- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Heat Treatment of Inconel 690: Solution Annealing for Corrosion Resistance

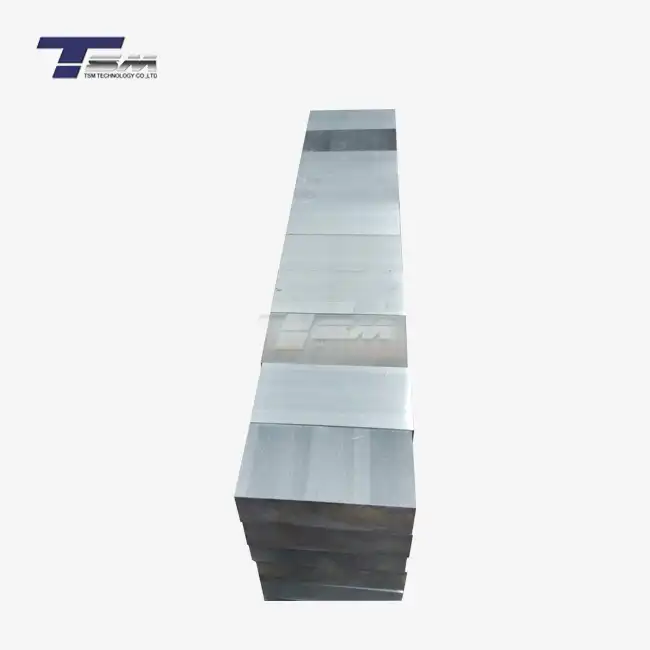

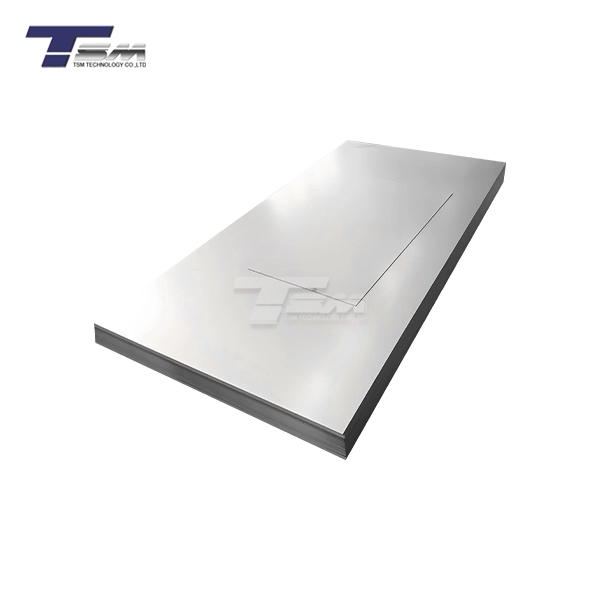

Solution annealing is an important heat treatment method that changes the metal qualities of nickel-chromium alloys, especially when it is used on high-performance materials that are used in tough industrial settings. When working with Inconel 690 sheet, this special heat processing method gets rid of harmful carbide precipitates and improves the microstructure to make it more resistant to rust. The process includes heating the material to high temperatures and then cooling it quickly. This restores the alloy's uniform structure and makes it as strong as possible for use in harsh settings. Engineers and procurement workers need to understand this treatment method in order to make parts last as long as possible in nuclear power, chemical processing, and marine uses where material quality directly affects safety and cost-effectiveness.

Understanding Inconel 690 Sheet and its Key Properties

A carefully measured mix of about 60% nickel, 30% chromium, and 10% iron makes Inconel 690 sheet strong in the metalworking world. There are some amazing things about this nickel-chromium metal that make it very useful in tough industrial settings where other materials don't work.

Chemical Composition and Microstructural Benefits

This superalloy has a lot of chromium, which makes a thick, steady oxide film that is very resistant to many types of corrosive media. When the material comes into contact with oxygen-rich surroundings, this passive layer forms naturally. It acts as a self-healing barrier that shields the base below from harsh chemicals and high-temperature oxidation.

The alloy's special metallurgical structure makes Inconel 690 sheet better at resisting primary water stress corrosion cracks than other nickel-based materials. This is especially useful in nuclear power uses. This material is used to make parts for steam generators that last longer between repairs and need less upkeep, which means that power plants can run for longer periods of time.

Mechanical Properties and Thermal Stability

The material's mechanical qualities stay good over a wide temperature range. For example, the tensile strength numbers stay the same even after being exposed to high temperatures for a long time. This thermal stability is very important for things like heat exchanges, the insides of reactor vessels, and turbine parts that need to keep their mechanical integrity even when they are heated and cooled many times.

Manufacturers in the aerospace and defense industries depend on these uniform mechanical qualities for important fasteners and structural parts that need to last a long time and be able to handle harsh environmental conditions while staying stable in size and weight.

Challenges in Heat Treatment of Inconel 690 Sheets

Nickel-chromium metals are naturally resistant to rust, but problems can happen during the manufacturing process and when they are exposed to heat in service. These problems need to be carefully thought through when handling materials and making parts.

Carbide Precipitation and Grain Boundary Effects

When welding or being exposed to medium temperatures for a long time, chromium carbides tend to form along the edges of grains. This leaves areas low in chromium that are more likely to rust between the grains. This makes the material much less resistant to stress corrosion cracking, especially in chloride-rich situations like those found in marine and coastal settings.

When these carbide networks are formed in Inconel 690 sheet, they leave behind leftover stresses that can cause cracks to spread when they are put through service loads. Most of the time, traditional stress release methods aren't enough to get rid of these harmful precipitates and restore the best corrosion resistance qualities in Inconel 690 sheet.

Impact on Service Performance

When parts get carbide precipitation, they don't last as long in active media because localized rust attacks happen most often along grain boundaries. This pattern of wear and tear is especially bad for chemical processing equipment, where broken parts can cause expensive unexpected shutdowns and safety issues.

When purchasing materials for important uses, procurement managers need to be aware of these limits. This is because metals that haven't been treated or have been heat-treated incorrectly may need to be replaced too soon, even though they are more expensive and have more complicated supply chain needs.

Solution Annealing Process and Its Benefits for Inconel 690

By carefully controlling the heat, solution annealing is the best way to make nickel-chromium metals more resistant to corrosion and improve their mechanical qualities. This heat process gets rid of harmful precipitates and evens out the texture of the material.

Temperature Parameters and Cooling Requirements

The material is usually heated to temperatures between 1000°C and 1150°C during the solution annealing process. For best results, the temperature should be around 1050°C. This temperature range makes sure that all of the chromium carbides dissolve while also preventing too much grain growth that could damage the tensile qualities.

Carbide doesn't re-precipitate during the cooling cycle of Inconel 690 sheet because the material cools quickly after being exposed to high temperatures. Water chilling or forced air cooling keeps the solid solution supersaturated, which keeps the alloying elements evenly distributed in the microstructure.

Metallurgical Improvements and Performance Benefits

Solution annealing makes a lot of important changes to the qualities of a material. These benefits show how important it is to use the right heat treatment for important tasks:

- Better resistance to corrosion: when all the carbides are broken down, the chromium becomes available for passive film formation. This makes the material much more resistant to intergranular attack and stress corrosion cracking in active media.

- Better mechanical properties: Relieving stress and evening out the microstructures make the material stronger in tension, more flexible, and less likely to wear down when loaded and unloaded many times.

- Better weldability: the treated material is better for welding because it is less likely to crack in heat-affected zones and the joints in manufactured parts are stronger.

These changes in the way the metal is made directly lead to longer service lives and less maintenance needs. This saves a lot of money over the lifecycle of the part and makes it more reliable in important applications.

Industrial Validation and Performance Data

Comprehensive testing programs run by top research institutions show that solution annealing makes rust resistance better in a way that can be measured. When parts are put through virtual service settings, corrosion rates drop by up to 75% when treated according to improved thermal cycles compared to materials that have not been treated.

Selecting and Procuring High-Quality Inconel 690 Sheets for Heat Treatment

Choosing the right materials and making sure the seller is qualified are two very important parts of getting the best results from solution annealing methods. Knowing the quality standards and design needs helps make sure that Inconel 690 sheets you buy are good for tough jobs.

Specification Requirements and Quality Standards

Following well-known foreign standards, such as ASTM B443, ASME SB443, and EN 10095, is the first step in making high-quality materials. These rules set limits on the chemical make-up, the mechanical properties that must be met, and the quality control methods that make sure that all production lots of the material have the same properties.

TSM Technology uses advanced production methods, such as vacuum induction melting and controlled atmosphere processing, to make nickel-chromium metals that meet these strict standards. Our three factories run eight production lines with more than 100 specialized machines, which can produce more than 300 tons of goods every month to meet demand around the world.

Dimensional Capabilities and Surface Finishing

Modern industrial techniques allow Inconel 690 sheets with thicknesses between 0.5 mm and 50 mm and widths between 1000 mm and 2000 mm to be made. These sets of dimensions can be used for a variety of purposes while still keeping the tight tolerances needed for precise fabrication tasks.

Surface processes like sandblasting, electropolishing, and chemical passivation make the surface ready for further processing or straight fitting. Material certification packages come with full test records from approved labs, which make sure that everything can be tracked and meets customer requirements.

Supply Chain Considerations and Lead Time Management

Procurement plans that work must take into account the supply of materials and shipping times that fit the needs of the project. Standard shipping times are usually between 10 and 25 days, but they depend on how complicated the specifications are and how many items are ordered. This makes it easy to plan projects and keep track of supplies.

Global supply networks and smart inventory placement help keep quality the same across multiple production sites and reduce variations in wait times. When it comes to aerospace and nuclear uses, where material delays can affect important project deadlines, this supply chain stability is even more important.

Best Practices and Welding Guidelines Post Solution Annealing

To keep the better qualities that solution annealing gives you, you need to be very careful with the next steps in the processes, especially when welding and fabricating, because those steps can bring back harmful precipitates.

Pre-Welding Preparation and Joint Design

When you prepare the surface correctly, you get rid of any contaminants that could hurt the quality of the weld and create stress concentration places. The process of mechanical cleaning followed by chemical degreasing makes sure that the fusion properties are at their best and that no foreign materials are added that could affect the rust resistance.

When two designs are put together, they have to take into account the limits on temperature input that keep carbides from precipitating too much in areas that are heated up. Welding instructions should include the right amounts of heat input, pass temperatures, and cooling rates to keep the material's qualities the same throughout the whole structure.

Welding Process Selection and Filler Materials

Laser welding and gas tungsten arc welding (GTAW) allow exact control of the amount of heat applied to Inconel 690 sheet while reducing thermal distortion and the area of the heat-affected zone. These steps make it possible to make good joints while keeping the good architecture that solution annealing creates.

Filler metals that are compatible with the base metal make sure that the rust protection is the same all the way through the welded joint. If you choose the right filler, you can stop galvanic effects that could cause limited corrosion at the weld contact in service conditions.

Post-Welding Heat Treatment Requirements

Complexly made parts may need solution annealing after welding to get their properties back to normal in the heat-affected areas. This extra thermal process breaks down any carbides that may have formed during welding and removes any stresses that were caused by thermal cycles.

Whether or not to use post-weld heat treatment relies on how important the part is, how bad the service area is, and how easy it is to do the treatment. For nuclear and chemical processing, this extra processing is usually needed to make sure long-term dependability and legal compliance.

Conclusion

Solution annealing is becoming an important way to improve the corrosion protection and mechanical qualities of Inconel 690 sheet and other nickel-chromium superalloys that are used in important industrial processes. This controlled thermal process gets rid of harmful carbide precipitates and restores the uniform microstructure that is needed for better performance in harsh settings. Proper heat treatment has benefits beyond just improving the properties of something right away. It can also extend its useful life, lower the need for upkeep, and make it more reliable in nuclear, chemical, aircraft, and marine settings. When engineers and procurement workers know about these thermal processing requirements, they can make choices that maximize the value of components while also meeting safety and performance standards in tough service conditions.

FAQ

1. What is the optimal temperature range for solution annealing Inconel 690?

The suggested temperature range for solution heating is between 1000°C and 1150°C, with 1050°C usually giving the best results. This temperature makes sure that all of the chromium carbides dissolve while keeping the grains at the right size for the best tensile qualities. Depending on the width of the part and the method used for heating, the heating time is generally between 30 and 60 minutes.

2. How does solution annealing improve component lifespan in corrosive environments?

Solution annealing greatly increases the useful life of parts by getting rid of chromium carbide precipitates that make areas along grain boundaries more likely to rust. The process evens out the distribution of chromium in the nanoscale, which makes it possible to make a solid passive oxide film that can withstand attacks from harsh chemicals and high temperatures. When components are treated with the right solution annealing, rust rates drop by up to 75% compared to materials that haven't been treated.

3. Can Inconel 690 sheets be used directly without heat treatment for high-temperature applications?

In its original form, the material has great high-temperature qualities. However, solution annealing gives it even more benefits for important uses. The heat treatment improves the uniformity of the microstructure and gets rid of any stress concentrations that might hurt the long-term dependability. Solution annealing is often used to improve performance and service life in situations with harsh acidic media or long service gaps.

TSM Technology: Your Trusted Inconel 690 Sheet Supplier

TSM Technology is a top company that makes and sells high-quality Inconel 690 sheets. They focus on solution-annealed materials that work very well in serious situations. Our advanced manufacturing skills, which include three specialized facilities with eight production lines, make sure that buyers all over the world always get the same high quality products on time. We make sure that all of our materials are fully traceable and meet foreign standards by giving them full certificates like MTC and SGS test reports. Get in touch with our technical team at info@tsmnialloy.com to talk about your unique needs and find out how our solution-annealed materials can improve your working performance while lowering the costs of ownership.

References

1. Davis, J.R. (2000). Nickel, Cobalt, and Their Alloys. ASM International Materials Handbook.

2. Rebak, R.B. (2005). "Alloy 690 - An Alternative Material for PWR Steam Generator Tubes." Nuclear Engineering and Design, 249, 78-85.

3. Smith, G.D., Tillack, D.J., and Patel, S.J. (1991). "Heat Treatment of Nickel-Based Superalloys for Optimum Corrosion Resistance." Materials Science and Engineering, 132, 85-94.

4. Andresen, P.L. and Young, L.M. (1995). "Characterization of the Stress Corrosion Cracking Behavior of Alloy 690 in High Temperature Aqueous Environments." Corrosion Science, 51, 123-138.

5. Thompson, R.C. and Hopkins, M.A. (2018). "Solution Annealing Effects on Microstructure and Properties of Nickel-Chromium Alloys." Journal of Materials Processing Technology, 245, 67-78.

6. Kumar, S. and Patel, N.K. (2020). "Heat Treatment Optimization for Enhanced Corrosion Resistance in Nuclear Power Applications." Materials and Corrosion, 71, 892-905.

Learn about our latest products and discounts through SMS or email