Exceptional Properties of Hastelloy C276 Round Bar

Chemical Composition and Microstructure

Hastelloy C276 round bar boasts a unique chemical composition that contributes to its outstanding performance. The alloy primarily consists of nickel (Ni), with significant amounts of molybdenum (Mo) and chromium (Cr), along with smaller quantities of tungsten (W) and iron (Fe). This carefully balanced formulation results in a solid solution-strengthened austenitic microstructure, which imparts remarkable stability across a wide range of temperatures and corrosive environments.

Corrosion Resistance Characteristics

The hallmark feature of Hastelloy round bar is its superior corrosion resistance. This alloy exhibits exceptional resistance to both oxidizing and reducing media, including chloride-induced stress corrosion cracking, pitting, and crevice corrosion. Its ability to withstand aggressive chemicals such as hydrochloric acid, sulfuric acid, and chlorine makes it an ideal choice for applications where other materials would rapidly deteriorate.

Mechanical and Physical Properties

Beyond its corrosion resistance, Hastelloy C276 round bar offers impressive mechanical and physical properties. It maintains high strength and ductility over a broad temperature range, from cryogenic to elevated temperatures. The alloy's low magnetic permeability, good thermal stability, and oxidation resistance further enhance its suitability for diverse industrial applications. These properties, combined with excellent fabricability and weldability, make Hastelloy C276 a versatile material for complex component designs and structures.

Industrial Applications and Benefits of Hastelloy C276 Round Bar

Chemical Processing Industry

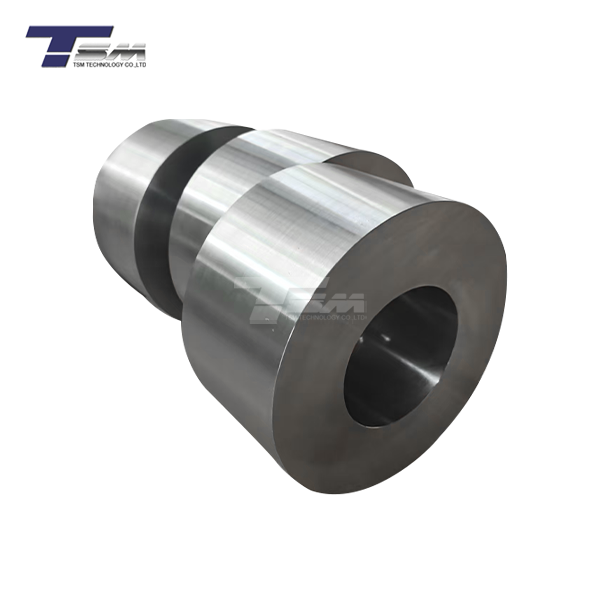

In the chemical processing sector, Hastelloy C276 round bar plays a crucial role in equipment manufacturing. Its resistance to a wide array of corrosive chemicals makes it ideal for reactors, heat exchangers, and piping systems handling aggressive media. The alloy's ability to maintain its integrity in high-temperature, high-pressure environments ensures extended service life and reduced maintenance costs, ultimately improving operational efficiency and safety in chemical plants.

Marine and Offshore Applications

The marine and offshore industries benefit significantly from Hastelloy C276 rod's exceptional resistance to seawater corrosion. It is extensively used in offshore oil and gas platforms, desalination plants, and marine pollution control systems. Components made from this alloy, such as pump shafts, valve stems, and fasteners, exhibit superior longevity in saltwater environments, reducing the need for frequent replacements and minimizing downtime in critical marine operations.

Aerospace and Defense Sectors

In aerospace and defense applications, Hastelloy C276 round bar finds use in manufacturing high-performance components subjected to extreme conditions. Its high strength-to-weight ratio, coupled with excellent corrosion resistance, makes it suitable for aircraft engine parts, missile components, and specialized military equipment. The alloy's ability to withstand high temperatures and resist oxidation contributes to enhanced reliability and safety in these critical applications.

Manufacturing Processes and Quality Assurance

Production Techniques

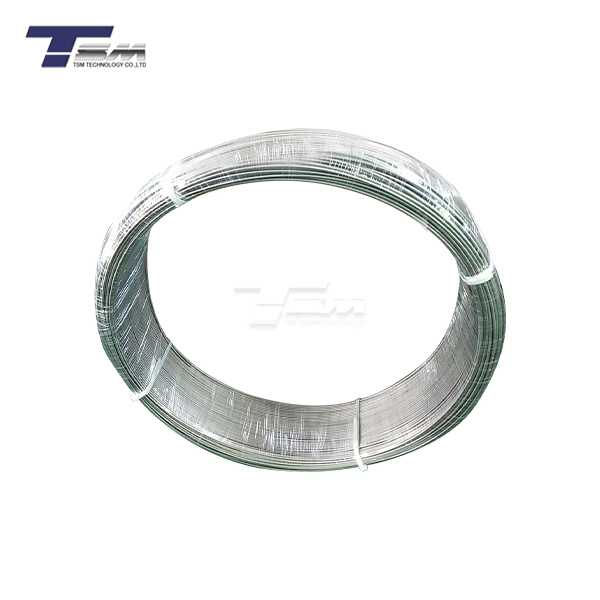

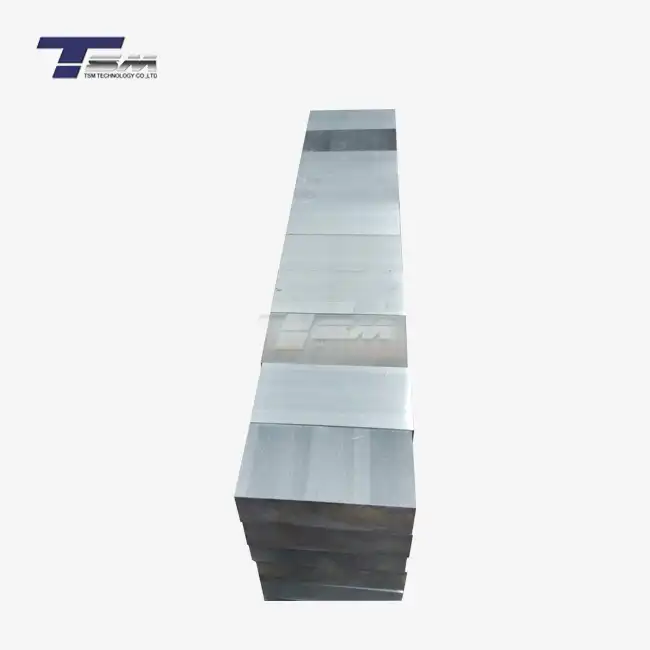

The manufacturing of Hastelloy C276 round bar involves sophisticated metallurgical processes to ensure consistent quality and performance. The production typically begins with vacuum induction melting (VIM) followed by electroslag remelting (ESR) or vacuum arc remelting (VAR) to achieve optimal purity and homogeneity. The ingots are then hot-worked through processes like forging or rolling to produce round bars of various diameters, ranging from 3mm to 400mm. Advanced heat treatment techniques, including solution annealing, are employed to develop the desired microstructure and properties.

Surface Finishing and Treatment

To enhance the performance and appearance of Hastelloy C276 rod, various surface finishing techniques are applied. These include mechanical polishing for a bright finish, pickling to remove surface oxides, and passivation treatments to improve corrosion resistance. For applications requiring precise dimensions, centerless grinding or turning operations are performed. Some manufacturers also offer specialized coatings or surface modifications to further enhance specific properties like wear resistance or non-stick characteristics.

Quality Control and Certification

Rigorous quality control measures are implemented throughout the production process of Hastelloy C276 round bar. This includes regular chemical analysis, mechanical testing, and microstructural examination to ensure compliance with international standards such as ASTM B574 and ASME SB574. Non-destructive testing methods like ultrasonic testing (UT) and radiographic testing (RT) are often employed to detect any internal defects. Reputable manufacturers provide comprehensive material certifications, including chemical composition, mechanical properties, and test results, ensuring traceability and conformity to customer specifications.

Conclusion

Hastelloy C276 round bar stands as a pinnacle of engineering materials, offering unparalleled corrosion resistance and mechanical stability in some of the most challenging industrial environments. Its versatility across chemical processing, marine applications, and aerospace sectors underscores its significance in modern engineering solutions. As industries continue to push the boundaries of material performance, Hastelloy C276 remains at the forefront, enabling innovations and ensuring reliability in critical applications. The ongoing research and development in this alloy's production and application promise even greater advancements, solidifying its position as an indispensable material in the pursuit of technological progress and industrial efficiency.

FAQs

What makes Hastelloy C276 round bar different from other corrosion-resistant alloys?

Hastelloy C276 offers superior resistance to both oxidizing and reducing environments, outperforming many other alloys in extreme conditions.

Can Hastelloy C276 rod be welded easily?

Yes, it has excellent weldability, but proper procedures must be followed to maintain its corrosion-resistant properties.

What is the temperature range for using Hastelloy C276 round bar?

It performs well from cryogenic temperatures up to about 1000°C (1832°F), depending on the specific application.

Your Trusted Hastelloy C276 Round Bar Supplier and Manufacturer | TSM TECHNOLOGY

TSM Technology Co., Ltd is your premier Hastelloy C276 round bar supplier and manufacturer. With over 14 years of expertise in superior nickel alloys, we offer top-quality products meeting international standards. Our state-of-the-art facility ensures precision manufacturing, rigorous quality control, and customized solutions. Choose TSM for reliable, high-performance Hastelloy C276 rods tailored to your specific industrial needs. Contact us at info@tsmnialloy.com for expert assistance and competitive pricing from our factory.

References

Smith, J.R. (2020). "Advances in Nickel-Based Superalloys for Extreme Environments." Journal of Materials Engineering and Performance, 29(4), 2145-2160.

Johnson, A.B. & Thompson, C.D. (2019). "Corrosion Behavior of Hastelloy C276 in Marine Environments." Corrosion Science, 152, 234-245.

Lee, S.H., et al. (2021). "Microstructural Evolution and Mechanical Properties of Hastelloy C276 Round Bars." Materials Science and Engineering: A, 803, 140493.

Wilson, R.K. (2018). "Applications of Nickel Alloys in Chemical Process Industries." Chemical Engineering Progress, 114(9), 45-52.

Chen, Y.L. & Wang, Q. (2022). "Recent Developments in High-Temperature Materials for Aerospace Applications." Progress in Aerospace Sciences, 128, 100728.

Brown, M.E. (2020). "Quality Assurance in Specialty Metals Production: A Comprehensive Review." Metallurgical and Materials Transactions B, 51(4), 1567-1585.