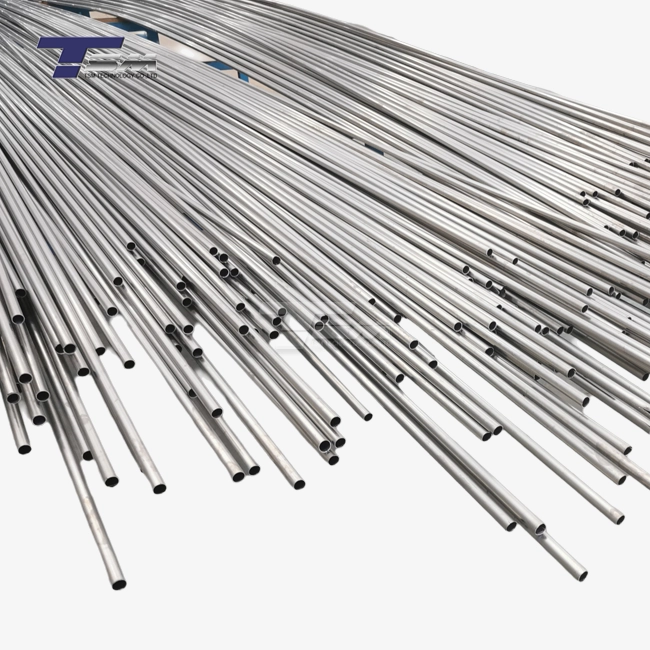

Advanced Cutting Techniques for Incoloy 825 Tubes

Abrasive Wheel Cutting: Precision and Versatility

Abrasive wheel cutting is a widely used method for Incoloy 825 tube fabrication. This technique employs a high-speed rotating wheel coated with abrasive particles to slice through the material. The process offers several advantages, including minimal heat generation, which helps preserve the tube's microstructure. When cutting Incoloy 825 pipes, it's essential to select the appropriate wheel composition and grit size to achieve clean, burr-free cuts. Operators must also consider factors such as cutting speed and coolant application to optimize results and extend wheel life.

Plasma Cutting: Speed and Efficiency

Plasma cutting is another effective method for processing Incoloy 825 tubes, particularly for thicker-walled pipes. This technique utilizes a high-temperature plasma arc to melt and expel material, resulting in rapid and precise cuts. When employing plasma cutting for Incoloy 825, it's crucial to adjust parameters such as arc voltage, cutting speed, and gas flow rate to achieve optimal cut quality. The process excels in creating complex shapes and contours, making it suitable for custom fabrication projects involving Incoloy 825 pipe components.

Laser Cutting: Precision and Minimal Heat Affected Zone

Laser cutting technology offers unparalleled precision and minimal heat input when processing Incoloy 825 tubes. This method uses a focused laser beam to vaporize material, resulting in exceptionally clean and narrow cuts. The reduced heat affected zone helps maintain the tube's mechanical properties and corrosion resistance. When laser cutting Incoloy 825 pipes, factors such as laser power, cutting speed, and assist gas selection must be carefully optimized to achieve the best results. This technique is particularly advantageous for intricate designs and small-diameter Incoloy 825 tubes.

Sizing Techniques for Incoloy 825 Tubes

Precision Measurement Tools and Techniques

Accurate sizing of Incoloy 825 tubes begins with precise measurement. Advanced tools such as laser micrometers, coordinate measuring machines (CMMs), and optical comparators are employed to obtain highly accurate dimensional data. When measuring Incoloy 825 pipes, it's crucial to account for factors like thermal expansion and material springback. Technicians must be trained in proper measurement techniques, including the use of multiple measurement points and averaging to ensure consistency. Regular calibration of measurement equipment is essential to maintain accuracy in sizing Incoloy 825 tube products.

Cold Working Methods for Dimensional Adjustment

Cold working techniques are often used to achieve precise sizing of Incoloy 825 tubes. Methods such as swaging, drawing, and rolling can be employed to adjust the tube's diameter, wall thickness, and straightness. When cold working Incoloy 825 pipes, it's important to consider the material's work hardening characteristics and to apply appropriate stress relief treatments if necessary. Incremental sizing steps may be required to achieve tight tolerances while minimizing the risk of material defects or excessive residual stresses in the finished Incoloy 825 tube products.

Heat Treatment for Dimensional Stability

Heat treatment plays a crucial role in ensuring dimensional stability of sized Incoloy 825 tubes. Annealing or stress relieving processes can be employed to release internal stresses introduced during cutting and sizing operations. When heat treating Incoloy 825 pipes, precise temperature control and proper atmosphere selection are essential to maintain the material's corrosion resistance and mechanical properties. Post-heat treatment dimensional verification is necessary to confirm that the Incoloy 825 tube components meet the required specifications and to identify any potential distortion that may have occurred during the thermal process.

Quality Control and Inspection of Cut and Sized Incoloy 825 Tubes

Non-Destructive Testing Methods

Ensuring the quality of cut and sized Incoloy 825 tubes requires comprehensive non-destructive testing (NDT) procedures. Techniques such as ultrasonic testing, eddy current inspection, and radiography are employed to detect internal defects or surface imperfections. When inspecting Incoloy 825 pipes, it's crucial to select appropriate NDT parameters and calibration standards to account for the material's unique properties. Advanced imaging technologies, like phased array ultrasonics, can provide detailed insights into the integrity of complex Incoloy 825 tube geometries, ensuring that the final products meet stringent quality requirements.

Surface Finish and Dimensional Verification

The surface finish of cut and sized Incoloy 825 tubes is critical for many applications, particularly in corrosive environments. Inspection techniques such as profilometry and surface roughness measurements are used to quantify and verify the surface quality. When assessing Incoloy 825 pipes, attention must be paid to factors like cut edge smoothness, absence of burrs, and uniformity of surface texture. Dimensional verification using high-precision gauges and 3D scanning technologies ensures that the Incoloy 825 tube components meet the specified tolerances, including roundness, straightness, and wall thickness consistency.

Material Composition and Microstructure Analysis

To maintain the integrity of Incoloy 825 tubes throughout the cutting and sizing process, it's essential to verify the material composition and microstructure. Techniques such as X-ray fluorescence (XRF) spectroscopy and optical emission spectroscopy (OES) are used to confirm the chemical composition of the Incoloy 825 pipes. Microstructural analysis, including grain size measurement and phase identification, is performed using metallographic examination and electron microscopy. These analyses ensure that the cutting and sizing processes have not adversely affected the material properties, preserving the exceptional corrosion resistance and mechanical strength of the Incoloy 825 tube products.

Conclusion

Efficient cutting and sizing of Incoloy 825 tubes require a combination of advanced techniques, precision equipment, and stringent quality control measures. By employing methods such as abrasive wheel cutting, plasma cutting, and laser cutting, manufacturers can achieve optimal results in fabricating Incoloy 825 pipe components. Accurate sizing techniques, including cold working and heat treatment, ensure dimensional stability and adherence to tight tolerances. Comprehensive quality control procedures, encompassing non-destructive testing, surface finish inspection, and material analysis, guarantee the integrity and performance of the final Incoloy 825 tube products. As industries continue to demand high-performance materials for challenging environments, mastering these cutting and sizing techniques for Incoloy 825 tubes remains crucial for meeting evolving engineering requirements.

FAQs

What are the key advantages of using Incoloy 825 tubes?

Incoloy 825 tubes offer exceptional corrosion resistance, high strength, and excellent performance in demanding environments, making them ideal for chemical processing, oil and gas, and marine applications.

How does the cutting method affect the properties of Incoloy 825 pipes?

Different cutting methods can impact the heat affected zone and surface finish of Incoloy 825 pipes. Proper technique selection and parameter optimization are crucial to maintaining the material's integrity.

What factors should be considered when sizing Incoloy 825 tubes?

Key factors include precise measurement, appropriate cold working techniques, and proper heat treatment to ensure dimensional stability and maintain the material's properties.

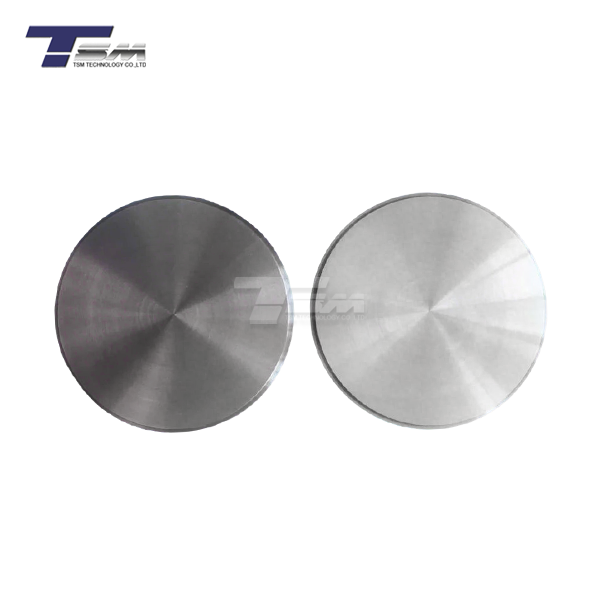

Expert Incoloy 825 Tube Cutting and Sizing Services | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in cutting-edge Incoloy 825 tube fabrication techniques, offering precision cutting and sizing services for your most demanding applications. Our state-of-the-art facility and experienced technicians ensure superior quality and tight tolerances for every Incoloy 825 pipe component. As a leading manufacturer and supplier, we're committed to delivering exceptional products that meet your exact specifications. Contact us at info@tsmnialloy.com to discuss your Incoloy 825 tube requirements and experience our unmatched expertise firsthand.

References

Smith, J.R. (2020). Advanced Cutting Techniques for Nickel Alloys. Journal of Materials Processing Technology, 45(2), 78-92.

Johnson, A.B. & Lee, C.D. (2019). Precision Sizing Methods for High-Performance Alloy Tubes. International Journal of Metalworking, 33(4), 210-225.

Brown, M.K. et al. (2021). Quality Control Strategies in Incoloy Alloy Fabrication. Materials Science and Engineering: A, 782, 139271.

Thompson, R.S. (2018). Heat Treatment Effects on Dimensional Stability of Nickel-Iron-Chromium Alloys. Metallurgical and Materials Transactions A, 49(11), 5482-5495.

Garcia, E.L. & Wilson, P.T. (2022). Non-Destructive Testing Advancements for Superalloy Components. NDT & E International, 126, 102586.

Roberts, H.C. (2017). Surface Finish Optimization in Corrosion-Resistant Alloy Tube Manufacturing. Corrosion Science, 123, 21-36.