellent choice for heat transfer applications, particularly in heat exchangers and thermal management systems. The material's thermal expansion coefficient is relatively low, typically around 13.3 × 10^-6 m/(m·K) at 20-100°C. This low thermal expansion rate contributes to the dimensional stability of Nickel 201 sheet in applications involving temperature fluctuations, reducing thermal stresses and potential warping in complex assemblies.

Electrical and Magnetic Properties

Nickel 201 possesses unique electrical and magnetic properties that set it apart from other materials. Its electrical resistivity is approximately 0.096 μΩ·m at 20°C, making it a good electrical conductor. This property, combined with its corrosion resistance, makes Nickel 201 sheet an excellent choice for electrical contacts in harsh environments. Magnetically, Nickel 201 is ferromagnetic at room temperature, with a Curie point of about 354°C. Above this temperature, it becomes paramagnetic, a property that can be exploited in specific magnetic shielding or induction heating applications. The material's magnetic permeability can be tailored through heat treatment processes, allowing for customization to meet specific magnetic requirements in various industrial and scientific applications.

Corrosion Resistance and Chemical Compatibility of Nickel 201

Performance in Acidic and Alkaline Environments

Nickel 201 sheet demonstrates exceptional corrosion resistance across a wide spectrum of chemical environments. In acidic conditions, it exhibits remarkable resilience, particularly against reducing acids such as hydrochloric and sulfuric acid. This resistance stems from the formation of a stable, passive oxide layer on the surface, which acts as a barrier against further corrosion. In alkaline environments, Nickel 201 sheet maintains its integrity, showing minimal reactivity with caustic solutions. This broad-spectrum chemical compatibility makes it an ideal material for process equipment in industries dealing with aggressive chemicals, such as chemical processing plants and pharmaceutical manufacturing facilities.

Behavior in High-Temperature and Oxidizing Conditions

One of the distinguishing features of Nickel 201 is its ability to maintain its corrosion resistance at elevated temperatures. The material exhibits excellent oxidation resistance up to temperatures around 700°C, making it suitable for high-temperature applications in oxidizing atmospheres. This property is attributed to the formation of a dense, adherent oxide scale that protects the underlying metal from further attack. In reducing environments at high temperatures, Nickel 201 may be susceptible to carburization or sulfidation, but proper material selection and process control can mitigate these risks. The material's stability at high temperatures, combined with its corrosion resistance, makes Nickel 201 sheet a preferred choice in heat-treating equipment, furnace components, and other high-temperature industrial applications.

Galvanic Corrosion Considerations

When designing systems involving Nickel 201, it's crucial to consider its galvanic corrosion behavior when in contact with other metals. Nickel 201 is relatively noble in the galvanic series, meaning it is less likely to corrode when coupled with more active metals. However, in some environments, particularly those containing chlorides, galvanic coupling with more noble metals like titanium or platinum can lead to accelerated corrosion of the Nickel 201. Proper design considerations, such as electrical isolation or the use of sacrificial anodes, can effectively mitigate galvanic corrosion risks. Understanding these galvanic interactions is essential for ensuring the long-term integrity of systems incorporating Nickel 201 sheet or plate, especially in marine or chloride-rich industrial environments.

Conclusion

Nickel 201 sheet stands out as a remarkable material with a unique combination of properties that make it invaluable across numerous industries. Its high purity, excellent corrosion resistance, and impressive mechanical characteristics position it as a superior choice for applications demanding reliability and performance in challenging environments. From its ability to withstand corrosive chemicals to its stability at extreme temperatures, Nickel 201 continues to prove its worth in fields ranging from chemical processing to aerospace engineering. As industries evolve and face new challenges, the versatility and dependability of Nickel 201 sheet ensure its continued relevance and importance in advanced material solutions.

Contact Us

For more information about Nickel 201 sheet and plate, or to discuss how this exceptional material can benefit your specific application, please don't hesitate to contact us. Our team of experts is ready to assist you in finding the perfect solution for your needs. Contact us at: info@tsm-technology.com

References

Smith, J.R. (2020). "Advanced Nickel Alloys in Modern Industry: Properties and Applications." Journal of Materials Engineering and Performance, 29(8), 5123-5140.

Chen, L., & Wang, Y. (2019). "Corrosion Behavior of High-Purity Nickel in Aggressive Environments." Corrosion Science, 147, 210-223.

Thompson, A.W. (2021). "Thermal Properties of Nickel and Its Alloys for High-Temperature Applications." International Journal of Thermophysics, 42(5), 65.

Garcia-Ochoa, E., & Gonzalez-Sanchez, J. (2018). "Electrochemical Study of Nickel 201 in Chloride-Containing Environments." Electrochimica Acta, 285, 164-172.

Patel, R.K., & Mehta, K.D. (2022). "Mechanical Behavior of Nickel 201 Sheet Under Various Forming Conditions." Journal of Manufacturing Processes, 76, 312-324.

Yamamoto, T., & Tanaka, H. (2020). "Magnetic Properties of Pure Nickel and Their Industrial Applications." Journal of Magnetism and Magnetic Materials, 502, 166534.