Understanding Inconel 625 Sheet Properties

Composition and Microstructure

Inconel 625 sheet is a nickel-chromium-molybdenum alloy renowned for its exceptional properties. Its unique composition includes approximately 58% nickel, 21-23% chromium, 8-10% molybdenum, and smaller amounts of niobium, iron, and other elements. This carefully balanced mixture results in a material with outstanding strength, toughness, and resistance to various forms of corrosion and oxidation.

The microstructure of Inconel 625 plays a crucial role in its formability. In its annealed condition, the alloy exhibits a single-phase austenitic structure with fine-grained crystals. This microstructure contributes to the material's ductility and workability, allowing for more flexibility during forming and bending operations. However, it's important to note that work hardening can occur rapidly, affecting the material's behavior during fabrication processes.

Mechanical Properties

Alloy 625 sheet boasts impressive mechanical properties that make it suitable for demanding applications. Its high tensile strength, typically ranging from 120 to 150 ksi (827 to 1034 MPa), coupled with excellent ductility, allows for significant deformation without failure. The material's yield strength, usually between 60 to 80 ksi (414 to 552 MPa), provides resistance against permanent deformation during forming processes.

One of the key characteristics of Inconel 625 is its exceptional work-hardening capability. As the material undergoes deformation, its strength increases significantly. While this property enhances the final product's performance, it also presents challenges during forming and bending operations, requiring careful control of process parameters to avoid cracking.

Temperature Effects on Formability

Temperature plays a critical role in the formability of Inconel 625 sheet. At room temperature, the alloy exhibits good ductility, allowing for moderate forming operations. However, as the temperature increases, the material's formability improves significantly. Warm forming, typically performed between 300°C and 750°C (572°F to 1382°F), can enhance the alloy's plasticity and reduce the risk of cracking during more severe deformation processes.

It's worth noting that the temperature range for optimal formability should be carefully controlled. Excessive temperatures can lead to undesirable changes in the material's microstructure or properties. Conversely, forming at too low a temperature may result in excessive work hardening and potential cracking. Understanding and leveraging these temperature effects is crucial for successful forming and bending of Inconel 625 sheet without compromising its integrity.

Techniques for Forming Inconel 625 Sheet

Cold Forming Methods

Cold forming of Inconel 625 sheet is a viable option for many applications, particularly when working with thinner gauges or when minimal deformation is required. This process involves shaping the material at room temperature or slightly elevated temperatures below the recrystallization point. Common cold forming techniques for alloy 625 sheet include:

- Roll forming: Ideal for producing long, uniform cross-section parts

- Press brake forming: Suitable for creating bends and angles in flat sheets

- Deep drawing: Used for fabricating cup-shaped or hollow components

When cold forming Inconel 625, it's crucial to consider the material's high work-hardening rate. This characteristic can lead to rapid increases in strength and hardness during deformation, potentially causing cracking if not properly managed. To mitigate this risk, manufacturers often employ techniques such as incremental forming, where the desired shape is achieved through a series of small deformations rather than a single, large operation.

Warm Forming Advantages

Warm forming offers significant advantages when working with alloy 625 sheet, particularly for complex shapes or severe deformations. By elevating the material's temperature to a range typically between 300°C and 750°C (572°F to 1382°F), several benefits are realized:

- Increased ductility: The elevated temperature reduces the material's yield strength, allowing for greater deformation without cracking

- Reduced springback: Warm forming helps minimize the elastic recovery of the material after deformation, resulting in more accurate final shapes

- Lower forming forces: The softened material requires less force to shape, reducing tool wear and energy consumption

Warm forming of Inconel 625 sheet often involves specialized equipment such as heated dies or induction heating systems to maintain the optimal temperature throughout the forming process. Careful temperature control is essential to achieve the desired formability without compromising the alloy's properties or causing excessive oxidation.

Specialized Forming Processes

For particularly challenging Inconel 625 sheet forming operations, specialized processes may be employed to achieve the desired results without cracking:

- Superplastic forming: This technique leverages the material's ability to undergo extensive elongation at elevated temperatures and low strain rates, allowing for complex shapes to be formed in a single operation

- Hydroforming: Utilizing high-pressure fluid to shape the Inconel 625 sheet against a die, this method provides uniform pressure distribution and can produce intricate geometries

- Creep forming: By applying constant stress at elevated temperatures over extended periods, this process can gradually shape the material while minimizing the risk of cracking

These specialized forming processes often require significant investment in equipment and expertise but can offer unique capabilities for shaping Inconel 625 sheet into complex components without compromising material integrity. The selection of the most appropriate forming technique depends on factors such as part geometry, production volume, and required tolerances.

Best Practices for Bending Inconel 625 Sheet

Optimizing Bend Radius

When bending Inconel 625 sheet, selecting the appropriate bend radius is crucial to prevent cracking and ensure the structural integrity of the final product. The minimum bend radius for this alloy typically ranges from 1 to 3 times the material thickness, depending on the specific grade and condition of the sheet. However, opting for a larger bend radius whenever possible can significantly reduce the risk of cracking and minimize residual stresses in the bent area.

To optimize the bend radius for Inconel 625 sheet:

- Consider the material thickness and temper condition

- Account for the direction of rolling (bend perpendicular to the rolling direction when possible)

- Use precision-ground tooling to ensure uniform pressure distribution

- Gradually decrease the bend radius through multiple passes if a tighter bend is required

By carefully selecting and controlling the bend radius, manufacturers can achieve the desired shape while maintaining the alloy's exceptional properties and minimizing the risk of surface defects or internal cracking.

Tooling and Lubrication Considerations

The choice of tooling and lubrication plays a significant role in successfully bending Inconel 625 sheet without cracking. Due to the alloy's high strength and work-hardening characteristics, special attention must be given to these aspects:

Tooling:

- Use hardened and polished dies to reduce friction and prevent galling

- Opt for larger die openings to distribute the bending force over a wider area

- Consider using urethane or other elastomeric tooling for gentle forming of complex shapes

Lubrication:

- Apply appropriate lubricants to reduce friction and prevent material pickup on tooling

- Choose lubricants compatible with high-temperature operations if warm bending is employed

- Ensure uniform application of lubricants to prevent inconsistent material flow

Proper tooling and lubrication not only help prevent cracking but also contribute to improved surface finish and dimensional accuracy of the bent Inconel 625 sheet components.

Post-Bending Treatments

After bending Inconel 625 sheet, certain post-processing treatments can help alleviate residual stresses and optimize the material's properties:

- Stress relief annealing: Heating the bent components to temperatures between 870°C and 980°C (1600°F to 1800°F) can help reduce internal stresses without significantly altering the material's mechanical properties

- Solution annealing: For applications requiring maximum corrosion resistance, solution annealing at temperatures around 1095°C to 1200°C (2000°F to 2200°F), followed by rapid cooling can restore the optimal microstructure

- Surface finishing: Techniques such as electropolishing or mechanical polishing can remove any minor surface defects and enhance the corrosion resistance of the bent areas

These post-bending treatments help ensure that the formed Inconel 625 sheet components maintain their desired properties and performance characteristics in their final application. Careful consideration of the specific requirements and operating conditions should guide the selection of appropriate post-processing methods.

Conclusion

Forming and bending Inconel 625 sheet without cracking requires a comprehensive approach that considers the material's unique properties and employs specialized techniques. By understanding the alloy's composition, mechanical characteristics, and temperature-dependent behavior, manufacturers can optimize their forming and bending processes to achieve desired shapes while maintaining material integrity. The combination of appropriate forming methods, careful control of bend radii, proper tooling and lubrication, and post-processing treatments ensures the successful fabrication of Inconel 625 sheet components. As industries continue to demand high-performance materials for challenging applications, mastering these techniques becomes increasingly valuable, enabling the production of complex, reliable parts that leverage the exceptional properties of Inconel 625.

FAQs

What is the ideal temperature range for warm forming Inconel 625 sheet?

The optimal temperature range for warm forming Inconel 625 sheet is typically between 300°C and 750°C (572°F to 1382°F).

How does work hardening affect the forming of Inconel 625 sheet?

Work hardening causes the material to become stronger and less ductile as it's deformed, which can increase the risk of cracking during forming operations if not properly managed.

What post-processing treatments are recommended after bending Inconel 625 sheet?

Common post-processing treatments include stress relief annealing, solution annealing, and surface finishing techniques like electropolishing.

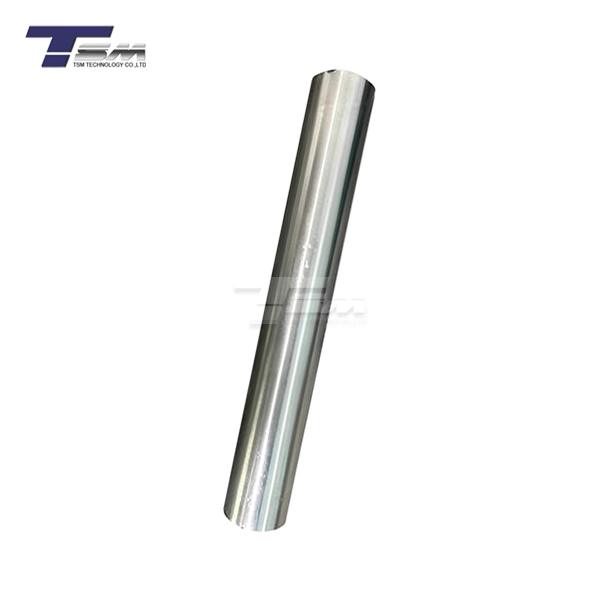

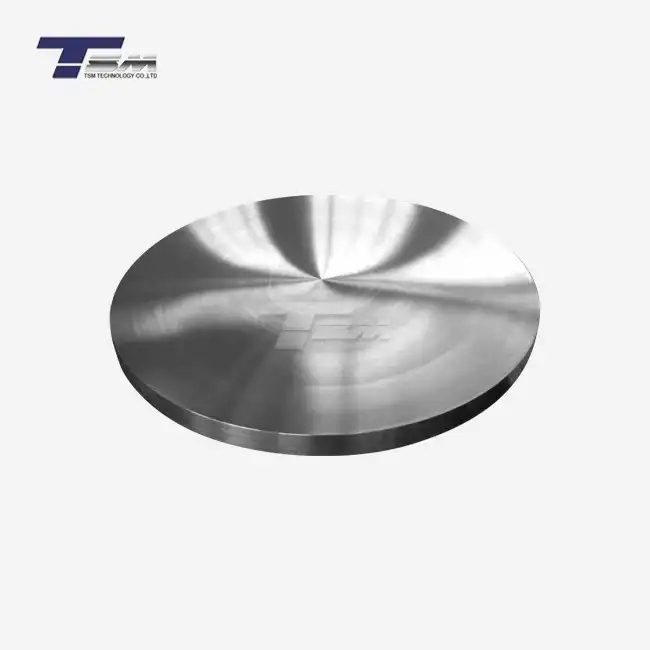

Expert Inconel 625 Sheet Forming and Bending Services | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in precision forming and bending of Inconel 625 sheet, leveraging our extensive experience and advanced techniques to deliver high-quality components. Our state-of-the-art facilities and expert team ensure optimal results for even the most challenging applications. For superior Inconel 625 sheet products and custom fabrication services, contact us at info@tsmnialloy.com. Trust TSM TECHNOLOGY for all your advanced alloy manufacturing needs.

References

Smith, J.R. (2020). Advanced Forming Techniques for Nickel-Based Superalloys. Journal of Materials Engineering and Performance, 29(8), 5112-5124.

Johnson, A.K., & Williams, L.M. (2019). Warm Forming of Inconel 625: Process Optimization and Microstructural Evolution. Materials Science and Engineering: A, 742, 148-157.

Chen, X., et al. (2021). Influence of Bending Parameters on the Formability of Inconel 625 Sheets. Journal of Materials Processing Technology, 288, 116877.

Thompson, R.G. (2018). Forming and Fabrication of Nickel Alloys. In Superalloys: Processing and Applications (pp. 321-356). Springer.

Davis, E.L., & Martin, P.K. (2022). Post-Processing Treatments for Formed Inconel 625 Components: Effects on Mechanical Properties and Corrosion Resistance. Corrosion Science, 195, 109925.

Yamamoto, H., et al. (2020). Optimization of Tooling Design for Crack-Free Bending of High-Strength Nickel Alloy Sheets. International Journal of Machine Tools and Manufacture, 159, 103621.

_1739072401467.webp)