Understanding Hastelloy C276 and Its Properties

Composition and Characteristics of Hastelloy C276

Hastelloy C276 is a remarkable nickel-chromium-molybdenum alloy renowned for its exceptional corrosion resistance and mechanical strength. This superior alloy typically contains approximately 57% nickel, 16% chromium, 16% molybdenum, and smaller amounts of tungsten, iron, and other elements. The unique composition of Hastelloy C276 contributes to its outstanding resistance to pitting, crevice corrosion, and stress corrosion cracking in aggressive environments.

The alloy's high molybdenum content enhances its resistance to reducing chemicals, while the chromium protects oxidizing media. This combination of elements makes Hastelloy C276 tubing an ideal choice for applications involving harsh chemicals, high temperatures, and corrosive environments. The material's excellent ductility and weldability further contribute to its versatility in various industrial sectors.

Applications of Hastelloy C276 Tubes and Pipes

Hastelloy C276 seamless pipes and tubes find extensive use across multiple industries due to their superior performance characteristics. In the chemical processing industry, these components are utilized in reactor vessels, heat exchangers, and piping systems that handle corrosive chemicals and acids. The offshore oil and gas sector relies on Hastelloy C276 tubing for subsea equipment, wellhead components, and process piping exposed to seawater and hydrogen sulfide-containing environments.

The nuclear power industry employs Hastelloy C276 tubes in spent fuel reprocessing facilities and waste treatment systems. Additionally, this alloy is crucial in pollution control equipment, desalination plants, and pharmaceutical manufacturing processes where material integrity is paramount. The versatility of Hastelloy C276 makes it an indispensable material for engineers and designers tackling challenging corrosion problems in various industrial applications.

Importance of Proper Hot Working Techniques

Employing appropriate hot working techniques is crucial for maintaining and enhancing the desirable properties of Hastelloy C276 tubes. The hot working process allows for significant plastic deformation of the material, resulting in refined grain structure and improved mechanical properties. Proper hot working can lead to increased strength, enhanced ductility, and better overall performance of the Hastelloy C276 tubing.

Furthermore, correctly executed hot working techniques help in achieving uniform wall thickness, precise dimensional tolerances, and smooth surface finishes in Hastelloy C276 seamless pipes. These factors are critical for ensuring the longevity and reliability of components in corrosive and high-stress environments. By optimizing hot working parameters, manufacturers can produce Hastelloy C276 tubes that meet or exceed industry standards and customer specifications, ultimately contributing to the safety and efficiency of various industrial processes.

Hot Rolling Process for Hastelloy C276 Tubes

Principles of Hot Rolling

Hot rolling is a fundamental hot working technique used in the production of Hastelloy C276 tubes. This process involves heating the alloy to temperatures typically ranging from 1050°C to 1200°C, well above its recrystallization temperature. At these elevated temperatures, the material becomes more malleable, allowing for significant plastic deformation with relatively low applied forces.

The hot rolling process for Hastelloy C276 tubing begins with a cylindrical billet or ingot, which is passed through a series of rotating rolls. As the material moves through the rolls, it is compressed and elongated, gradually taking on the desired tubular shape. The continuous deformation during hot rolling helps break down the cast structure of the alloy, resulting in a more refined and homogeneous microstructure.

Temperature Control and Its Impact

Precise temperature control is crucial during the hot rolling of Hastelloy C276 tubes. The working temperature must be carefully maintained within the optimal range to ensure proper deformation without compromising the alloy's properties. If the temperature is too low, the material may become too resistant to deformation, leading to excessive stress on the rolling equipment and potential surface defects in the tubing.

Conversely, if the temperature is too high, it can result in excessive grain growth or even partial melting of the alloy, negatively impacting the mechanical properties of the finished Hastelloy C276 seamless pipe. Advanced temperature monitoring and control systems are employed to maintain the ideal temperature throughout the rolling process, ensuring consistent quality and properties in the final product.

Advantages and Limitations of Hot Rolling

Hot rolling offers several advantages in the production of Hastelloy C276 tubes. The process allows for significant reduction in cross-sectional area, enabling the creation of long, continuous lengths of tubing with uniform properties. The high-temperature deformation also helps in breaking down and redistributing any segregation present in the original cast structure, leading to improved homogeneity in the final product.

However, hot rolling also has some limitations when working with Hastelloy C276. The high-temperature oxidation resistance of the alloy can lead to the formation of tenacious oxide scales during the rolling process. These scales must be carefully removed to prevent surface defects in the finished tubing. Additionally, the complex alloying elements in Hastelloy C276 can make it more susceptible to hot shortness or cracking during rolling if process parameters are not precisely controlled.

Hot Extrusion and Forging Techniques for Hastelloy C276

Hot Extrusion Process and Its Benefits

Hot extrusion is another valuable technique used in the production of Hastelloy C276 tubes and pipes. This process involves forcing a heated billet of the alloy through a die with a specific cross-sectional profile. For Hastelloy C276 tubing, the die typically has an annular opening to create the hollow tubular shape. The extrusion process is carried out at temperatures similar to those used in hot rolling, typically between 1050°C and 1200°C.

One of the primary benefits of hot extrusion for Hastelloy C276 is the ability to produce complex cross-sectional shapes with high dimensional accuracy. This technique is particularly useful for creating Hastelloy C276 seamless pipes with specialized profiles or internal features. The high compressive forces involved in extrusion also contribute to a very fine-grained structure in the finished product, enhancing the mechanical properties and corrosion resistance of the Hastelloy C276 tubing.

Hot Forging Techniques for Hastelloy C276

Hot forging is a versatile hot working technique that can be applied to Hastelloy C276 for producing custom tubular components or preforms for further processing. The forging process involves shaping the heated alloy using localized compressive forces, typically applied through dies or hammers. For Hastelloy C276 tubes, hot forging can be used to create thick-walled sections, flanges, or specialized end fittings that are integral to the tube.

The high degree of plastic deformation achieved during hot forging results in a refined grain structure and improved mechanical properties in the forged regions of Hastelloy C276 components. This technique is particularly valuable for creating high-strength, corrosion-resistant fittings and transitions in Hastelloy C276 piping systems used in extreme environments, such as those found in chemical processing plants or offshore oil and gas installations.

Challenges in Hot Working Hastelloy C276

While hot working techniques offer numerous advantages in shaping Hastelloy C276 tubes, they also present several challenges that must be carefully managed. One significant challenge is the high strength of the alloy even at elevated temperatures, which requires substantial force and energy input during the hot working processes. This can lead to increased wear on tooling and equipment, necessitating the use of specialized, high-durability materials in the manufacturing setup.

Another challenge in hot working Hastelloy C276 is its susceptibility to elemental segregation during solidification and subsequent hot working. This can result in localized variations in composition and properties if not properly addressed. Careful control of heating rates, holding times, and deformation parameters is essential to ensure homogeneous properties throughout the Hastelloy C276 tubing. Additionally, the potential for surface oxidation during hot working necessitates stringent surface preparation and finishing processes to maintain the superior corrosion resistance of Hastelloy C276 seamless pipes and tubes.

Conclusion

Hot working techniques play a crucial role in the production of high-quality Hastelloy C276 tubes and pipes. Through carefully controlled processes such as hot rolling, extrusion, and forging, manufacturers can harness the exceptional properties of this corrosion-resistant alloy to create components that meet the demanding requirements of various industries. The success of these techniques relies on a deep understanding of Hastelloy C276's behavior at elevated temperatures and precise control of process parameters. As industries continue to push the boundaries of material performance, the ongoing refinement of hot working techniques for Hastelloy C276 will remain essential in delivering superior alloy products that can withstand the most challenging environments.

Contact Us

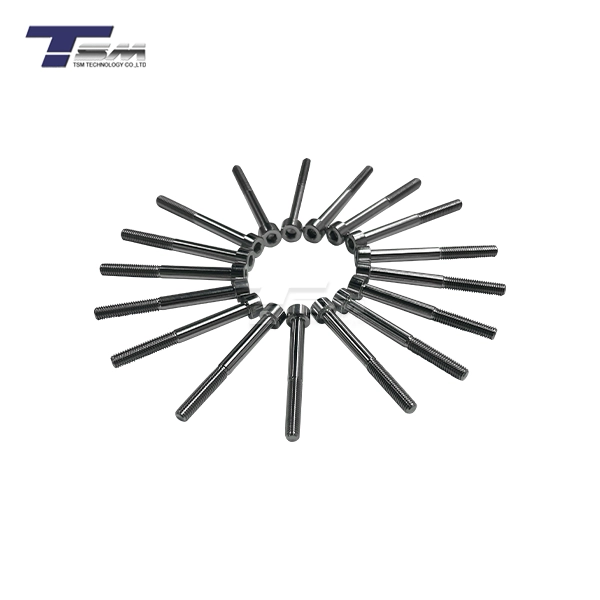

For more information about our Hastelloy C276 tubes, seamless pipes, and other superior alloy products, please don't hesitate to contact us. Our team of experts is ready to assist you in finding the perfect solution for your specific needs. Contact TSM TECHNOLOGY today at info@tsmnialloy.com to learn more about our high-quality Hastelloy C276 products and how they can benefit your projects.