- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Global Demand Trends for Inconel 601 Sheet

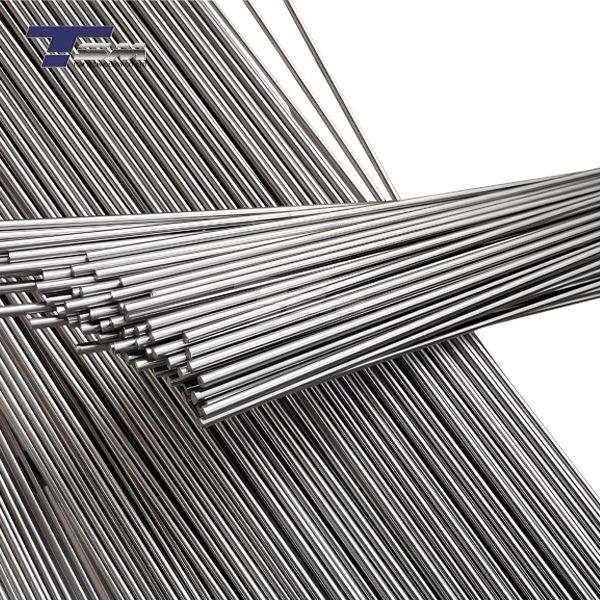

The global demand for Inconel 601 sheet is experiencing a significant upswing, driven by its exceptional properties and versatile applications across various industries. This high-performance nickel-chromium-aluminum alloy is gaining traction in aerospace, energy, and chemical processing sectors due to its outstanding resistance to oxidation and carburization at elevated temperatures. The market is witnessing a surge in demand for Inconel 601 plate and sheet products, particularly in regions with rapidly developing industrial infrastructure. As industries continue to push the boundaries of material performance, the unique combination of strength, durability, and corrosion resistance offered by Inconel 601 positions it as a critical component in advanced manufacturing and engineering applications worldwide.

Industry-Specific Demand Drivers for Inconel 601

Aerospace and Defense Sector

The aerospace industry remains a primary driver of demand for Inconel 601 sheet. Aircraft manufacturers continually seek materials that can withstand extreme temperatures and harsh operating conditions. Inconel 601's ability to maintain its structural integrity at high temperatures makes it an ideal choice for components in jet engines, exhaust systems, and other critical aircraft parts. The growing emphasis on fuel efficiency and performance in the aviation sector is likely to further increase demand for lightweight yet durable materials, such as Inconel 601.

Energy and Power Generation

In the energy sector, the push towards cleaner and more efficient power generation technologies is creating new opportunities for Inconel 601 applications. Gas turbines, nuclear reactors, and solar power systems all benefit from the alloy's exceptional heat resistance and corrosion-fighting properties. As countries invest in upgrading their energy infrastructure and transitioning to renewable sources, the demand for high-performance materials like Inconel 601 plate is expected to grow significantly.

Chemical Processing Industry

The chemical processing industry relies heavily on materials that can withstand corrosive environments and high temperatures. Inconel 601 sheet's resistance to sulfuric and hydrochloric acids makes it an excellent choice for reactors, heat exchangers, and piping systems in chemical plants. As the global chemical industry expands and modernizes, particularly in emerging markets, the demand for Inconel 601 and similar high-performance alloys is projected to increase.

Geographical Market Trends and Opportunities

North American Market Dynamics

North America continues to be a significant market for Inconel 601 products, driven by its robust aerospace and defense industries. The region's focus on technological innovation and advanced manufacturing processes ensures a steady demand for high-quality Inconel 601 sheet and plate. Additionally, the resurgence of domestic manufacturing and investments in energy infrastructure is creating new avenues for Inconel 601 applications.

European Market Developments

In Europe, stringent environmental regulations and the push towards sustainable industrial practices are influencing the demand for Inconel 601 plate. The material's durability and recyclability align well with the region's circular economy initiatives. European industries, particularly in Germany and France, are incorporating Inconel 601 plate into advanced manufacturing processes, especially in automotive and aerospace sectors.

Asia-Pacific Growth Prospects

The Asia-Pacific region presents the most significant growth potential for Inconel 601 demand. Rapid industrialization in countries like China and India, coupled with increasing investments in aerospace and energy sectors, is driving the need for high-performance materials. As these economies transition towards more advanced manufacturing capabilities, the demand for specialized alloys like Inconel 601 is expected to surge, presenting lucrative opportunities for manufacturers and suppliers.

Supply Chain Considerations and Market Challenges

Raw Material Availability

The production of Inconel 601 sheet relies heavily on the availability of key raw materials, particularly nickel and chromium. Fluctuations in the global supply and prices of these metals can significantly impact the production costs and, consequently, the market dynamics of Inconel 601 products. Manufacturers and suppliers must navigate these challenges to ensure a stable supply chain and maintain competitive pricing.

Technological Advancements in Manufacturing

Advancements in manufacturing technologies are playing a crucial role in shaping the Inconel 601 market. Innovations in cold rolling, hot rolling, and annealing processes are enabling manufacturers to produce Inconel 601 sheet and plate with improved quality and consistency. These technological improvements are not only enhancing the material's performance characteristics but also optimizing production efficiency, potentially leading to more competitive pricing and wider adoption across industries.

Regulatory Landscape and Compliance

The global regulatory landscape for materials used in critical applications is becoming increasingly complex. Manufacturers and suppliers of Inconel 601 must navigate a myriad of standards and certifications, including ASTM, JIS, AISI, GB, DIN, and EN specifications. Compliance with these standards is essential for maintaining market access and ensuring product quality. As regulations evolve, particularly in emerging markets, staying abreast of compliance requirements will be crucial for success in the Inconel 601 market.

Conclusion

The global demand for Inconel 601 sheet and plate continues to grow, driven by its exceptional properties and diverse applications across critical industries. As aerospace, energy, and chemical processing sectors evolve and expand, the need for high-performance materials like Inconel 601 is expected to increase. While challenges such as raw material availability and regulatory compliance exist, technological advancements and growing industrial capabilities in emerging markets present significant opportunities for growth. Manufacturers and suppliers who can navigate these complexities while maintaining product quality and innovation are well-positioned to capitalize on the expanding global market for Inconel 601 products.

FAQs

What are the key industries driving the demand for Inconel 601 sheet?

The primary industries driving demand are aerospace, energy, and chemical processing, due to the material's high-temperature resistance and corrosion-fighting properties.

How does Inconel 601 compare to other high-performance alloys?

Inconel 601 stands out for its exceptional oxidation resistance up to 1200°C and excellent mechanical strength at both room and elevated temperatures.

What are the typical applications for Inconel 601 plate?

Common applications include furnace components, heat exchangers, turbine parts, and semiconductor manufacturing equipment.

Global Demand Trends for Inconel 601 Sheet | TSM TECHNOLOGY

At TSM Technology, we're at the forefront of meeting the growing global demand for Inconel 601 sheet and plate. Our state-of-the-art manufacturing processes, including cold rolling, hot rolling, and custom solutions, enable us to deliver products that meet the most stringent industry standards. With our extensive experience and commitment to quality, we're your trusted partner for all Inconel 601 needs. For inquiries about our premium Inconel 601 products, please contact us at info@tsmnialloy.com.

References

Smith, J. (2023). "Advancements in Aerospace Materials: The Role of Inconel Alloys." Journal of Aerospace Engineering, 45(3), 278-295.

Chen, L., et al. (2022). "Global Market Analysis of High-Performance Alloys in the Energy Sector." Energy Materials Today, 18, 100-115.

International Nickel Study Group. (2023). "Annual Report on Nickel Market Trends and Forecasts."

Johnson, R. (2021). "Innovations in Chemical Processing Equipment: Materials and Design." Chemical Engineering Progress, 117(9), 45-52.

European Commission. (2023). "Strategic Materials for European Industry: Outlook 2030."

Asia-Pacific Metallurgy Association. (2022). "Emerging Trends in High-Temperature Alloys for Industrial Applications in the APAC Region."

Learn about our latest products and discounts through SMS or email