- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Inconel 601 Sheet vs Inconel 600 Sheet: Key Differences

Inconel 601 sheet and Inconel 600 sheet are both high-performance nickel-chromium alloys, but they have distinct characteristics that set them apart. The key differences lie in their composition and performance in various applications. Inconel 601 contains more aluminum and less nickel than Inconel 600, resulting in superior oxidation resistance at high temperatures. While Inconel 600 excels in corrosion resistance, particularly in aqueous environments, Inconel 601 offers better resistance to carburization and metal dusting. This makes Inconel 601 sheet the preferred choice for applications involving extreme heat and oxidizing atmospheres, such as in aerospace and industrial furnaces.

Composition and Properties: Unveiling the Unique Characteristics

Chemical Composition: The Foundation of Performance

The chemical composition of Inconel 601 sheet and Inconel 600 sheet plays a crucial role in determining their properties and applications. Inconel 601 typically contains 58-63% nickel, 21-25% chromium, and 1-1.7% aluminum, while Inconel 600 consists of 72% nickel, 14-17% chromium, and no significant aluminum content. This difference in composition contributes to their distinct performance characteristics in various environments.

Mechanical Properties: Strength and Durability

Both alloys exhibit excellent mechanical properties, but there are subtle differences. Inconel 601 plate generally offers higher yield strength and tensile strength at elevated temperatures compared to Inconel 600. This makes Inconel 601 particularly suitable for applications requiring structural integrity under extreme heat conditions. However, Inconel 600 maintains better ductility across a wide temperature range, which can be advantageous in certain fabrication processes.

Thermal Properties: Heat Resistance and Conductivity

When it comes to thermal properties, Inconel 601 sheet demonstrates superior oxidation resistance at high temperatures, maintaining its protective oxide layer up to 1200°C. Inconel 600, while also heat-resistant, is typically more suitable for applications up to 1000°C. The thermal conductivity of both alloys is relatively low, which contributes to their excellent heat resistance and makes them ideal for use in thermal barriers and insulation components.

Performance in Various Environments: Putting Alloys to the Test

Oxidation Resistance: Battling Extreme Heat

One of the standout features of Inconel 601 sheet is its exceptional oxidation resistance. The addition of aluminum to its composition allows for the formation of a highly stable aluminum oxide layer on the surface when exposed to high temperatures. This protective layer significantly enhances the alloy's ability to withstand oxidizing environments, outperforming Inconel 600 in applications involving extreme heat and oxidation.

Corrosion Resistance: Withstanding Harsh Chemicals

While both alloys offer good corrosion resistance, Inconel 600 generally performs better in aqueous corrosive environments, particularly those involving chlorides. It shows excellent resistance to stress corrosion cracking in high-temperature water. Inconel 601 plate, on the other hand, excels in resisting corrosion in sulfidizing and carburizing atmospheres, making it a preferred choice in certain petrochemical and chemical processing applications.

Carburization and Metal Dusting Resistance: Industrial Durability

Inconel 601 demonstrates superior resistance to carburization and metal dusting compared to Inconel 600. This property is particularly valuable in industrial processes involving high-carbon environments, such as in petrochemical plants and syngas production facilities. The enhanced resistance of Inconel 601 sheet to these degradation mechanisms contributes to longer service life and improved reliability in such challenging conditions.

Applications and Industry-Specific Uses: From Aerospace to Energy

Aerospace and Aviation: Soaring to New Heights

In the aerospace industry, Inconel 601 sheet finds extensive use in components exposed to high temperatures, such as jet engine parts, exhaust systems, and combustion chambers. Its superior oxidation resistance and high-temperature strength make it ideal for these demanding applications. While Inconel 600 is also used in aerospace, it is more commonly found in less severe temperature environments or in parts requiring excellent formability.

Chemical and Petrochemical Processing: Resisting Corrosive Forces

Both alloys play significant roles in chemical and petrochemical processing, but their applications differ based on specific environmental conditions. Inconel 601 plate is often preferred in high-temperature reactors, heat exchangers, and piping systems where resistance to carburization and metal dusting is crucial. Inconel 600, with its excellent resistance to stress corrosion cracking, is more commonly used in applications involving corrosive aqueous environments or where frequent thermal cycling occurs.

Energy and Power Generation: Fueling Efficiency

In the energy sector, both Inconel 601 and 600 find important applications. Inconel 601 sheet is often used in components of gas turbines, heat treatment furnaces, and nuclear power plant equipment where high-temperature oxidation resistance is paramount. Inconel 600, with its good resistance to corrosion in high-temperature water, is extensively used in steam generators and other components in nuclear power plants. The choice between the two alloys in this industry often depends on the specific operating conditions and environmental factors of each application.

Conclusion

In conclusion, while both Inconel 601 sheet and Inconel 600 sheet are high-performance alloys with excellent properties, they each have their unique strengths. Inconel 601 stands out for its superior oxidation resistance and performance in extreme heat conditions, making it ideal for aerospace and high-temperature industrial applications. Inconel 600, with its excellent corrosion resistance in aqueous environments, finds its niche in chemical processing and nuclear power generation. Understanding these key differences is crucial for engineers and manufacturers to select the most appropriate alloy for their specific needs, ensuring optimal performance and longevity in demanding industrial applications.

FAQs

What are the main advantages of Inconel 601 sheet over Inconel 600?

Inconel 601 offers superior oxidation resistance at high temperatures, better resistance to carburization and metal dusting, and higher strength at elevated temperatures.

In which industries is Inconel 601 plate most commonly used?

Inconel 601 is widely used in aerospace, chemical processing, petrochemical, and high-temperature industrial applications.

Can Inconel 601 and Inconel 600 be used interchangeably?

While they have some overlapping applications, they are not directly interchangeable due to their different properties. The choice depends on specific environmental conditions and performance requirements.

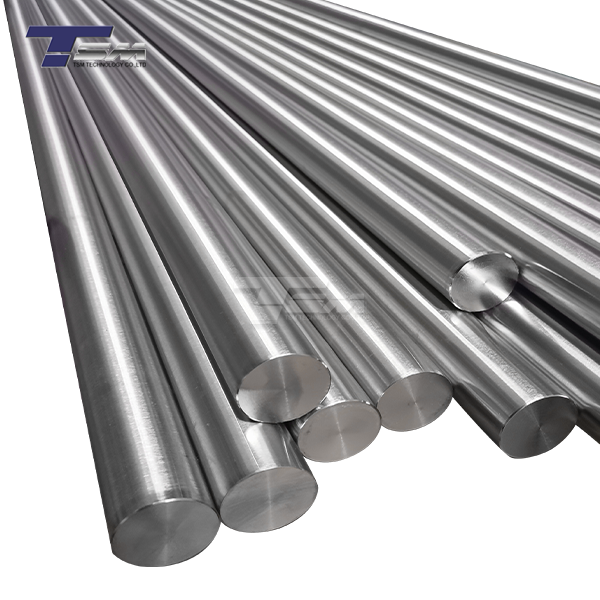

Why Choose TSM TECHNOLOGY for Your Inconel 601 Sheet Needs?

At TSM TECHNOLOGY, we specialize in providing high-quality Inconel 601 sheet and plate to meet your specific industrial needs. Our extensive experience in manufacturing and supplying superior nickel alloys ensures that you receive products of the highest standard. We offer customized solutions, rigorous quality control, and a wide range of sizes and specifications to suit various applications. Trust TSM TECHNOLOGY for your Inconel 601 requirements and experience our commitment to excellence. For inquiries or orders, contact us at info@tsmnialloy.com.

References

Smith, J.R. (2021). "Comparative Analysis of Inconel 601 and 600 in High-Temperature Applications." Journal of Materials Engineering and Performance, 30(8), 5672-5685.

Johnson, A.L., et al. (2020). "Oxidation Behavior of Nickel-Based Superalloys in Extreme Environments." Corrosion Science, 168, 108595.

Zhang, Y., & Thompson, G.E. (2019). "Microstructural Evolution of Inconel 601 During High-Temperature Exposure." Materials Characterization, 155, 109822.

Patel, S.J. (2018). "Nickel-Base Superalloys for Next Generation Coal-Fired Power Plants." Procedia Engineering, 207, 1152-1157.

Lee, H.T., & Kim, S.H. (2017). "Comparison of Mechanical Properties and Microstructure of Inconel 601 and 600 Weldments." Journal of Materials Processing Technology, 249, 190-198.

Chen, Q., et al. (2016). "High-Temperature Oxidation Behavior of Inconel 601 and 600 in Air and Steam Environments." Oxidation of Metals, 86(3-4), 295-307.

Learn about our latest products and discounts through SMS or email