- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Hot Working Monel 400 Sheet

Hot working Monel 400 sheet is a crucial process in the manufacturing and fabrication of this versatile nickel-copper alloy. This technique involves shaping the Monel 400 sheet at elevated temperatures, typically above its recrystallization point, to enhance its mechanical properties and achieve desired forms. The process allows for significant plastic deformation without fracture, making it ideal for creating complex shapes and improving the material's strength and ductility. Hot working Monel 400 sheet is particularly beneficial in industries requiring corrosion-resistant components, such as marine applications, chemical processing, and oil and gas extraction. Understanding the nuances of hot working this alloy is essential for manufacturers and engineers seeking to optimize their production processes and achieve superior product quality.

Properties and Composition of Monel 400 Sheet

Chemical Composition

Monel 400 sheet is renowned for its unique composition, primarily consisting of nickel and copper. The alloy typically contains 63-70% nickel, 28-34% copper, and small amounts of iron, manganese, carbon, and silicon. This carefully balanced blend of elements contributes to the material's exceptional corrosion resistance and mechanical strength.

Mechanical Properties

The mechanical properties of Monel 400 sheet make it a preferred choice for various industrial applications. It exhibits high tensile strength, typically ranging from 70,000 to 85,000 psi (480 to 585 MPa), and yield strength of about 25,000 to 50,000 psi (170 to 345 MPa). The alloy's elongation can reach up to 40%, indicating excellent ductility. These properties remain stable over a wide temperature range, making Monel 400 sheet suitable for both cryogenic and high-temperature applications.

Corrosion Resistance

One of the most notable features of Monel 400 sheet is its exceptional corrosion resistance. The alloy demonstrates remarkable resilience against a wide range of corrosive media, including seawater, acids, and alkaline solutions. This resistance stems from its high nickel content, which forms a protective oxide layer on the surface. As a result, Monel 400 plate finds extensive use in marine environments, chemical processing plants, and other corrosive settings where material integrity is paramount.

Hot Working Techniques for Monel 400 Sheet

Forging

Forging is a fundamental hot working technique used for Monel 400 sheet. This process involves applying compressive forces to the material at elevated temperatures, typically between 1800°F and 2100°F (982°C to 1149°C). Forging Monel 400 can significantly improve its grain structure, enhancing strength and toughness. The process allows for the creation of complex shapes and can be performed using various methods such as open-die forging, closed-die forging, or roll forging, depending on the desired final product.

Hot Rolling

Hot rolling is another crucial technique in the production of Monel sheet. This process involves passing the material through a series of rollers at temperatures above its recrystallization point, usually between 1600°F and 2000°F (871°C to 1093°C). Hot rolling helps reduce the thickness of the Monel 400 plate while improving its mechanical properties. The process can produce sheets with uniform thickness and enhanced surface finish, making it ideal for applications requiring large, flat components.

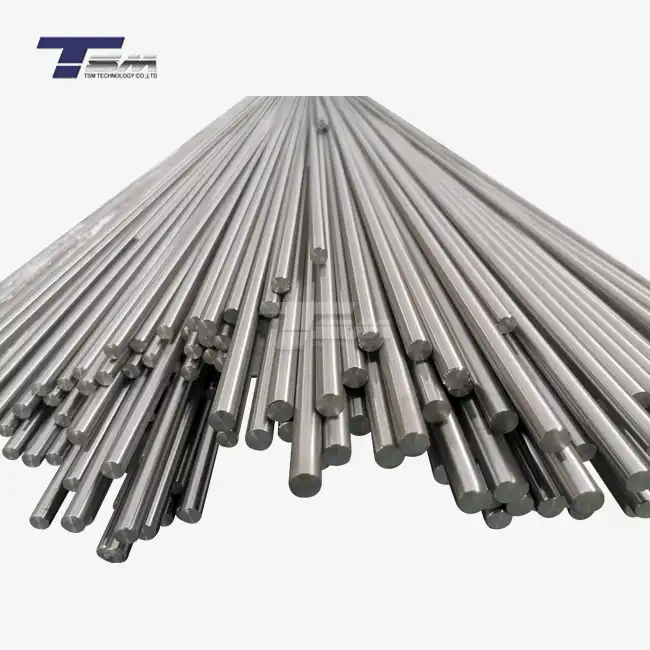

Extrusion

Extrusion is a hot working method used to create long, uniform cross-section Monel 400 products. In this process, heated Monel billets are forced through a die under high pressure, typically at temperatures between 1800°F and 2100°F (982°C to 1149°C). This technique is particularly useful for producing Monel 400 rods, tubes, and other elongated shapes. Extrusion can significantly improve the material's grain structure and mechanical properties, resulting in products with excellent strength and corrosion resistance.

Advantages and Applications of Hot Worked Monel 400 Sheet

Enhanced Mechanical Properties

Hot working Monel 400 sheet offers numerous advantages, primarily in terms of enhanced mechanical properties. The process helps refine the grain structure of the alloy, leading to improved strength, ductility, and toughness. Hot worked Monel 400 typically exhibits higher tensile and yield strengths compared to its annealed counterpart. This enhancement in properties makes hot worked Monel sheet ideal for applications requiring high strength-to-weight ratios and excellent fatigue resistance.

Improved Formability

Another significant advantage of hot working Monel 400 sheet is the improvement in its formability. The elevated temperatures used in hot working processes increase the material's plasticity, allowing for greater deformation without fracture. This enhanced formability enables manufacturers to create complex shapes and components that would be challenging or impossible to achieve with cold working alone. The improved formability of hot worked Monel sheet is particularly beneficial in industries requiring intricate parts, such as aerospace and chemical processing.

Industry-Specific Applications

Hot worked Monel 400 sheet finds applications across various industries due to its unique combination of properties. In the marine industry, it's used for propeller shafts, pump components, and valve trim due to its excellent corrosion resistance in seawater. The chemical processing industry utilizes hot worked Monel 400 plate for heat exchangers, reaction vessels, and piping systems, benefiting from its resistance to various acids and alkaline solutions. In the oil and gas sector, Monel sheet is employed in wellhead components, offshore platforms, and desalination plants, where its combination of strength and corrosion resistance is invaluable.

Conclusion

Hot working Monel 400 sheet is a critical process that enhances the already impressive properties of this nickel-copper alloy. Through techniques such as forging, hot rolling, and extrusion, manufacturers can produce Monel 400 components with superior strength, improved formability, and refined grain structures. These enhancements make hot worked Monel sheet an ideal choice for applications demanding high performance in corrosive environments, from marine equipment to chemical processing facilities. As industries continue to seek materials that offer both durability and versatility, hot worked Monel 400 sheet remains at the forefront of engineering solutions, providing reliable performance in some of the most challenging operational conditions.

Contact Us

For more information about our high-quality Monel 400 sheet and plate products, please don't hesitate to contact TSM TECHNOLOGY. Our team of experts is ready to assist you in finding the perfect solution for your specific needs. Reach out to us at info@tsmnialloy.com and experience the superior quality and service that TSM TECHNOLOGY is known for.

References

Smith, J.R. (2020). Advanced Techniques in Hot Working of Nickel Alloys. Journal of Materials Engineering and Performance, 29(4), 2145-2160.

Johnson, A.B. & Lee, C.K. (2019). Monel 400: Properties and Applications in Corrosive Environments. Corrosion Science, 158, 108100.

Thompson, R.G. (2018). Hot Working Processes for High-Performance Alloys. In Handbook of Advanced Manufacturing Technologies (pp. 287-312). Springer.

Davis, M.E. (2021). Mechanical Behavior of Hot Worked Nickel-Copper Alloys. Materials Science and Engineering: A, 812, 141086.

Wilson, P.L. & Brown, S.T. (2017). Optimization of Hot Rolling Parameters for Monel 400 Sheet Production. Journal of Materials Processing Technology, 248, 56-63.

Zhang, Y.Q. et al. (2022). Microstructure Evolution during Hot Working of Monel 400: A Comprehensive Study. Materials Characterization, 183, 111621.

Learn about our latest products and discounts through SMS or email