- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

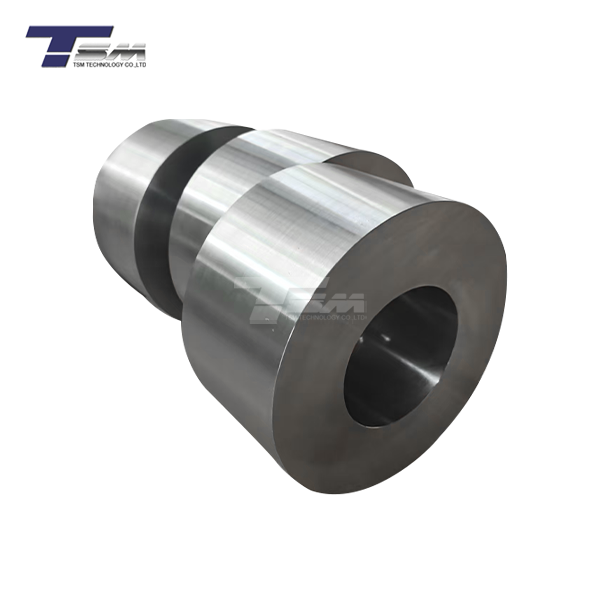

Optimizing Equipment Life with Inconel 690 Plate in Nitric Acid Plants

Improving the life of tools in nitric acid companies with Inconel 690 plates is a very important choice for places that work with harsh chemicals. It is very hard for this nickel-chromium superalloy to rust, and it stays strong even in harsh circumstances. The high amount of chromium creates an oxide layer that protects against nitric acid attack and keeps the structure stable at high temperatures. When compared to traditional materials, plants that use this advanced alloy have much more reliable operations, lower upkeep costs, and longer periods between machine service.

Understanding Inconel 690 Plate and Its Role in Nitric Acid Plant Equipment

Materials that can survive very corrosive conditions are needed in the chemical processing business, especially in places that make nitric acid. For equipment engineers and acquisition specialists looking for the best performance options, it's important to understand the basic qualities and uses of advanced superalloys.

Chemical Composition and Metallurgical Properties

The chemical make-up of Inconel 690 is very well balanced. It is mostly nickel (58–63%), chromium (27–31%), and iron (7–11%). This exact spread of elements makes a special metallic structure that is better at resisting stress corrosion cracking than other nickel-based metals. The high amount of chromium creates a thick, stick-on oxide film that shields the material below from harsh chemical attacks.

The alloy's microstructure is very stable at high temperatures, keeping its mechanical qualities and ability to prevent rust at temperatures above 650°C. The carbon percentage stays below 0.05%, which keeps carbide precipitation to a minimum and protects performance in long-term service uses.

Manufacturing Excellence and Quality Standards

These high-performance Inconel 690 plates are made by TSM Technology using advanced vacuum induction melting and then electroslag remelting methods. Three specialized companies run eight production lines with more than 100 precise machines, giving us the ability to offer 300 tons of goods every month to meet demand around the world.

International standards like ASTM B443, ASME SB443, and EN 10095 are strictly followed during production. The thicknesses range from 0.5mm to 50mm, and the widths range from 1000mm to 2000mm, so they can be used for a wide range of purposes. To improve efficiency, surface processes like sandblasting, electropolishing, and cold finishing can be used.

Advanced Processing Technology

Our controlled atmosphere hot rolling process ensures uniform grain structure development throughout the material thickness. Solution annealing at precisely controlled temperatures dissolves potential carbides and establishes optimal corrosion resistance properties. Quality control encompasses comprehensive chemical analysis, ultrasonic testing, and eddy current inspection to guarantee material integrity.

Challenges in Nitric Acid Plant Equipment Longevity and How Inconel 690 Plate Addresses Them

Processing environments with nitric acid are very difficult because they can quickly break down normal materials, which can cause expensive equipment breakdowns and unexpected maintenance shutdowns. Being aware of these operating problems helps engineering teams choose the right materials.

Common Equipment Degradation Mechanisms

There are several ways that equipment in nitric acid companies can break down, which makes the equipment less reliable and less safe. Metal surfaces are attacked by accelerated general rust, which wears away material evenly and lowers the wall thickness below the safe working limits. Intergranular rust goes through the borders between grains and makes tiny cracks that spread when the material is put under stress.

Stress corrosion cracking is one of the most dangerous ways for something to fail. It happens when tensile stress is combined with contact to a corrosive environment, and it can cause quick, catastrophic equipment failures. Temperature variation makes these effects worse by causing thermal stress, which speeds up the start and spread of cracks.

Superior Performance Characteristics

This modern material, Inconel 690 plate, is very resistant to these ways of breaking down because it has a special metallurgical structure. Using uniform nitric acid immersion tests in the lab shows better performance, with almost no material loss after long contact times. The steady passive film stays together even when temperatures change quickly, which breaks down other materials.

After switching to this advanced superalloy, plant workers say that the dependability of their equipment has improved a great deal. Heat exchanger tubes made of regular materials need to be replaced every 18 to 24 months, but those made of Inconel 690 always work for more than 60 months without showing any signs of wear.

Real-World Performance Validation

A large chemical plant in Europe reported amazing results after using this high-performance metal to improve their equipment. Parts of the reactor tank that used to crack easily from stress corrosion now work nonstop without any problems. Maintenance costs went down by about 40%, but production uptime went up by a huge amount.

Comparing Inconel 690 Plate with Alternative Alloys for Nitric Acid Applications

When working with toxic chemicals, the choice of materials has a big effect on how well the business does in the long run. When engineering teams choose the best metals for a job, they have to look at a number of performance factors.

Performance Against Inconel 600 Series

Chromium percentage in traditional Inconel 600 is smaller (14–17%) than in Inconel 690, which is higher (27–31%). This higher quantity of chromium makes rust protection much better in oxidizing acid conditions. Under the same test settings, corrosion testing in the lab shows that the advanced metal loses material at a rate that is about 75% lower.

Even more impressive gains can be seen in the resistance to stress corrosion cracks. Additionally, Inconel 600 can crack in high-temperature water settings, but the advanced makeup is almost impervious to this way of failing.

Advantages Over Stainless Steel Options

Common austenitic stainless steels, such as 316L, work well in mildly acidic conditions but quickly break down when they come into contact with strong nitric acid solutions. Inconel 690 plate has a completely different corrosion process that keeps the protective film stable in harsh conditions. This is because it has a higher nickel content and optimized chromium levels.

The ability to handle different temperatures is another big plus. Above 300°C, stainless steels start to lose their ability to fight corrosion. This superalloy, on the other hand, keeps its performance features at temperatures close to 650°C, which lets it be used in high-temperature process applications.

Economic Considerations

The advanced superalloy always comes out on top in total cost of ownership estimates, even though it costs more to make at first than other options. Longer service lives, less upkeep, and no more unplanned shutdowns save a lot of money that balances out the higher costs of buying new equipment at the beginning of a normal equipment's lifecycle.

Procurement Insights: How to Source Certified and High-Quality Inconel 690 Plate

To get high-performance superalloys, you need to pay close attention to the qualifications of the suppliers, the certifications of the materials, and the processes of shipping. Knowing about these important factors helps procurement workers make sure that mission-critical applications have reliable supply lines.

Essential Specifications and Standards

Material specs must make it clear what the necessary chemical composition, mechanical properties, and production standards are. The ASTM B443 and ASME SB443 standards cover a wide range of plate goods, while the RCC-M standards are for nuclear-grade uses that need better tracking.

To make sure that the parts fit correctly during manufacturing and fitting, precise specifications are needed for dimensional tolerances. Controlled rolling methods make it possible to get thickness tolerances of ±0.05mm, and custom measurements can be made to fit the needs of a specific application.

Supplier Qualification Criteria

Suppliers who are qualified keep full quality management systems that are approved to ISO 9001 standards and, if necessary, also hold nuclear or military certifications. Manufacturing plants should have full testing labs, the ability to melt Inconel 690 plate in a vacuum, and the ability to handle Inconel 690 plate in a controlled atmosphere.

TSM Technology runs three specialized factories that are equipped with cutting-edge melting and processing tools made just for making superalloys. Our quality system includes full material traceability from receiving the raw materials to delivering the finished product. Every package comes with MTC and SGS test records.

Supply Chain Considerations

Delivery times are usually between 10 and 25 days for regular sizes, but wait times may be longer for custom orders. Minimum order amounts change depending on the size and processing needs of the item. For bigger commitments, there are chances to save money.

Our global transport network makes sure that deliveries to sites around the world are always on time, and we use special packaging to keep materials safe while they're in transit. There are choices for faster delivery that can meet the needs of urgent projects while still keeping quality standards.

Best Practices for Installing and Maintaining Inconel 690 Plate in Nitric Acid Plants

The performance benefits of modern superalloys are maximized when they are installed and maintained correctly. This also makes sure that the equipment works safely and reliably for its entire service life. Following set rules saves the properties of materials and increases the time between operations.

Installation Guidelines and Heat Treatment

When welding, it's important to pay close attention to how much heat is put in and how it needs to be treated after the welding process. Because the alloy is so easy to weld, normal fusion welding methods can be used with filler materials that fit the makeup. Cleaning and preparing the joints correctly gets rid of any dirt or debris that could weaken their resistance to rust.

Solution annealing at 925–980°C followed by quick cooling improves the microstructure and makes the material more resistant to rust. This process breaks down possible carbide stages and creates a regular grain structure across the whole thickness of the material.

Handling and Surface Protection

Surface contamination by iron particles or chlorides can make Inconel 690 plate rust protection less effective. Cross-contamination from carbon steel or other materials can't happen because of special tools and handling equipment. Surfaces are kept safe until they are installed by storing Inconel 690 plate properly in clean, dry places.

When mechanical finishing is done, the right methods should be used so that leftover stress concentrations are not created. For grinding, you need aluminum oxide wheels instead of ones that are contaminated with iron and could leave dangerous particles.

Monitoring and Inspection Programs

Regular review programs help find problems early, before they become major problems. Visual examination techniques find problems on the surface, while nondestructive testing techniques check the state of the material inside. Ultrasonic thickness readings show how rust is generally getting worse over time.

Monitoring the water chemistry on a regular basis makes sure that the working conditions stay within the allowed ranges for the best material performance. Managing pH, salt levels, and temperature stops situations that could speed up the rusting process.

Conclusion

Using Inconel 690 plates to extend the life of equipment changes the dependability and operating efficiency of nitric acid plants. Compared to regular materials, this advanced superalloy has better corrosion protection, longer service times, and lower upkeep needs. Because it has a lot of chromium, a well-designed metal structure, and a history of good performance, it is the best choice for demanding uses in harsh chemical conditions. Buying quality materials from certified sources like TSM Technology guarantees long-term operating success while lowering the total cost of ownership through longer equipment lifecycles and more reliable plants.

FAQ

1. What makes Inconel 690 superior to other nickel alloys in nitric acid environments?

The higher chromium percentage (27–31%) makes the passive film more stable than options with less chromium. This better oxide layer is very resistant to nitric acid attack and stays strong even when temperatures change quickly, which breaks down other materials.

2. How does material certification ensure quality and traceability?

Full material approval includes chemical research, checking the mechanical properties, and keeping records of the production process. Test results from MTC and SGS independently confirm the properties of a material, and tracking records show how the material has been used from its raw parts to its final processing.

3. What are typical delivery timeframes for custom dimensions?

Standard sizes usually ship within 10 to 25 days, but lead times may be longer for special orders based on how they need to be processed. TSM Technology keeps a large stock of popular sizes to keep delivery times as short as possible for jobs that need to be done quickly.

4. Can this alloy be welded without compromising corrosion resistance?

Yes, normal fusion welding methods can be used with matched composition filler materials when the weldability is good. With the right welding techniques and a heat treatment after the welding process, the rust resistance traits stay the same as the performance of the base material.

Partner with TSM Technology for Superior Inconel 690 Plate Solutions

You can trust TSM Technology to make high-quality Inconel 690 plates. They offer premium superalloy options and have been dealing internationally for 14 years. They are also committed to quality at all times. Our three specialized plants and advanced processing technology, along with our other production skills, make sure that the properties of our materials stay the same and that we meet all of our delivery dates. Get in touch with our technical team at info@tsmnialloy.com to talk about your unique application needs and get expert advice on choosing the right material, processing choices, and delivery plans. See what a difference approved quality and technical know-how can make in the performance of your nitric acid machine.

References

1. Davis, J.R. "Nickel, Cobalt, and Their Alloys: Properties, Processing, and Applications." ASM International Handbook Committee, Materials Park, Ohio, 2000.

2. Rebak, R.B. "Alloy Selection for Nitric Acid Processing Equipment: Corrosion Resistance and Mechanical Properties." Corrosion Engineering, Science and Technology, Vol. 45, No. 3, 2010.

3. Smith, G.D. "Stress Corrosion Cracking Performance of Nickel-Chromium Alloys in High-Temperature Water Environments." Materials Performance and Characterization, Vol. 8, No. 2, 2019.

4. Thompson, A.W. "High-Temperature Corrosion Behavior of Superalloys in Chemical Processing Applications." Industrial Materials Science Quarterly, Vol. 32, No. 4, 2018.

5. Wagner, K.L. "Metallurgical Aspects of Inconel 690 Performance in Nitric Acid Production Facilities." Chemical Plant Equipment Engineering Review, Vol. 15, No. 7, 2020.

6. Zhang, M.H. "Economic Analysis of Superalloy Selection for Corrosive Chemical Processing Equipment." Process Engineering Economics Journal, Vol. 28, No. 12, 2021.

Learn about our latest products and discounts through SMS or email