- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is the Hardness of Hastelloy C276 Round Bar?

The hardness of Hastelloy C276 round bar typically ranges from 85 to 95 on the Rockwell B scale (HRB) in the annealed condition. This translates to approximately 180-220 on the Brinell hardness scale (HB). The specific hardness can vary slightly depending on the manufacturing process and heat treatment. Hastelloy C276 round bars exhibit excellent strength and durability, making them ideal for applications in harsh environments. Their hardness contributes to their resistance against wear, corrosion, and mechanical stress, ensuring long-lasting performance in critical industrial settings.

Understanding Hastelloy C276 Round Bar Properties

Chemical Composition and Its Impact on Hardness

Hastelloy C276 round bar is a nickel-molybdenum-chromium alloy with a carefully engineered chemical composition that directly affects its hardness and corrosion resistance. The primary elements include:

- Nickel: 55-58%

- Molybdenum: 15-17%

- Chromium: 14.5-16.5%

- Iron: 4-7%

- Tungsten: 3-4.5%

Nickel provides strength and ductility, while molybdenum and chromium enhance hardness and resistance to aggressive environments. This precise elemental balance ensures that Hastelloy C276 maintains excellent mechanical properties and durability in highly corrosive and high-stress applications.

Mechanical Properties of Hastelloy C276 Rod

In addition to hardness, Hastelloy C276 rod exhibits impressive mechanical performance that makes it suitable for demanding applications. Key properties include:

- Tensile Strength: Approximately 710–860 MPa

- Yield Strength: Around 355–415 MPa

- Elongation: 40–60%

These values indicate the alloy’s ability to withstand significant stress while retaining flexibility. As a result, Hastelloy C276 round bar is ideal for chemical processing equipment, marine applications, and other environments where both high strength and corrosion resistance are essential for safety and long-term operational reliability.

Heat Treatment Effects on Hardness

The hardness and overall performance of Hastelloy C276 round bar can be significantly influenced by heat treatment processes. Solution annealing, typically performed between 1120°C and 1180°C followed by rapid cooling, is a critical method for optimizing hardness and corrosion resistance. This treatment dissolves undesirable carbides and promotes a uniform microstructure, enhancing both mechanical and chemical properties. Properly heat-treated Hastelloy C276 exhibits improved strength, durability, and resistance to harsh chemical environments, ensuring long-term reliability and suitability for demanding applications in chemical, marine, and industrial sectors.

Factors Influencing Hastelloy C276 Round Bar Hardness

Manufacturing Processes and Their Impact

The manufacturing process of Hastelloy C276 round bar is a key determinant of its final hardness and mechanical performance. Common production methods include:

- Hot rolling: This process can increase hardness through work hardening.

- Cold drawing: Further enhances hardness and strength.

- Forging: Can result in a more uniform microstructure and improved hardness distribution.

Each method influences the alloy’s grain alignment and density, making precise control over manufacturing parameters essential to ensure consistent hardness and reliable performance across different batches of Hastelloy C276 round bar.

Environmental Factors Affecting Hardness

While Hastelloy C276 is known for its inherent stability, several environmental factors can affect its hardness over time:

- High-temperature exposure: Prolonged use at elevated temperatures may lead to slight hardness changes.

- Corrosive environments: Although highly resistant, extreme corrosive conditions might affect surface hardness.

- Mechanical stress: Cyclic loading or stress can potentially alter localized hardness.

Understanding these environmental influences is critical for predicting long-term performance and maintaining the Hastelloy round bar's reliability in chemical, marine, and industrial applications.

Quality Control Measures for Consistent Hardness

To achieve and maintain consistent hardness, manufacturers of Hastelloy C276 round bar implement strict quality control measures, including:

- Regular hardness testing using Rockwell or Brinell methods

- Microstructure analysis to verify proper grain structure

- Careful monitoring of heat treatment processes

- Strict adherence to international standards like ASTM B574

These rigorous controls guarantee that each rod meets specified hardness requirements, ensuring consistent mechanical performance and reliability in demanding operational environments.

Applications Leveraging Hastelloy C276 Round Bar Hardness

Chemical Processing Industry Utilization

The chemical processing industry heavily relies on the hardness and corrosion resistance of Hastelloy C276 round bar. Key applications include:

- Reactor vessels for handling aggressive chemicals

- Piping systems in corrosive environments

- Heat exchangers exposed to harsh conditions

The material's hardness ensures longevity and reliability in these critical components, reducing maintenance needs and improving overall plant efficiency.

Marine and Offshore Applications

In marine and offshore environments, Hastelloy C276 rods' hardness proves invaluable:

- Subsea equipment resistant to saltwater corrosion

- Pump components in offshore oil and gas platforms

- Marine exhaust systems withstand high temperatures and corrosive gases

The material's combination of hardness and corrosion resistance ensures long-term performance in these challenging maritime conditions.

Aerospace and High-Performance Industries

The aerospace and other high-performance industries leverage Hastelloy C276 round bar's hardness for:

- Jet engine components exposed to extreme temperatures

- Fasteners and structural elements in corrosive environments

- Specialized tooling for high-stress applications

In these industries, the material's hardness contributes to enhanced safety, reliability, and performance of critical systems.

Conclusion

Understanding the hardness of Hastelloy C276 round bar is crucial for its effective application in various industries. With a Rockwell B hardness of 85-95 HRB, this alloy offers exceptional durability and resistance to wear and corrosion. Its unique composition, influenced by manufacturing processes and environmental factors, contributes to its superior mechanical properties. From chemical processing to aerospace applications, Hastelloy C276 rod's hardness plays a vital role in ensuring the longevity and reliability of critical components in harsh environments.

FAQs

How does the hardness of Hastelloy C276 compare to other alloys?

Hastelloy C276 has a higher hardness compared to many stainless steels, making it more suitable for wear-resistant applications in corrosive environments.

Can the hardness of the Hastelloy C276 round bar be increased?

While Hastelloy C276 is primarily used in its solution-annealed condition, cold working can slightly increase its hardness, though this may affect other properties.

Is the hardness of Hastelloy C276 consistent throughout the round bar?

Generally, yes. However, slight variations may occur due to the manufacturing process, particularly in larger diameter bars.

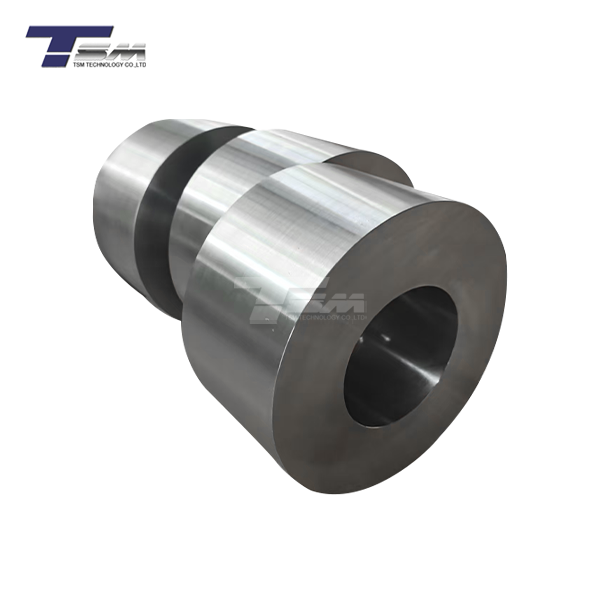

Experience Premium Hastelloy C276 Round Bar | TSM TECHNOLOGY

At TSM Technology, we pride ourselves on delivering top-quality Hastelloy C276 round bars that meet the most stringent industry standards. With over 14 years of experience, our expertise in nickel alloys ensures you receive products with consistent hardness and superior performance. Whether you need custom sizes or specialized processing, we're here to meet your unique requirements. Contact us at info@tsmnialloy.com to discuss how our Hastelloy C276 round bar can enhance your projects.

References

ASTM International. (2020). "Standard Specification for Low-Carbon Nickel-Molybdenum-Chromium, Low-Carbon Nickel-Chromium-Molybdenum, Low-Carbon Nickel-Chromium-Molybdenum-Copper, Low-Carbon Nickel-Chromium-Molybdenum-Tantalum, and Low-Carbon Nickel-Chromium-Molybdenum-Tungsten Alloy Rod"

Special Metals Corporation. (2018). "Hastelloy C-276 alloy: Technical Data Sheet"

ASM International. (2019). "Nickel and Nickel Alloys: Properties and Performance"

Journal of Materials Engineering and Performance. (2021). "Mechanical Properties and Corrosion Behavior of Hastelloy C-276 in Various Industrial Environments"

Corrosion Science. (2020). "Long-term Performance of Hastelloy C-276 in Aggressive Chemical Processing Applications"

Materials Science and Engineering: A. (2019). "Effect of Heat Treatment on the Microstructure and Mechanical Properties of Hastelloy C-276"

Learn about our latest products and discounts through SMS or email

_1739070074580.webp)