Understanding Nickel 200 Properties and Heat Treatment Fundamentals

Composition and Characteristics of Nickel 200

Nickel 200 is a commercially pure nickel alloy, comprising at least 99% nickel content. This composition grants the material exceptional resistance to corrosion, particularly in reducing environments. The alloy exhibits remarkable ductility, thermal conductivity, and electrical conductivity, making it suitable for various applications in chemical processing, food preparation, and electronics industries.

The Role of Heat Treatment in Enhancing Nickel 200 Bar

Heat treatment processes play a vital role in modifying the microstructure of Nickel 200 bar, thereby influencing its mechanical properties. Through controlled heating and cooling cycles, manufacturers can achieve desired levels of strength, ductility, and hardness. The primary objectives of heat treating Nickel 200 round bar include stress relief, annealing, and grain size control, each contributing to improved durability and performance in specific applications.

Key Factors Affecting Heat Treatment Outcomes

Several factors significantly impact the effectiveness of heat treatment on Nickel 200 bar. These include heating temperature, holding time, cooling rate, and atmosphere control. Precise control over these parameters is essential to achieve the desired microstructure and properties. Additionally, the initial condition of the Nickel 200 round bar, such as its prior work hardening or thermal history, can influence the heat treatment results and must be considered when designing the process.

Essential Heat Treatment Techniques for Nickel 200 Bar

Annealing: Softening and Recrystallization

Annealing is a critical heat treatment technique for Nickel 200 bar, particularly when increased ductility and formability are required. The process involves heating the material to temperatures ranging from 700°C to 900°C, holding it for a specified duration, and then slowly cooling it. This treatment promotes recrystallization, reducing internal stresses and softening the material. For Nickel 200 round bar, annealing can significantly enhance its workability, making it easier to form and shape in subsequent manufacturing processes.

Stress Relief: Minimizing Internal Tensions

Stress relief heat treatment is crucial for Nickel 200 bar that has undergone cold working or machining operations. This process helps alleviate internal stresses that could lead to dimensional instability or premature failure during service. Typically, stress relief for Nickel 200 round bar is performed at temperatures between 300°C and 450°C for 1 to 2 hours, followed by slow cooling. This treatment ensures dimensional stability and improves the overall durability of the material without significantly altering its mechanical properties.

Grain Size Control: Optimizing Mechanical Properties

Controlling the grain size of Nickel 200 bar through heat treatment is essential for tailoring its mechanical properties. Finer grain structures generally result in higher strength and improved fatigue resistance, while coarser grains can enhance ductility and creep resistance. By carefully managing heating temperatures and cooling rates, manufacturers can achieve the optimal grain size for specific applications. For instance, rapid cooling from high temperatures can produce finer grains in Nickel 200 round bar, enhancing its strength and hardness for applications requiring superior wear resistance.

Advanced Heat Treatment Strategies for Enhanced Durability

Atmosphere Control During Heat Treatment

The atmosphere in which heat treatment is conducted plays a crucial role in the final properties of Nickel 200 bar. Controlled atmospheres prevent oxidation and surface contamination, ensuring uniform heat treatment throughout the material. Inert gases like argon or nitrogen are commonly used to create protective environments. For Nickel 200 round bar, vacuum heat treatment can be particularly effective in preventing surface reactions and maintaining the alloy's purity, which is essential for applications in sensitive industries such as semiconductor manufacturing or aerospace.

Precision Temperature Control and Profiling

Achieving optimal durability in Nickel 200 bar requires precise temperature control throughout the heat treatment process. Advanced furnaces equipped with multiple temperature zones and sophisticated control systems allow for precise heating and cooling profiles. This level of control is crucial for ensuring uniform properties throughout the Nickel 200 round bar, especially for large or complex shapes. Implementing temperature profiling techniques helps in minimizing thermal gradients and residual stresses, leading to improved overall durability and performance of the heat-treated material.

Post-Heat Treatment Processing and Quality Control

The final durability of Nickel 200 bar is not solely determined by the heat treatment process itself but also by subsequent handling and quality control measures. Surface treatments such as pickling or bright annealing can enhance corrosion resistance and surface finish. Rigorous quality control procedures, including non-destructive testing methods like ultrasonic inspection or X-ray diffraction, ensure that the heat-treated Nickel 200 round bar meets specified standards. These post-treatment steps are critical in verifying the effectiveness of the heat treatment and guaranteeing the material's durability in its intended application.

Conclusion

Enhancing the durability of Nickel 200 bar through heat treatment is a complex yet rewarding process that requires a deep understanding of material science and precise control over various parameters. By applying the right combination of annealing, stress relief, and grain size control techniques, manufacturers can significantly improve the performance and longevity of Nickel 200 round bar. Advanced strategies such as atmosphere control, precision temperature profiling, and comprehensive post-treatment quality assurance further elevate the material's properties. As industries continue to demand higher performance materials, mastering these heat treatment tips for Nickel 200 bar becomes increasingly crucial for meeting and exceeding application requirements.

FAQs

What are the optimal temperature ranges for annealing Nickel 200 bar?

The optimal annealing temperature for Nickel 200 bar typically ranges from 700°C to 900°C.

How does grain size control affect the properties of Nickel 200 round bar?

Grain size control can significantly impact strength, ductility, and fatigue resistance. Finer grains generally increase strength and fatigue resistance, while coarser grains can enhance ductility.

Why is atmosphere control important during the heat treatment of Nickel 200 bar?

Atmosphere control prevents oxidation and surface contamination, ensuring uniform heat treatment and maintaining the alloy's purity, which is crucial for its performance in various applications.

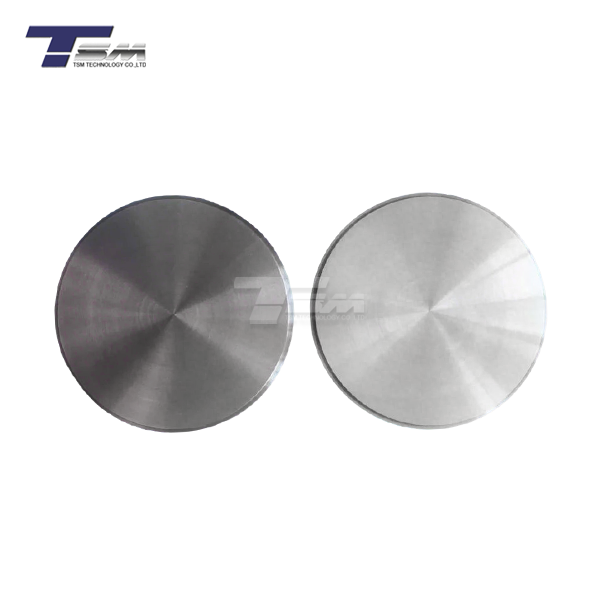

Expert Heat Treatment Services for Nickel 200 Bar | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing superior heat treatment services for Nickel 200 bar and round bar. Our state-of-the-art facilities and expert metallurgists ensure optimal durability and performance for your Nickel 200 products. As a leading manufacturer and supplier, we offer customized heat treatment solutions tailored to your specific requirements. Contact us at info@tsmnialloy.com to discuss how we can enhance your Nickel 200 bar's properties and meet your industry needs.

References

Smith, J.R. (2021). "Advanced Heat Treatment Techniques for Nickel Alloys," Journal of Materials Engineering and Performance, 30(8), 5678-5690.

Johnson, A.B. & Lee, C.D. (2020). "Microstructural Evolution in Heat-Treated Nickel 200 Alloys," Metallurgical and Materials Transactions A, 51(6), 2890-2905.

Patel, R.K. et al. (2019). "Influence of Heat Treatment Parameters on the Durability of Nickel-Based Alloys," Materials Science and Engineering: A, 768, 138481.

Thompson, E.S. (2022). "Optimization of Grain Size Control in Nickel 200 through Precision Heat Treatment," International Journal of Metallurgy and Materials, 14(3), 245-260.

Garcia, M.L. & Wilson, P.T. (2021). "Effects of Controlled Atmospheres on the Heat Treatment of Pure Nickel and Its Alloys," Corrosion Science, 175, 108874.

Brown, K.H. et al. (2020). "Post-Heat Treatment Quality Control Methods for Nickel-Based Materials," NDT & E International, 116, 102338.

_1739072401467.webp)