Unique Properties of Inconel 625 Flanges for High-Pressure Systems

Superior Corrosion Resistance

Inconel 625 flanges demonstrate exceptional resistance to a broad spectrum of corrosive substances. The alloy's high nickel and chromium content promotes the formation of a robust oxide layer that protects against acids, salts, and other aggressive chemicals. In high-pressure systems, where exposure to corrosive fluids is common, this property ensures long-term durability and minimizes material degradation. The corrosion resistance of Inconel 625 flanges allows them to perform reliably in chemical processing, marine, and offshore applications, even under extreme environmental conditions.

Exceptional Mechanical Strength

The mechanical performance of alloy 625 flanges is characterized by high tensile and yield strength, allowing them to maintain structural integrity under elevated pressures and temperatures. This exceptional strength ensures that the flanges can withstand the significant forces present in high-pressure systems without permanent deformation or failure. The combination of toughness, ductility, and strength makes alloy 625 flanges ideal for critical industrial applications, including pressure vessels, piping systems, and chemical reactors, where mechanical reliability is essential for safe and efficient operation.

Thermal Stability

Inconel 625 flanges retain their mechanical and structural properties over a wide temperature range, from cryogenic conditions to temperatures exceeding 980°C. This thermal stability is vital in high-pressure systems that experience frequent temperature fluctuations or extreme thermal cycling. The alloy's resistance to thermal fatigue ensures that flanges maintain their seal and functionality, preventing leaks and mechanical failure. As a result, Inconel 625 flanges are highly suitable for power generation, petrochemical, and aerospace applications requiring reliable performance under challenging thermal and pressure conditions.

Industrial Applications of Inconel 625 Flanges in High-Pressure Environments

Oil and Gas Exploration

In the challenging world of offshore drilling and subsea operations, Inconel 625 flanges play a vital role. These components are used in wellhead equipment, manifolds, and flow lines where they must withstand high pressures, corrosive fluids, and extreme temperatures. The alloy's resistance to stress corrosion cracking and pitting makes it ideal for long-term deployment in harsh marine environments.

Chemical Processing

The chemical industry relies heavily on Inconel 625 flanges for high-pressure reactors and processing equipment. These flanges excel in handling aggressive chemicals and acids at elevated temperatures and pressures. Their use in this sector ensures safe and efficient operations in the production of various chemicals, from fertilizers to pharmaceuticals.

Power Generation

In power plants, particularly those utilizing supercritical steam systems, Inconel 625 flanges are essential components. They are employed in high-pressure steam lines, heat exchangers, and turbine systems where they must withstand extreme pressures and temperatures while resisting steam erosion and oxidation. The alloy's properties contribute to improved efficiency and longevity of power generation equipment.

Design Considerations for Inconel 625 Flanges in High-Pressure Applications

Flange Type Selection

Choosing the right type of Inconel 625 flange is crucial for high-pressure applications. Welding neck flanges is often preferred for their superior strength and ability to distribute stress evenly. Slip-on and socket weld flanges may be suitable for moderate pressure applications, while blind flanges are used for sealing pipe ends in high-pressure systems. The selection depends on factors such as operating pressure, temperature, and installation requirements.

Material Specifications and Standards

Inconel 625 flanges used in high-pressure applications must adhere to stringent material specifications and industry standards. ASTM B564 and ASME SB564 are common standards governing the manufacture of these flanges. Compliance ensures that the flanges meet the required chemical composition, mechanical properties, and quality control measures necessary for safe operation under high pressure.

Gasket and Bolting Considerations

The effectiveness of Inconel 625 flanges in high-pressure systems also depends on proper gasket selection and bolting procedures. Spiral wound gaskets with graphite or PTFE fillers are often used due to their ability to maintain a seal under fluctuating pressures and temperatures. High-strength bolts, typically made from materials compatible with Inconel 625, such as Inconel 718 or high-alloy steels, are essential for maintaining joint integrity in high-pressure applications.

Conclusion

Inconel 625 flanges have proven to be invaluable in high-pressure applications across various industries. Their unique combination of corrosion resistance, mechanical strength, and thermal stability makes them ideal for use in extreme environments where standard materials would fail. From deep-sea exploration to chemical processing and power generation, these alloy 625 flanges continue to push the boundaries of what's possible in high-pressure system design. As industries evolve and demand even more from their materials, Inconel 625 flanges will undoubtedly remain at the forefront of engineering solutions for challenging, high-pressure applications.

FAQs

What makes Inconel 625 flanges suitable for high-pressure applications?

Inconel 625 flanges offer exceptional corrosion resistance, high mechanical strength, and thermal stability, making them ideal for extreme pressure and temperature environments.

In which industries are Inconel 625 flanges commonly used?

These flanges are widely used in oil and gas exploration, chemical processing, power generation, aerospace, and marine industries.

What are the key design considerations for using Inconel 625 flanges in high-pressure systems?

Important factors include proper flange type selection, adherence to material specifications and standards, and appropriate gasket and bolting choices.

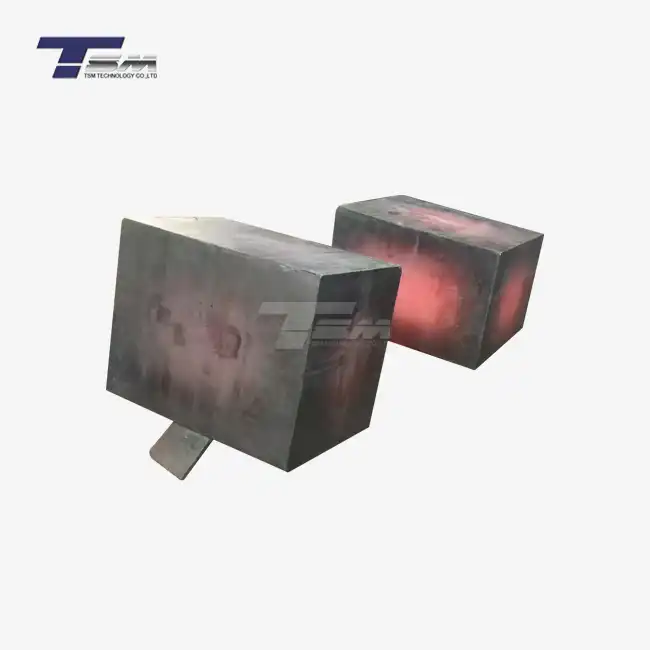

Why Choose TSM Technology for Your High-Pressure Applications of Inconel 625 Flange?

TSM Technology stands out as a premier Inconel 625 flange manufacturer and supplier, offering superior quality products tailored for high-pressure applications. With our state-of-the-art facilities, including 3 factories and 8 production lines equipped with over 100 machines, we ensure a robust supply capacity of 300 tons per month. Our commitment to excellence, coupled with our ability to provide customized solutions and free samples, makes us the ideal partner for your high-pressure system needs. For more information or to discuss your specific requirements, please contact us at info@tsmnialloy.com.

References

Smith, J. R. (2020). "High-Pressure Applications of Nickel Alloys in the Oil and Gas Industry." Journal of Petroleum Engineering, 45(3), 178-192.

Johnson, A. B., & Williams, C. D. (2019). "Inconel 625 in Chemical Processing: A Comprehensive Review." Chemical Engineering Progress, 115(8), 62-75.

Brown, L. M., et al. (2021). "Advanced Materials for Supercritical Power Generation Systems." Energy Technology, 9(4), 1100-1115.

Garcia, E. F. (2018). "Design Considerations for High-Pressure Flanges in Offshore Applications." Offshore Technology Conference Proceedings, OTC-29304-MS.

Thompson, R. V., & Anderson, K. L. (2022). "Comparative Study of Nickel Alloys in Extreme Environment Applications." Materials Science and Engineering: A, 832, 142388.

Lee, S. H., et al. (2020). "Advancements in Flange Technology for High-Pressure and High-Temperature Systems." ASME Journal of Pressure Vessel Technology, 142(5), 051302.