The Fundamentals of Cold Drawing Hastelloy C276 Tubes

Material Properties of Hastelloy C276

Hastelloy C276 is a remarkable nickel-based superalloy renowned for its outstanding corrosion resistance and mechanical properties. This alloy's composition typically includes approximately 57% nickel, 16% chromium, 16% molybdenum, and small amounts of tungsten, cobalt, and other elements. The unique combination of these elements provides Hastelloy C276 with exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking in both oxidizing and reducing environments.

The alloy's high molybdenum content contributes to its superior resistance to localized corrosion, particularly in environments containing chloride. Additionally, the presence of chromium forms a protective oxide layer on the surface, further enhancing its corrosion resistance. These properties make Hastelloy C276 an ideal material for manufacturing tubes and pipes that can withstand harsh chemical environments and elevated temperatures.

Preparation for Cold Drawing

Before the cold drawing process begins, Hastelloy C276 tubes undergo thorough preparation to ensure optimal results. The initial step involves producing a hollow tube through hot extrusion or piercing methods. This pre-form tube, often referred to as a "mother tube," serves as the starting point for the cold drawing process.

The mother tube is carefully inspected for any surface defects or inconsistencies that could affect the final product quality. Any imperfections are removed through grinding or machining to create a smooth, uniform surface. The tube is then cleaned to remove any contaminants that could interfere with the drawing process or compromise the material's properties.

To facilitate the cold drawing process, the Hastelloy C276 tubing may be annealed to reduce its hardness and increase its ductility. This heat treatment process helps prevent cracking or fracturing during the subsequent deformation steps. The annealing temperature and duration are carefully controlled to achieve the desired material properties without compromising the alloy's corrosion resistance.

The Cold Drawing Process

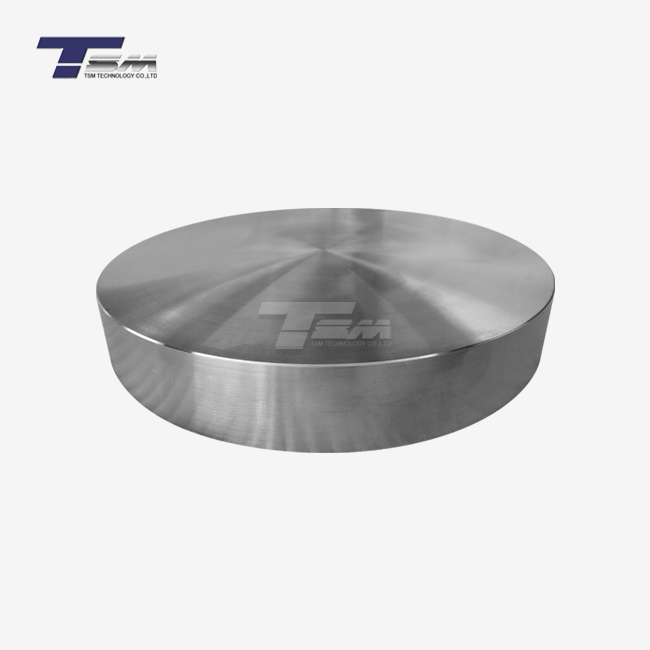

The cold drawing of Hastelloy C276 tubes is a multi-stage process that progressively reduces the tube's diameter while increasing its length and wall thickness. The process begins by inserting the prepared mother tube into a drawing die, which has a carefully designed internal profile. A mandrel, typically made of a high-strength tool steel, is positioned inside the tube to control the inner diameter and wall thickness during drawing.

As the tube is pulled through the die, it undergoes plastic deformation, reducing its cross-sectional area and elongating its length. The mandrel ensures that the inner diameter remains consistent while the outer diameter is reduced. This process is repeated through a series of dies with progressively smaller diameters until the desired tube dimensions are achieved.

Between drawing passes, the Hastelloy C276 tube may undergo intermediate annealing to restore its ductility and prevent work hardening from causing cracks or fractures. The number of drawing passes and intermediate annealing steps depends on the initial tube dimensions, the desired final dimensions, and the specific mechanical properties required for the application.

Advantages of Cold-Drawn Hastelloy C276 Tubing

Enhanced Mechanical Properties

The cold drawing process significantly improves the mechanical properties of Hastelloy C276 tubing. As the material is work-hardened during drawing, its yield strength and tensile strength increase substantially. This enhancement in strength allows for the production of thinner-walled tubes without compromising their load-bearing capacity, resulting in weight savings and improved performance in high-pressure applications.

Moreover, the cold drawing process refines the grain structure of the Hastelloy C276 alloy, leading to improved fatigue resistance and enhanced creep properties. These characteristics are particularly valuable in applications involving cyclic loading or prolonged exposure to high temperatures, such as in heat exchangers or chemical processing equipment.

Improved Surface Finish and Dimensional Accuracy

Cold-drawn Hastelloy C276 tubes exhibit superior surface finish compared to their hot-worked counterparts. The drawing process smoothens surface irregularities and reduces roughness, resulting in a polished appearance and improved fluid flow characteristics. This enhanced surface quality is particularly beneficial in applications where cleanliness and minimal friction are critical, such as in pharmaceutical or food processing industries.

Furthermore, the cold drawing process allows for exceptional dimensional control, producing Hastelloy C276 tubing with tight tolerances on both inner and outer diameters. This precision is crucial for applications requiring exact fit and compatibility with other components, such as in heat exchanger tube bundles or precision instrumentation. The ability to maintain consistent wall thickness throughout the length of the tube also contributes to uniform strength and performance characteristics.

Customization and Versatility

Cold drawing offers a high degree of customization in the production of Hastelloy C276 tubing. Manufacturers can tailor the tube dimensions, including outer diameter, inner diameter, and wall thickness, to meet specific application requirements. This flexibility allows for the production of both standard and non-standard sizes, accommodating a wide range of engineering needs.

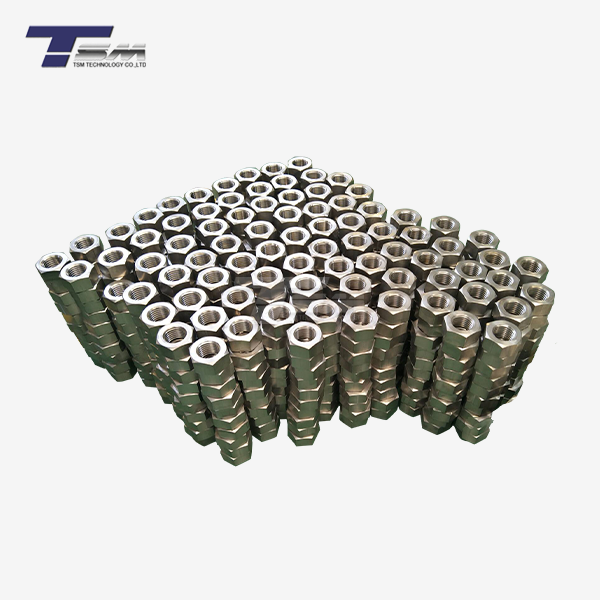

Additionally, the cold drawing process can be used to create Hastelloy C276 tubes with special profiles or cross-sections. By using dies and mandrels with custom shapes, manufacturers can produce oval, square, or other non-circular tubes for specialized applications. This versatility in shaping capabilities expands the potential uses of Hastelloy C276 tubing across various industries and engineering challenges.

Applications and Considerations for Cold-Drawn Hastelloy C276 Tubes

Industry-Specific Applications

Cold-drawn Hastelloy C276 tubes find extensive use across numerous industries due to their exceptional corrosion resistance and mechanical properties. In the chemical processing industry, these tubes are employed in the construction of heat exchangers, reactors, and piping systems that handle aggressive chemicals and high-temperature fluids. The aerospace sector utilizes Hastelloy C276 tubing in hydraulic systems and fuel lines, where resistance to both corrosion and high-pressure is paramount.

The oil and gas industry benefits from cold-drawn Hastelloy C276 seamless pipes in offshore platforms, desalination plants, and sour gas processing facilities. The alloy's resistance to chloride-induced stress corrosion cracking makes it ideal for these marine and high-chloride environments. In the nuclear power industry, Hastelloy C276 tubing is used in waste processing systems and steam generators, where its corrosion resistance and high-temperature strength are critical for safe and efficient operation.

Design and Engineering Considerations

When incorporating cold-drawn Hastelloy C276 tubes into engineering designs, several factors must be considered to ensure optimal performance. The increased strength resulting from the cold drawing process allows for the use of thinner wall thicknesses, potentially reducing material costs and overall weight. However, engineers must carefully evaluate the stress levels and operating conditions to determine the appropriate wall thickness for each application.

The superior surface finish of cold-drawn tubes can improve fluid flow characteristics and reduce the risk of fouling or corrosion initiation. This factor should be considered when designing piping systems or heat exchangers, as it can lead to improved efficiency and reduced maintenance requirements. Additionally, the tight dimensional tolerances achieved through cold drawing facilitate precise fitting and assembly, which is crucial in applications requiring leak-tight connections or exact component matching.

Quality Control and Testing

Maintaining the highest quality standards is essential in the production of cold-drawn Hastelloy C276 tubing. Rigorous quality control measures are implemented throughout the manufacturing process to ensure consistency and reliability. Non-destructive testing methods, such as ultrasonic testing and eddy current inspection, are employed to detect any internal or surface defects that may have developed during the drawing process.

Mechanical testing, including tensile strength, yield strength, and elongation measurements, is conducted to verify that the cold-drawn tubes meet or exceed the specified mechanical properties. Dimensional checks are performed at various stages of production to ensure compliance with tight tolerance requirements. Additionally, corrosion testing may be conducted to confirm the material's resistance to specific chemical environments relevant to its intended application.

To guarantee the authenticity and traceability of the Hastelloy C276 tubing, manufacturers maintain comprehensive documentation, including material certifications, test reports, and production records. This documentation is crucial for quality assurance and regulatory compliance, particularly in industries with stringent safety and performance requirements.

Conclusion

Cold drawing is a pivotal manufacturing technique that significantly enhances the properties and performance of Hastelloy C276 tubes and pipes. This process not only improves mechanical strength and surface finish but also allows for precise dimensional control and customization. The resulting cold-drawn Hastelloy C276 tubing exhibits superior corrosion resistance, making it indispensable in challenging industrial applications. As industries continue to demand materials capable of withstanding extreme conditions, cold-drawn Hastelloy C276 tubes stand as a testament to engineering innovation and material science advancement.

Contact Us

For more information on our cold-drawn Hastelloy C276 tubes and other superior alloy products, please don't hesitate to reach out. Contact TSM TECHNOLOGY at info@tsmnialloy.com to discuss your specific requirements and how our expertise can benefit your projects.