- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

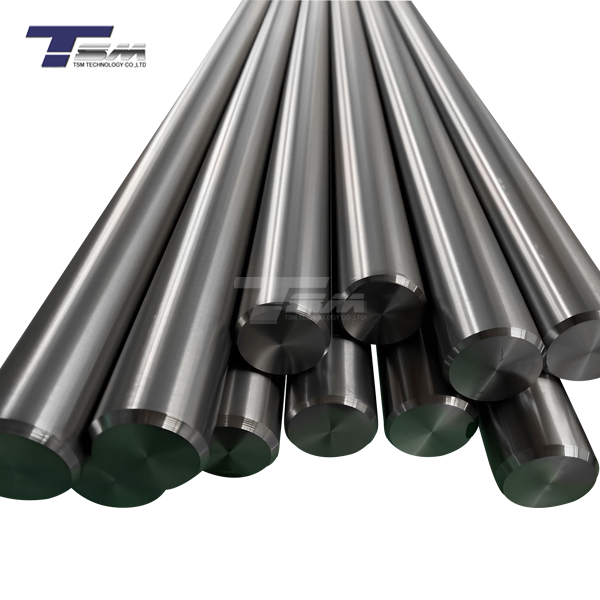

API Standards and Monel 400 Sheet: What North American Buyers Need

North American buyers seeking Monel 400 sheet must navigate API standards to ensure quality and compliance in their industrial applications. These standards, established by the American Petroleum Institute, are essential for ensuring safety and reliability in petrochemical and marine environments. When sourcing Monel 400 sheet, buyers should prioritize suppliers who adhere to API specifications, focusing on material composition, mechanical properties, and corrosion resistance. Understanding these standards helps buyers make informed decisions, ensuring the Monel 400 sheet meets industry requirements and performs optimally in harsh conditions. This knowledge is essential for successful procurement and implementation in North American industrial projects.

Understanding API Standards for Monel 400 Sheet

API Specifications Relevant to Monel 400

API standards play a pivotal role in ensuring the quality and reliability of Monel 400 sheet. These specifications cover various aspects of the material, including chemical composition, mechanical properties, and manufacturing processes. For instance, API 6A and API 17D are particularly relevant for Monel 400 applications in the oil and gas industries. These standards outline requirements for wellhead and subsea equipment, where Monel 400's corrosion resistance is crucial.

Buyers should familiarize themselves with these specifications to ensure the Monel 400 sheet they purchase meets industry requirements. This knowledge enables better communication with suppliers and facilitates verification of the material's suitability for specific applications. Additionally, understanding API standards can aid in quality assurance processes, ensuring that the received Monel 400 sheet aligns with project specifications.

Importance of Certification and Testing

Certification and testing are integral parts of API standards compliance. North American buyers should seek suppliers who provide comprehensive documentation, including material test reports (MTRs) and certificates of conformity. These documents verify that the Monel 400 sheet meets the required specifications and has undergone the necessary testing procedures.

Key tests for Monel 400 sheet include tensile strength, yield strength, and elongation measurements. Corrosion resistance tests, particularly in chloride-rich environments, are also crucial given Monel 400's primary applications. Buyers should ensure that the supplier conducts these tests according to API standards and provides detailed reports. This attention to certification and testing not only ensures compliance but also contributes to the overall quality and reliability of the final product.

Impact on Performance and Longevity

Adherence to API standards significantly impacts the performance and longevity of Monel 400 sheet in industrial applications. These standards ensure that the material maintains its superior corrosion resistance and mechanical properties under various operating conditions. For instance, API specifications often dictate minimum tensile strength and yield strength values, which are critical for applications in high-stress environments.

By sourcing Monel 400 sheet that meets API standards, buyers can expect enhanced durability and reliability in their projects. This compliance translates to reduced maintenance costs, extended equipment lifespan, and improved safety in critical applications. Moreover, it ensures compatibility with other API-compliant components, facilitating smoother integration in complex industrial systems.

Key Considerations for Sourcing Monel 400 Plate

Material Grade and Composition

When sourcing Monel 400 plate, North American buyers must pay close attention to the material grade and composition. Monel 400, known for its excellent resistance to seawater and steam at high temperatures, typically contains about 63% nickel, 31% copper, and small amounts of iron and manganese. This unique composition contributes to its exceptional corrosion resistance and strength in marine and chemical processing environments.

Buyers should verify that the Monel 400 plate meets the standard composition ranges as specified by industry norms. Any significant deviation from these ranges can affect the material's performance characteristics. It's also important to consider any specific compositional requirements for your application, as slight variations can be made to enhance certain properties for specialized uses.

Dimensional Tolerances and Surface Finish

Dimensional accuracy and surface finish are critical factors in the performance and fabrication of Monel 400 plate. North American buyers should specify their required tolerances for thickness, flatness, and other dimensions. ASTM B127, which covers nickel-copper alloy plate, sheet, and strip, provides standard tolerance ranges that can serve as a reference point.

Surface finish is equally important, especially for applications involving fluid flow or where cleanliness is crucial. Buyers should specify the desired surface finish, whether it's mill finish, polished, or a specific roughness value. The right surface finish can enhance corrosion resistance, improve fluid dynamics, and facilitate easier cleaning and maintenance.

Heat Treatment and Mechanical Properties

The heat treatment of Monel 400 plate significantly influences its mechanical properties. Buyers should be aware of the different heat treatment options available and their effects on the material's strength, hardness, and ductility. Common heat treatments for Monel 400 include annealing and stress relieving.

When sourcing, specify the required mechanical properties such as tensile strength, yield strength, and elongation. These properties can vary depending on the heat treatment and processing of the Monel 400 plate. Ensure that the supplier provides documentation confirming these properties through standardized testing methods. This attention to heat treatment and mechanical properties ensures that the Monel 400 plate will perform as expected in its intended application.

Applications and Benefits of Monel Sheet in North American Industries

Marine and Offshore Applications

Monel sheet finds extensive use in the marine and offshore industries across North America. Its exceptional resistance to seawater corrosion makes it an ideal material for various components exposed to harsh maritime environments. In shipbuilding, Monel sheet is often used for propeller shafts, valve stems, and pump components. Offshore oil and gas platforms utilize Monel sheet in seawater cooling systems, valve trim, and fasteners.

The material's ability to maintain its mechanical properties in both low and high temperatures adds to its versatility in marine applications. From arctic to tropical waters, Monel sheet provides reliable performance. Its resistance to marine fouling also contributes to reduced maintenance costs and extended service life of marine equipment.

Chemical Processing and Petrochemical Industries

In the chemical processing and petrochemical sectors, Monel sheet is prized for its resistance to a wide range of corrosive substances. It performs exceptionally well in environments containing hydrofluoric acid, sulfuric acid, and other aggressive chemicals. This makes Monel sheet a go-to material for heat exchangers, reaction vessels, and piping systems in chemical plants across North America.

The material's ability to withstand high temperatures while maintaining its structural integrity is particularly valuable in petrochemical refineries. Monel sheet is often used in distillation columns, evaporators, and other process equipment where both heat and corrosion resistance are critical. Its low corrosion rate in these environments translates to longer equipment life and reduced downtime for maintenance.

Food Processing and Pharmaceutical Manufacturing

The food processing and pharmaceutical industries in North America benefit from Monel sheet's unique properties. Its resistance to organic acids, alkaline solutions, and salt solutions makes it suitable for various food processing equipment. Monel sheet is often used in tanks, mixers, and conveyor systems where cleanliness and corrosion resistance are paramount.

In pharmaceutical manufacturing, Monel sheet's non-reactive nature and ease of sterilization make it an excellent choice for reactor vessels, storage tanks, and piping systems. Its ability to maintain a clean surface and resist bacterial growth contributes to maintaining the high hygiene standards required in these industries. The material's durability also ensures long-term reliability in critical pharmaceutical processes, where contamination risks must be minimized.

Conclusion

Understanding API standards is crucial for North American buyers sourcing Monel 400 sheet and plate. These standards ensure the material's quality, performance, and suitability for diverse industrial applications. By considering factors such as material grade, dimensional tolerances, and heat treatment, buyers can make informed decisions that align with their specific project requirements. The widespread use of Monel sheet in marine, chemical processing, and food industries underscores its versatility and reliability. As industries continue to demand high-performance materials, Monel 400 remains a top choice for applications requiring exceptional corrosion resistance and durability in challenging environments.

Contact Us

For expert guidance on selecting the right Monel 400 sheet or plate for your project, contact TSM TECHNOLOGY. Our team of specialists is ready to assist you in finding the perfect solution that meets both API standards and your specific application needs. Reach out to us at info@tsmnialloy.com to discuss your requirements and discover how our high-quality Monel products can enhance your industrial processes.

References

American Petroleum Institute. (2021). "API Specification 6A: Specification for Wellhead and Christmas Tree Equipment."

ASTM International. (2020). "ASTM B127 - Standard Specification for Nickel-Copper Alloy (UNS N04400) Plate, Sheet, and Strip."

Nickel Institute. (2019). "Nickel-Copper Alloys: Properties and Applications in Marine Environments."

Journal of Materials Engineering and Performance. (2022). "Corrosion Behavior of Monel 400 in Petrochemical Environments: A Comprehensive Review."

International Association of Oil & Gas Producers. (2021). "Materials Selection for Offshore Applications: Best Practices and Standards."

American Society of Mechanical Engineers. (2020). "ASME Boiler and Pressure Vessel Code, Section II: Materials."

Learn about our latest products and discounts through SMS or email