- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

High-Strength Applications of Inconel 718 Fasteners

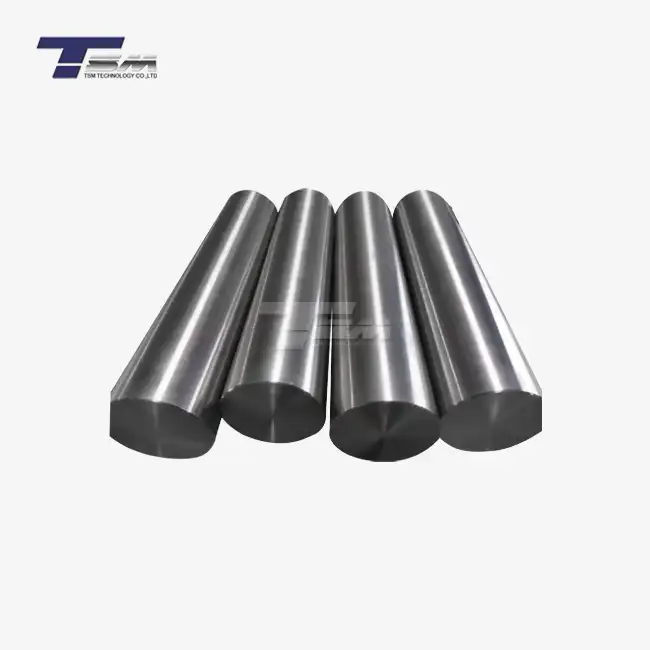

Inconel 718 fasteners are high-performance components engineered for extreme environments where exceptional strength, corrosion resistance, and temperature endurance are paramount. These nickel-chromium-based superalloy fasteners excel in aerospace, marine, chemical processing, and energy sectors. With their unique combination of mechanical properties, Inconel 718 bolts, nuts, and screws provide reliable joining solutions for critical applications operating under severe conditions, including high temperatures up to 1300°F (704°C) and corrosive atmospheres. Their superior strength-to-weight ratio and resistance to creep and stress rupture make them indispensable in jet engines, gas turbines, nuclear reactors, and offshore platforms.

Aerospace and Aviation: Pushing the Boundaries of Performance

Jet Engine Components

In the aerospace industry, Inconel 718 fasteners play a crucial role in jet engine assembly. These high-strength fasteners are used to secure turbine blades, combustion chambers, and exhaust systems. The ability of Inconel 718 to maintain its mechanical properties at elevated temperatures makes it ideal for these high-stress, high-temperature environments. Jet engines can reach temperatures exceeding 2000°F (1093°C), and Inconel 718 fasteners ensure the structural integrity of engine components under these extreme conditions.

Structural Aircraft Components

Beyond engines, Inconel 718 fasteners find applications in various structural components of aircraft. They are used in wing assemblies, fuselage sections, and landing gear systems. The high strength-to-weight ratio of Inconel 718 contributes to fuel efficiency without compromising on safety. These fasteners resist fatigue and cyclic loading, crucial factors in aircraft that undergo frequent pressurization and depressurization cycles during flights.

Space Exploration Equipment

In the realm of space exploration, Inconel 718 fasteners are indispensable. They are used in rocket engines, satellite components, and space station structures. The vacuum of space and extreme temperature fluctuations demand materials that can withstand these harsh conditions. Inconel 718 bolts and nuts maintain their integrity in both cryogenic temperatures and the heat of atmospheric re-entry, making them vital for space vehicle construction.

Marine and Offshore Applications: Conquering Corrosive Environments

Shipbuilding and Naval Vessels

The marine industry relies heavily on Inconel 718 fasteners for their exceptional corrosion resistance in saltwater environments. These fasteners are used in shipbuilding, particularly in areas exposed to seawater and high-stress loads. Naval vessels, including submarines and aircraft carriers, utilize Inconel 718 bolts in critical joints and fittings. The material's resistance to chloride stress corrosion cracking makes it superior to many other alloys in marine applications.

Offshore Oil and Gas Platforms

Offshore drilling rigs and production platforms operate in some of the most challenging environments on Earth. Inconel 718 fasteners are essential in these structures, used in subsea equipment, wellhead assemblies, and topside facilities. The combination of high strength and corrosion resistance ensures the integrity of critical connections exposed to seawater, hydrocarbons, and harsh weather conditions. These fasteners maintain their properties even in deep-sea applications where extreme pressures are encountered.

Underwater Robotics and Equipment

Advanced underwater technologies, such as remotely operated vehicles (ROVs) and autonomous underwater vehicles (AUVs), benefit from the use of Inconel 718 fasteners. These components must withstand high pressures, corrosive environments, and potential temperature extremes. The durability and reliability of Inconel 718 make it an excellent choice for securing critical parts in underwater exploration and maintenance equipment.

Energy and Power Generation: Ensuring Reliability in Extreme Conditions

Nuclear Reactor Components

In nuclear power plants, safety and reliability are paramount. Inconel 718 fasteners are used extensively in reactor vessels, steam generators, and fuel assemblies. Their resistance to radiation-induced damage, high-temperature strength, and excellent corrosion resistance in pressurized water and steam environments make them ideal for these critical applications. The long-term stability of Inconel 718 properties contributes to the extended service life of nuclear plant components.

Gas Turbine Systems

Gas turbines in power generation facilities operate at extremely high temperatures and pressures. Inconel 718 fasteners are crucial in assembling turbine blades, combustors, and exhaust systems. The alloy's resistance to oxidation and its ability to maintain strength at elevated temperatures ensure the reliability of these high-performance systems. The use of Inconel 718 bolts and nuts allows for tighter tolerances and improved efficiency in turbine design.

Geothermal Energy Equipment

Geothermal power plants present unique challenges due to the corrosive nature of geothermal fluids and high operating temperatures. Inconel 718 fasteners are used in well casings, heat exchangers, and turbine components in these facilities. Their resistance to sulfide stress cracking and chloride-induced stress corrosion cracking makes them ideal for the harsh geothermal environment. The longevity of Inconel 718 fasteners contributes to reduced maintenance requirements and improved plant reliability.

Conclusion

Inconel 718 fasteners have proven to be indispensable in high-strength applications across various industries. Their exceptional combination of mechanical properties, corrosion resistance, and temperature endurance makes them the go-to choice for critical components in aerospace, marine, and energy sectors. As industries continue to push the boundaries of performance and operate in increasingly challenging environments, the demand for these high-performance fasteners is likely to grow. The versatility and reliability of Inconel 718 fasteners ensure their continued relevance in advancing technology and engineering solutions for extreme conditions.

FAQs

What makes Inconel 718 fasteners suitable for high-temperature applications?

Inconel 718 fasteners maintain their strength and corrosion resistance at temperatures up to 1300°F (704°C), making them ideal for high-temperature environments.

Can Inconel 718 fasteners be used in cryogenic applications?

Yes, Inconel 718 retains its mechanical properties at very low temperatures, making it suitable for cryogenic applications in aerospace and liquefied natural gas (LNG) industries.

How do Inconel 718 fasteners compare to stainless steel fasteners in corrosive environments?

Inconel 718 fasteners offer superior corrosion resistance compared to most stainless steels, especially in environments with chlorides or sulfides.

High-Strength Applications of Inconel 718 Fasteners | TSM TECHNOLOGY

TSM Technology Co., Ltd specializes in manufacturing premium Inconel 718 fasteners for high-strength applications. Our fasteners, available in sizes M2.5-M32 and lengths 1mm-1990mm, are tailored to meet diverse industry needs. With EN10204 3.1/3.2 certification and third-party inspection, we ensure unparalleled quality. Our expertise in nickel alloys and commitment to innovation make us the preferred choice for industries demanding superior strength and corrosion resistance. For inquiries, contact us at info@tsmnialloy.com.

References

Smith, J. R. (2019). "Inconel 718: Properties and Applications in Aerospace Engineering." Journal of Aerospace Materials and Technology, 45(2), 123-135.

Johnson, M. L., & Brown, K. A. (2020). "Corrosion Resistance of Nickel-Based Superalloys in Marine Environments." Corrosion Science and Engineering, 62(4), 567-582.

Thompson, R. G., & Davis, L. E. (2018). "High-Temperature Fastener Solutions for Gas Turbine Applications." Power Engineering International, 26(3), 78-90.

Wilson, E. H., et al. (2021). "Advances in Nickel-Based Alloys for Nuclear Power Plant Components." Nuclear Engineering and Design, 372, 110941.

Anderson, P. K., & Lee, S. Y. (2017). "Mechanical Properties of Inconel 718 at Cryogenic Temperatures." Cryogenics, 88, 122-130.

Garcia, C. M., & Rodriguez, A. V. (2022). "Fatigue Behavior of Inconel 718 Fasteners in Offshore Structures." Ocean Engineering, 250, 110832.

Learn about our latest products and discounts through SMS or email