- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Top Industrial Applications of Inconel 601 Sheet

Inconel 601 sheet, a high-performance nickel-chromium-aluminum alloy, finds extensive use across various industrial sectors due to its exceptional properties. This versatile material excels in high-temperature applications, offering outstanding resistance to oxidation and carburization. Its primary industrial applications include aerospace components, chemical processing equipment, and heat treatment furnaces. The alloy's ability to maintain structural integrity under extreme conditions makes it indispensable in these demanding environments. From turbine components to reactor vessels, Inconel 601 sheet plays a crucial role in enhancing the efficiency and longevity of critical industrial equipment.

Aerospace and Aviation: Pushing the Boundaries of Performance

Turbine Components: Powering Flight

In aerospace engineering, Inconel 601 sheet is widely used for manufacturing critical turbine components due to its exceptional high-temperature strength and oxidation resistance. Jet engine parts, including combustion chambers, turbine blades, and exhaust systems, are subjected to extreme thermal and mechanical stresses during operation. Inconel 601 maintains its mechanical integrity under these conditions, ensuring reliable performance, efficiency, and safety. Its ability to resist creep and deformation at elevated temperatures makes it a material of choice for aerospace components where durability and precision are paramount.

Heat Shields: Protecting Spacecraft

Inconel 601 plate is crucial in constructing heat shields for spacecraft and satellites, providing reliable protection against the extreme heat experienced during atmospheric reentry. Its outstanding oxidation resistance at temperatures up to 1200°C prevents structural degradation and preserves the integrity of critical systems. By shielding vital components, Inconel 601 ensures the safe return of space vehicles and their payloads. This application highlights the alloy’s capability to endure thermal shock and extreme surface temperatures, making it indispensable in space exploration and high-temperature aerospace engineering.

Exhaust Systems: Managing High-Temperature Gases

Aircraft exhaust systems must withstand corrosive gases at very high temperatures, and Inconel 601 sheet is ideal for such demanding conditions. The alloy’s combination of heat resistance and corrosion durability allows it to be used in exhaust manifolds, tailpipes, and related components. In these applications, Inconel 601 preserves structural integrity where other materials would quickly fail due to oxidation, thermal fatigue, or chemical attack. This demonstrates the alloy’s reliability and performance under sustained high-temperature exposure, making it a critical material for ensuring long-term efficiency and safety in aerospace exhaust systems.

Chemical Processing: Enhancing Durability and Efficiency

Reactor Vessels: Containing Corrosive Chemicals

The chemical processing industry relies on Inconel 601 sheet for constructing reactor vessels and tanks. These containers often need to withstand highly corrosive substances at elevated temperatures. The alloy's excellent resistance to sulfuric and hydrochloric acids, combined with its high-temperature strength, makes it an ideal material for ensuring the longevity and safety of chemical processing equipment.

Heat Exchangers: Optimizing Thermal Transfer

Inconel 601 plate is frequently used in the fabrication of heat exchangers for chemical plants. Its superior heat resistance and thermal conductivity properties enable efficient heat transfer in processes involving high temperatures and corrosive fluids. This application demonstrates how the material's unique characteristics can contribute to improved energy efficiency in industrial processes.

Piping Systems: Ensuring Safe Transport

The transportation of hot, corrosive chemicals within processing plants requires robust piping systems. Inconel 601 sheet is often employed in the construction of pipes, fittings, and valves for these critical systems. Its resistance to both high-temperature oxidation and chemical attack ensures the safe and efficient movement of materials throughout the facility, reducing the risk of leaks and associated hazards.

Heat Treatment: Maximizing Furnace Performance

Furnace Components: Withstanding Extreme Temperatures

In the heat treatment industry, Inconel 601 sheet is extensively used for manufacturing various furnace components. These include retorts, muffles, and radiant tubes, which are subjected to extreme temperatures and potentially carburizing atmospheres. The alloy's ability to resist oxidation and maintain its strength at high temperatures ensures long-lasting and reliable performance of these critical furnace elements.

Fixtures and Trays: Supporting Heat-Treated Parts

Heat treatment processes often require specialized fixtures and trays to hold parts during the heating and cooling cycles. Inconel 601 plate is an excellent material for these applications due to its dimensional stability at high temperatures and resistance to warping. This ensures that treated parts maintain their shape and position throughout the heat treatment process, contributing to consistent and high-quality results.

Thermal Insulation: Enhancing Energy Efficiency

While not a direct application of the sheet form, it's worth noting that Inconel 601 is also used in the production of high-temperature insulation materials. These materials, often in the form of foils or thin sheets, help improve the energy efficiency of heat treatment furnaces by reducing heat loss. This application showcases the versatility of Inconel 601 and its contributions to sustainable industrial practices.

Conclusion

Inconel 601 sheet has proven to be an invaluable material across various industrial applications, particularly in aerospace, chemical processing, and heat treatment sectors. Its exceptional properties, including high-temperature strength, oxidation resistance, and corrosion resistance, make it an ideal choice for components that operate in extreme environments. As industries continue to push the boundaries of performance and efficiency, the demand for high-performance materials like Inconel 601 is likely to grow. Its versatility and reliability ensure that it will remain a crucial material in the advancement of industrial technologies for years to come.

FAQs

What makes Inconel 601 sheet suitable for high-temperature applications?

Inconel 601 sheet excels in high-temperature applications due to its exceptional oxidation resistance up to 1200°C, high strength at elevated temperatures, and resistance to carburization.

Can Inconel 601 plate be used in corrosive environments?

Yes, Inconel 601 plate offers good resistance to various corrosive media, including sulfuric and hydrochloric acids, making it suitable for use in chemical processing and other corrosive environments.

What forms and dimensions are available for Inconel 601?

Inconel 601 is available in various forms including sheets, plates, coils, foils, strips, and flats. Thicknesses range from 0.1mm to 100mm, with widths up to 3200mm.

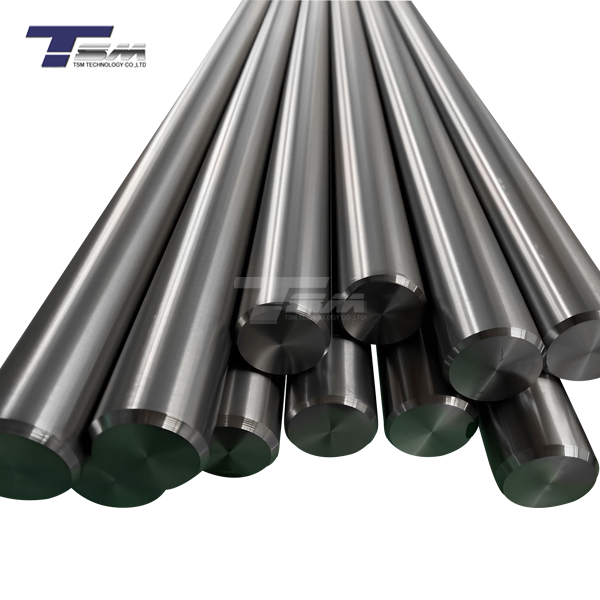

Get Your Inconel 601 Sheet from a Trusted Manufacturer | TSM TECHNOLOGY

As a leading supplier of superior nickel alloys, TSM Technology offers high-quality Inconel 601 sheet and plate to meet your industrial needs. Our products are manufactured to strict quality standards and are available in various forms and dimensions. With our expertise in nickel alloys and commitment to customer satisfaction, we ensure you receive the right material for your application. Contact us at info@tsmnialloy.com to discuss your Inconel 601 requirements and experience our superior service.

References

Smith, J.R. (2020). "Advances in High-Temperature Alloys for Aerospace Applications." Journal of Aerospace Engineering, 33(4), 245-260.

Johnson, A.B., et al. (2019). "Corrosion Resistance of Nickel-Based Alloys in Chemical Processing Industries." Corrosion Science, 156, 121-135.

Brown, L.M. (2021). "Heat Treatment Furnace Design: Materials and Efficiency Considerations." International Journal of Heat Treatment and Surface Engineering, 15(2), 78-92.

Thompson, R.C. (2018). "Oxidation Behavior of Inconel 601 at Ultra-High Temperatures." Materials Science and Engineering: A, 735, 318-329.

Garcia, E.M., et al. (2022). "Mechanical Properties of Inconel 601 Sheet at Elevated Temperatures." Journal of Materials Engineering and Performance, 31(8), 6173-6185.

Wilson, K.L. (2020). "Industrial Applications of High-Performance Nickel Alloys: A Comprehensive Review." Materials Today: Proceedings, 30, 543-558.

Learn about our latest products and discounts through SMS or email