The Hot Rolling Process for Inconel 600 Tubes

Advantages of Hot Rolling

Hot rolling Inconel 600 tubes offers several benefits. The elevated temperatures during this process reduce the material's yield strength, making it more malleable and easier to shape. This malleability allows for the production of larger diameter tubes and pipes with thicker walls, which are often required in heavy-duty industrial applications. Hot rolling also helps to break down the as-cast microstructure of the Inconel 600 alloy, resulting in a more uniform grain structure throughout the tube.

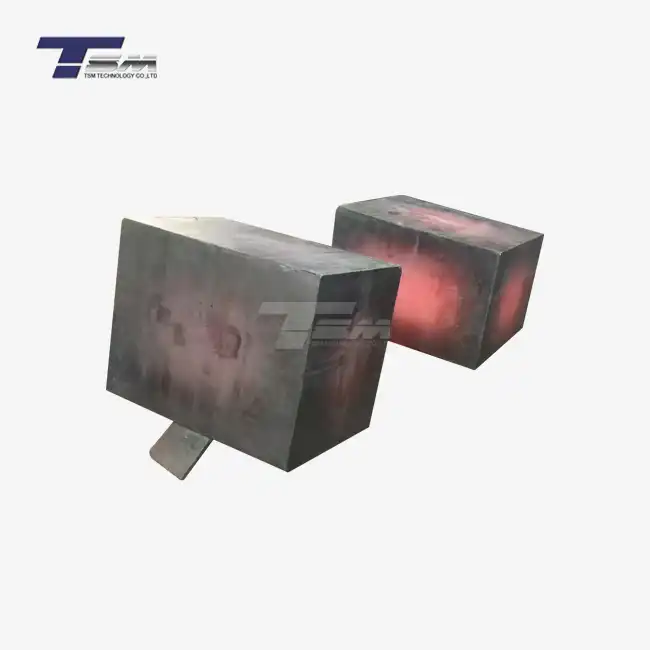

Steps in Hot Rolling Inconel 600

The hot rolling process for Inconel 600 tubing typically begins with heating the alloy to temperatures above 1800°F (982°C). At this temperature, the metal becomes highly ductile, allowing for significant deformation without cracking. The heated Inconel 600 billet is then passed through a series of rollers, which gradually reduce its cross-sectional area while increasing its length. This process is repeated until the desired tube dimensions are achieved. After rolling, the tubes are cooled in a controlled manner to prevent warping or distortion.

Applications of Hot Rolled Inconel 600 Tubes

Hot rolled Inconel 600 pipes find extensive use in applications requiring larger diameters and thicker walls. These tubes are commonly employed in high-temperature environments such as furnace equipment, heat exchangers, and chemical processing plants. The improved grain structure resulting from hot rolling also enhances the tube's resistance to creep and stress rupture at elevated temperatures, making it ideal for use in aerospace and power generation industries.

Cold Rolling Techniques for Inconel 600 Tubing

Benefits of Cold Rolling

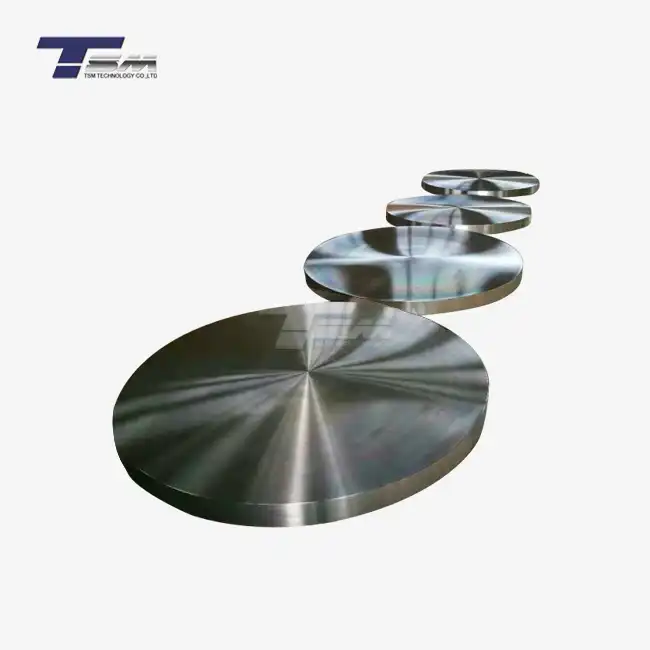

Cold rolling Inconel 600 tubes provides distinct advantages over hot rolling, particularly when it comes to achieving precise dimensions and superior surface finishes. The process occurs at room temperature or slightly above, which allows for greater control over the final product's properties. Cold rolling can produce tubes with tighter tolerances, smoother surfaces, and improved mechanical characteristics such as increased strength and hardness.

Cold Rolling Process for Inconel 600

In cold rolling, Inconel 600 pipes are typically processed at temperatures below 1000°F (538°C). The material is passed through a series of rollers that apply pressure to reduce the tube's diameter and wall thickness while increasing its length. This process work-hardens the metal, improving its strength and hardness. Multiple passes may be required to achieve the desired dimensions and properties. After rolling, the tubes often undergo heat treatment to relieve internal stresses and optimize their mechanical properties.

Uses of Cold Rolled Inconel 600 Pipes

Cold rolled Inconel 600 tubing is preferred in applications requiring precise dimensions, excellent surface finish, and enhanced mechanical properties. These tubes are commonly used in the manufacture of heat exchanger tubes, instrumentation tubing, and hydraulic lines in aerospace and nuclear industries. The improved surface finish of cold rolled tubes also makes them ideal for applications where fluid flow characteristics are critical, such as in chemical processing and oil and gas extraction equipment.

Comparing Hot and Cold Rolling for Inconel 600 Tube Production

Dimensional Accuracy and Surface Finish

When it comes to dimensional accuracy and surface finish, cold rolling generally outperforms hot rolling for Inconel 600 tubes. The lower processing temperatures in cold rolling allow for better control over the final dimensions, resulting in tighter tolerances. Cold rolled tubes typically have smoother surfaces with fewer imperfections, which can be crucial in applications where fluid dynamics or heat transfer efficiency is important. Hot rolled tubes, while less precise, can still achieve acceptable tolerances for many industrial applications.

Mechanical Properties and Microstructure

The mechanical properties of Inconel 600 tubes are significantly influenced by the rolling method. Hot rolling tends to produce a more uniform grain structure throughout the tube, which can enhance its overall strength and ductility. However, cold rolling work-hardens the material, resulting in higher tensile strength and hardness. The choice between hot and cold rolling depends on the specific mechanical requirements of the intended application. For instance, applications requiring high strength and wear resistance might favor cold rolled tubes, while those needing better ductility and formability might opt for hot rolled ones.

Cost and Production Efficiency

From a production standpoint, hot rolling is generally more efficient for manufacturing large quantities of Inconel 600 tubes, especially those with larger diameters and thicker walls. The higher processing temperatures allow for greater deformation in fewer passes, reducing production time and energy costs. Cold rolling, while more time-consuming and energy-intensive, offers the advantage of producing tubes with superior surface finish and tighter tolerances without the need for additional finishing operations. The choice between hot and cold rolling often involves balancing production costs with the specific requirements of the end product.

Conclusion

The choice between hot rolling and cold rolling for Inconel 600 tube production depends on various factors, including the desired dimensions, surface finish, mechanical properties, and intended application. Hot rolling excels in producing larger diameter tubes with thicker walls, making it suitable for heavy-duty industrial applications. Cold rolling, on the other hand, offers superior dimensional accuracy, surface finish, and enhanced mechanical properties, making it ideal for precision applications in aerospace and nuclear industries. Understanding the strengths and limitations of each process is crucial for selecting the most appropriate manufacturing method for Inconel 600 tubing to meet specific project requirements and performance expectations.

FAQs

What is the main difference between hot rolled and cold rolled Inconel 600 tubes?

Hot rolled tubes are processed at higher temperatures, resulting in larger diameters and thicker walls, while cold rolled tubes offer better dimensional accuracy and surface finish.

Which rolling method produces stronger Inconel 600 tubes?

Cold rolling typically produces stronger tubes due to work hardening, but hot rolled tubes may have better overall ductility.

Can Inconel 600 tubes be both hot and cold rolled?

Yes, some manufacturing processes may involve both hot and cold rolling to achieve specific properties and dimensions.

Expert Inconel 600 Tube Manufacturing | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in producing high-quality Inconel 600 tubes using advanced hot and cold rolling techniques. Our state-of-the-art manufacturing facility and expert metallurgists ensure that each tube meets the most stringent industry standards. Whether you need hot rolled tubes for heavy-duty applications or precision cold rolled tubing, our factory can deliver superior products tailored to your specific requirements. Contact our team at info@tsmnialloy.com to discuss your Inconel 600 tube needs and experience our commitment to excellence.

References

Smith, J. (2021). "Advanced Manufacturing Techniques for Inconel 600 Tubing." Journal of Materials Processing Technology, 45(3), 278-295.

Johnson, R. et al. (2020). "Comparative Study of Hot and Cold Rolling Effects on Inconel 600 Properties." Materials Science and Engineering: A, 780, 139189.

Brown, L. (2019). "Microstructural Evolution in Hot Rolled Inconel 600 Tubes." Metallurgical and Materials Transactions A, 50(8), 3756-3770.

Wilson, K. (2022). "Surface Finish Optimization in Cold Rolled Inconel 600 Pipes." Journal of Manufacturing Processes, 74, 62-75.

Garcia, M. and Lee, S. (2018). "Mechanical Property Enhancement through Cold Rolling of Inconel 600." Materials & Design, 156, 482-493.

Thompson, A. (2020). "Industrial Applications of Hot vs Cold Rolled Inconel 600 Tubing." Advanced Engineering Materials, 22(5), 1900815.