- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Hardness Testing Procedures for Nickel Alloy Plate

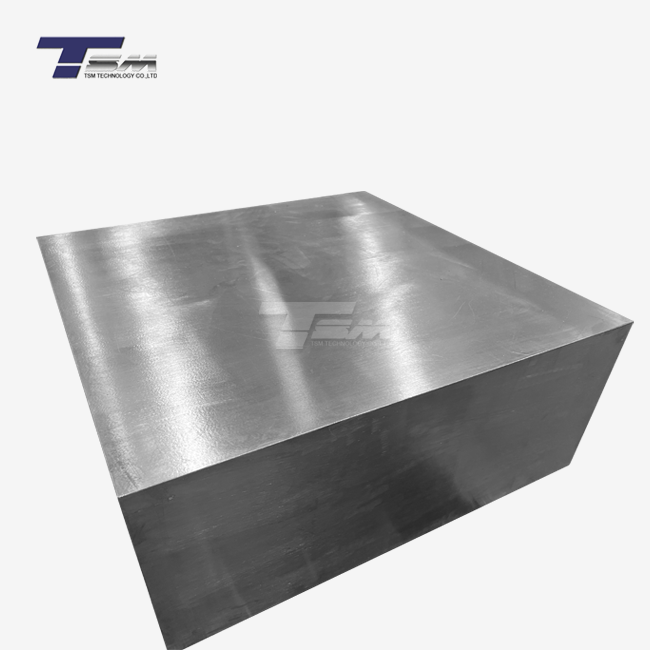

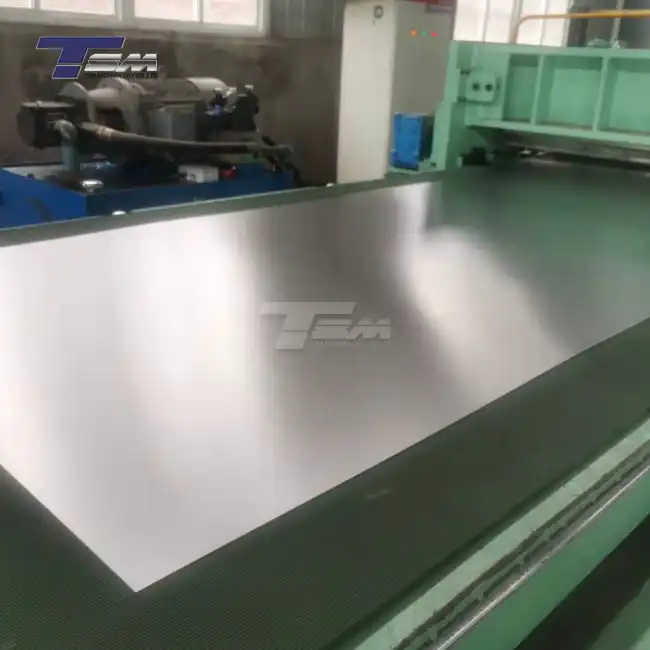

Hardness testing is a crucial quality control measure for nickel alloy plates, ensuring their suitability for demanding applications in aerospace, energy, and chemical industries. These procedures involve various methods such as Brinell, Rockwell, and Vickers tests, each designed to evaluate the material's resistance to indentation. For nickel alloy plates, which often require precise hardness levels to maintain their exceptional strength and corrosion resistance, accurate testing is essential. The process typically includes surface preparation, calibration of testing equipment, and careful interpretation of results to guarantee that the plates meet industry standards and customer specifications.

Understanding Nickel Alloy Plate Hardness

Importance of Hardness in Nickel Alloys

Hardness plays a fundamental role in defining the operational reliability of nickel alloy plates across demanding industries. Elevated hardness levels often translate into superior resistance to wear, abrasion, and deformation under stress, which is particularly valuable in high-performance environments such as turbine blades, reactors, and chemical processing units. However, there is no universal level of hardness that fits all applications. Instead, the ideal hardness must be carefully matched to the alloy’s composition and intended function, making precise hardness testing essential.

Factors Affecting Hardness in Nickel Alloy Plates

Several factors contribute to the hardness of nickel alloy plates:

- Alloy composition: The precise blend of nickel with elements like chromium, molybdenum, and cobalt significantly impacts hardness.

- Heat treatment: Processes like solution annealing and age hardening can alter the microstructure and, consequently, the hardness.

- Cold working: Manufacturing techniques such as rolling can increase hardness through work hardening.

- Grain size: Finer grain structures typically result in higher hardness values.

Relationship Between Hardness and Other Properties

Hardness in nickel alloy plates is often correlated with other mechanical properties:

- Tensile strength: Generally, higher hardness indicates higher tensile strength.

- Ductility: An inverse relationship often exists between hardness and ductility.

- Wear resistance: Harder materials typically exhibit better resistance to abrasion and wear.

Understanding these relationships helps in predicting overall material performance based on hardness test results.

Common Hardness Testing Methods for Nickel Alloy Plates

Brinell Hardness Test

The Brinell hardness test is one of the most widely applied methods for evaluating nickel alloy plates, particularly thicker sections, as it provides reliable hardness measurements under heavy load conditions.It involves:

- Applying a load (typically 3000 kgf) through a hardened steel ball indenter.

- Measuring the diameter of the resulting indentation.

- Calculating the Brinell Hardness Number (BHN) based on the load and indentation size.

This method provides a good average hardness value over a larger area, making it suitable for materials with non-uniform structures.

Rockwell Hardness Test

The Rockwell test is popular for its speed and simplicity in providing quick and reliable hardness measurements across a wide range of nickel alloy plates:

- It uses either a diamond cone or hardened steel ball indenter.

- The test measures the depth of indentation under a specified load.

- Common scales for nickel alloys include HRC (Rockwell C) and HRB (Rockwell B).

Rockwell testing is particularly useful for quality control due to its ease of use and ability to perform multiple tests quickly.

Vickers Hardness Test

The Vickers test offers high precision and is suitable for a wide range of hardness values:

- It uses a diamond pyramid indenter.

- The test can be performed with various loads, making it versatile for different plate thicknesses.

- Hardness is calculated based on the indentation's diagonal length.

Vickers testing is ideal for thin nickel alloy plates or when precise measurements are required, such as in aerospace applications.

Procedures for Conducting Hardness Tests on Nickel Alloy Plates

Sample Preparation

Proper sample preparation is crucial for accurate hardness testing of nickel alloy plates:

- Surface cleaning: Remove any oxidation, scale, or contaminants.

- Polishing: Achieve a smooth, flat surface to ensure consistent indentation.

- Thickness consideration: Ensure the plate is thick enough to support the test without influence from the underlying support.

- Temperature control: Conduct tests at room temperature unless specific temperature conditions are required.

Test Equipment Calibration

Calibration is essential for reliable hardness measurements:

- Use certified calibration blocks specific to the hardness scale being used.

- Perform daily verification tests on standard blocks.

- Ensure proper indenter condition and cleanliness.

- Regularly service and calibrate the testing machine according to manufacturer guidelines and industry standards.

Test Execution and Result Interpretation

Conducting the test and interpreting results requires attention to detail:

- Select appropriate test parameters (load, dwell time) based on the nickel alloy type and plate thickness.

- Perform multiple tests at different locations on the plate to account for potential variations.

- Calculate the average hardness value and standard deviation.

- Compare results with specified requirements or industry standards.

- Document all test conditions, including the specific alloy composition and any heat treatments applied.

Conclusion

Hardness testing is a fundamental aspect of quality control for nickel alloy plates, providing crucial insights into material properties and performance expectations. By adhering to standardized procedures and selecting the appropriate testing method, manufacturers and end-users can ensure the reliability and suitability of nickel alloy plates for their intended applications. As industries continue to demand materials capable of withstanding extreme conditions, precise hardness testing remains an indispensable tool in verifying the exceptional qualities of nickel alloy plates.

FAQs

How often should hardness tests be performed on nickel alloy plates?

Frequency depends on production volume and specific industry requirements, but typically includes testing each batch or heat treatment lot.

Can hardness testing damage the nickel alloy plate?

Properly conducted tests leave only microscopic indentations that don't affect overall plate integrity.

What's the difference between macro and micro hardness tests for nickel alloys?

Macro tests use higher loads and are suitable for bulk properties, while micro tests use lower loads for thin plates or specific microstructural features.

Hardness Testing Procedures for Nickel Alloy Plate | TSM TECHNOLOGY

At TSM Technology, we employ state-of-the-art hardness testing procedures for our nickel alloy plates, ensuring top-quality products for our global customers. Our rigorous testing protocols, combined with our extensive experience in manufacturing superior alloys, guarantee that every plate meets or exceeds industry standards. For inquiries about our nickel alloy plates or testing procedures, please contact us at info@tsmnialloy.com. Trust TSM Technology for unparalleled quality in nickel alloy solutions.

References

ASTM E10-18: Standard Test Method for Brinell Hardness of Metallic Materials

ASTM E18-20: Standard Test Methods for Rockwell Hardness of Metallic Materials

ASTM E92-17: Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials

ASM Handbook, Volume 8: Mechanical Testing and Evaluation

Nickel Development Institute: Guidelines for the Welded Fabrication of Nickel-containing Materials

International Journal of Metallurgical Engineering: Correlation Between Hardness and Tensile Properties in Modern High-Strength Alloy Steels

Learn about our latest products and discounts through SMS or email