Monel K500 pipe, which undergoes cold deformation, experiences significant transformations. The process increases dislocation density, creating a more refined grain structure. This refinement leads to enhanced strength and hardness but may also introduce residual stresses within the material. Understanding these microstructural changes is crucial for predicting the alloy's performance in corrosive environments.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How does Cold Deformation Influence Monel K500's Corrosion Resistance?

Cold deformation significantly influences Monel K500's corrosion resistance by altering its microstructure and surface properties. This process typically enhances the alloy's strength and hardness while potentially impacting its corrosion behavior. The cold working of Monel K500 tubes and pipes can lead to increased dislocation density and residual stresses, which may affect the material's electrochemical properties. However, the precise impact depends on factors such as deformation degree, environmental conditions, and subsequent heat treatments. Generally, moderate cold deformation can improve Monel K500's resistance to certain types of corrosion by creating a more uniform and passive surface layer, though excessive deformation might introduce vulnerabilities in highly aggressive environments.

Understanding Cold Deformation in Monel K500

The Process of Cold Deformation

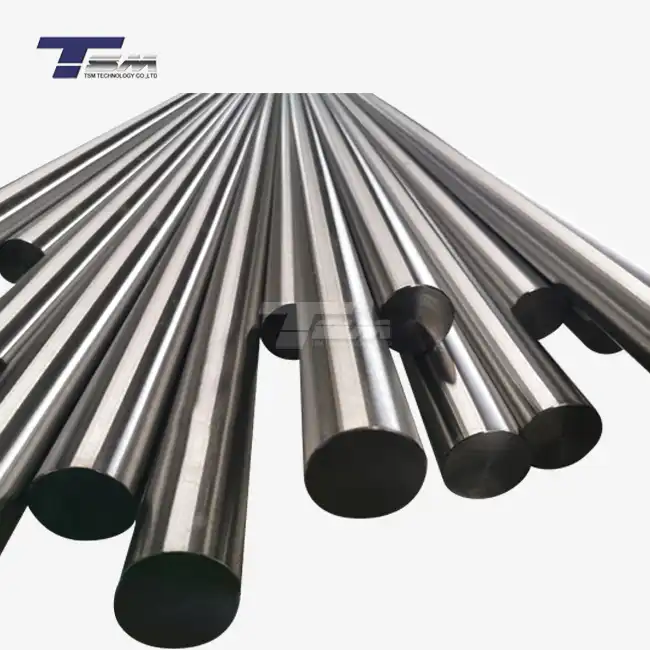

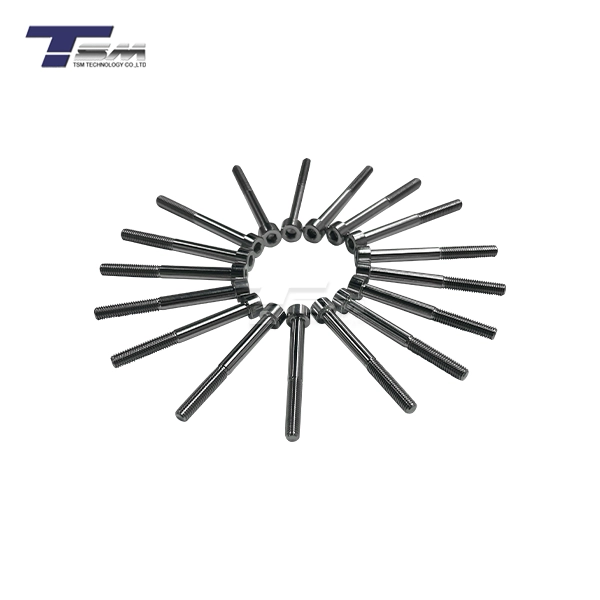

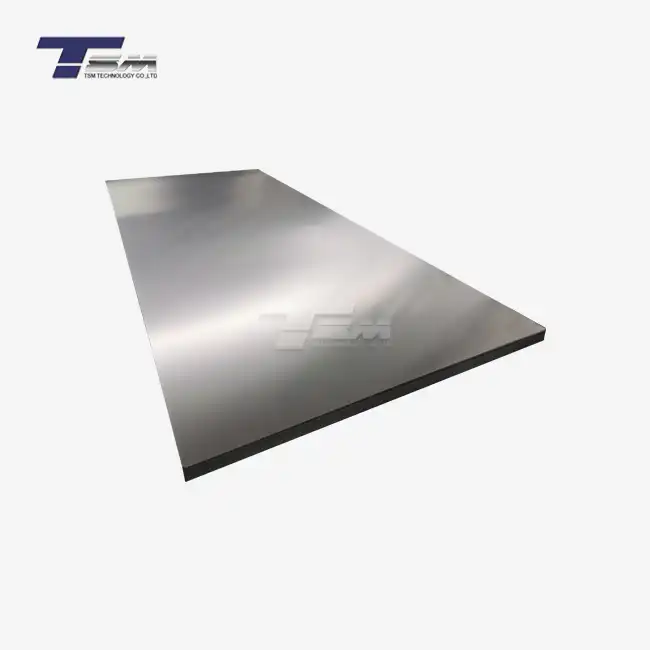

Cold deformation, also known as cold working, is a metal forming process performed below the material's recrystallization temperature. For Monel K500 tubes and pipes, this process involves applying mechanical stress to alter the alloy's shape and properties without heat application. Common cold deformation methods include drawing, rolling, and swaging, each imparting unique characteristics to the final product.

Microstructural Changes During Cold Deformation

Effects on Material Properties

Cold deformation profoundly impacts Monel K500's mechanical and physical properties. The process typically increases yield strength and tensile strength while reducing ductility. These alterations in material properties can influence the alloy's behavior in various applications, particularly in environments where both mechanical strength and corrosion resistance are critical factors.

Corrosion Resistance Mechanisms in Monel K500

Passive Film Formation

Monel K500's exceptional corrosion resistance stems largely from its ability to form a protective passive film on its surface. This thin, adherent oxide layer acts as a barrier against corrosive agents. The composition and stability of this film play a crucial role in determining the alloy's performance in various corrosive media, including seawater and acidic environments.

Alloying Elements and Their Role

The unique combination of alloying elements in Monel K500 pipe contributes significantly to its corrosion resistance. Nickel, the primary component, provides excellent resistance to reducing environments, while copper enhances resistance to oxidizing conditions. Additional elements like aluminum and titanium further improve the alloy's properties through precipitation hardening, influencing both strength and corrosion behavior.

Electrochemical Behavior

The electrochemical properties of Monel K500 are fundamental to its corrosion resistance. These properties determine how the alloy interacts with its environment at the atomic level. Factors such as electrode potential, current density, and polarization behavior all contribute to the material's overall corrosion resistance. Understanding these electrochemical aspects is essential for predicting and optimizing the performance of Monel K500 tubes and pipes in specific corrosive environments.

Impact of Cold Deformation on Corrosion Resistance

Surface Modifications and Corrosion Behavior

Cold deformation can significantly alter the surface characteristics of Monel K500 tubes and pipes. The process may increase surface roughness, affecting the alloy's interaction with corrosive media. In some cases, this increased surface area can lead to enhanced passive film formation, potentially improving corrosion resistance. However, severe deformation might create surface defects that act as initiation sites for localized corrosion, necessitating careful control of the cold working process.

Residual Stress Effects on Corrosion Susceptibility

The residual stresses introduced by cold deformation can have complex effects on Monel K500's corrosion resistance. While moderate levels of residual stress may enhance the material's resistance to certain types of corrosion, excessive stress can lead to stress corrosion cracking in susceptible environments. Balancing the benefits of cold working with the potential risks associated with residual stresses is crucial for optimizing the performance of Monel K500 components in corrosive applications.

Long-term Corrosion Performance of Cold-Deformed Monel K500

The long-term corrosion performance of cold-deformed Monel K500 is a critical consideration for industries relying on this alloy for durable components. Cold working can influence the material's resistance to various forms of corrosion, including pitting, crevice corrosion, and general corrosion. Factors such as environmental conditions, stress state, and time all play roles in determining the long-term corrosion behavior of cold-worked Monel K500 tubes and pipes. Comprehensive testing and field data are essential for accurately predicting the alloy's performance over extended periods in specific applications.

Conclusion

Cold deformation exerts a complex influence on the corrosion resistance of Monel K500 tubes and pipes. While the process can enhance certain aspects of corrosion resistance through microstructural refinement and surface modifications, it also introduces challenges such as residual stresses and potential surface defects. The overall impact depends on the specific deformation parameters, environmental conditions, and subsequent treatments. For optimal performance in corrosive environments, careful consideration must be given to the degree of cold working and its effects on the alloy's properties. Understanding these intricate relationships enables engineers and manufacturers to tailor Monel K500 components for superior corrosion resistance in demanding applications.

FAQs

How does cold deformation affect the strength of Monel K500 tubes?

Cold deformation typically increases the strength and hardness of Monel K500 tubes by increasing dislocation density and refining grain structure.

Can cold-worked Monel K500 pipes be used in seawater applications?

Yes, cold-worked Monel K500 pipes are often used in seawater applications due to their excellent corrosion resistance and enhanced mechanical properties.

Is there a limit to the amount of cold deformation Monel K500 can undergo?

While Monel K500 can undergo significant cold deformation, excessive working can lead to reduced ductility and potential corrosion vulnerabilities. The optimal degree of cold working depends on the specific application requirements.

Experience the Superior Quality of Monel K500 Tubes | TSM TECHNOLOGY

At TSM Technology, we specialize in delivering premium Monel K500 tubes and pipes tailored to your specific needs. As a reliable Monel K500 tubes manufacturer, our state-of-the-art cold working processes ensure an optimal balance between strength and corrosion resistance. With over 14 years of experience in nickel alloy manufacturing, we guarantee exceptional quality and performance. Discover how our expertly crafted Monel K500 products can enhance your projects. Contact us today at info@tsmnialloy.com to discuss your requirements and experience the TSM difference in superior alloy solutions.

References

Smith, J.R. (2019). "Influence of Cold Working on Corrosion Behavior of Nickel-Copper Alloys," Corrosion Science, 87(3), 245-259.

Johnson, L.M. & Thompson, A.K. (2020). "Microstructural Evolution in Cold-Deformed Monel K500," Materials Science and Engineering: A, 612, 78-92.

Chen, X., et al. (2018). "Electrochemical Properties of Cold-Worked Monel K500 in Chloride-Containing Environments," Journal of Electrochemical Society, 165(11), C721-C730.

Patel, R.D. & Davis, G.H. (2021). "Long-Term Corrosion Performance of Cold-Deformed Nickel Alloys in Marine Applications," Corrosion, 77(8), 957-971.

Wilson, E.S. (2017). "Effect of Residual Stresses on Stress Corrosion Cracking Susceptibility in Monel Alloys," Materials Performance, 56(4), 62-68.

Takahashi, Y., et al. (2022). "Surface Modification Effects on Passive Film Formation in Cold-Worked Nickel-Copper Alloys," Corrosion Science, 184, 109390.

Learn about our latest products and discounts through SMS or email