- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Cold Drawing Improves Surface Finish on Metal Tubes?

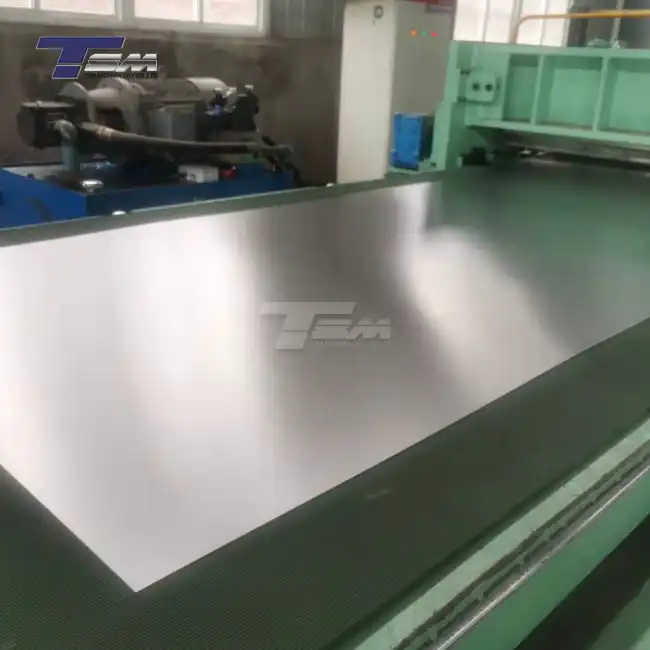

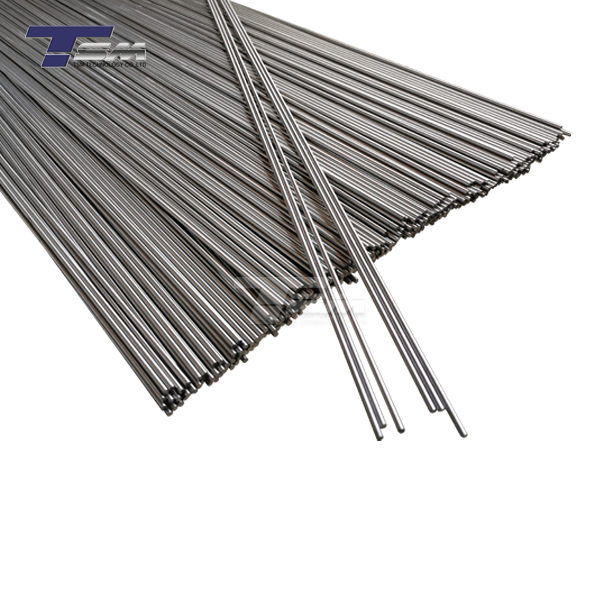

When it comes to manufacturing high-quality metal tubes, achieving a flawless surface finish is paramount, especially for industries relying on precision-engineered components. Cold drawing, a transformative metalworking process, plays a pivotal role in enhancing the surface quality of metal tubes. By pulling metal through a die at room temperature, this technique refines the tube's exterior, eliminating imperfections and boosting dimensional accuracy. The result? A smoother, more polished surface that not only elevates aesthetics but also enhances performance in demanding applications. For superior nickel alloys and special metals, such as Monel, Inconel, and Hastelloy, used in industries worldwide, this process ensures tubes meet stringent quality standards, making them ideal for precision engineering and machine shop applications.

Understanding the Mechanics of Cold Drawing

What Is Cold Drawing?

Cold drawing is a metalworking technique where metal tubes, rods, or wires are pulled through a die at ambient temperatures to reduce their diameter and enhance their properties. Unlike hot working methods, which rely on elevated temperatures, this process leverages mechanical force to shape the metal. The absence of heat preserves the material's inherent strength while allowing for precise control over dimensions and surface quality. For superior alloys such as Incoloy or Hastelloy, this method is particularly valuable, as it maintains the alloy's corrosion resistance and mechanical integrity, critical for applications in harsh environments like aerospace, chemical processing, and marine engineering.

How Cold Drawing Enhances Surface Quality?

The magic of cold drawing lies in its ability to refine the surface of metal tubes. As the metal passes through the die, its outer layer undergoes intense compressive forces, smoothing out microscopic irregularities, scratches, and blemishes. This process also reduces surface roughness, often measured in Ra (roughness average) values, to levels as low as 0.2-0.8 micrometers, depending on the alloy and die specifications. For precision engineering, where tolerances are tight and surface imperfections can compromise performance, this level of refinement is indispensable. The result is a tube with a mirror-like finish, free from defects that could lead to corrosion or fatigue failure.

The Role of Lubrication in Surface Improvement

Lubrication is a silent hero in the cold drawing process, ensuring the metal glides smoothly through the die without galling or scratching. High-quality lubricants, often tailored to specific alloys, minimize friction between the tube and the die, preserving the surface integrity of materials like Monel or Inconel. This is especially crucial for special metals, as their unique compositions can make them prone to surface damage if not handled with care. By reducing frictional heat and wear, lubrication not only enhances surface finish but also extends the lifespan of the drawing equipment, ensuring consistent quality across large production runs.

Cold Drawing's Impact on Performance and Applications

Boosting Dimensional Precision for Critical Applications

Beyond surface finish, cold drawing excels in delivering unparalleled dimensional accuracy. The process can achieve tolerances as tight as ±0.01 mm, making it ideal for industries where precision is non-negotiable, such as aerospace, medical device manufacturing, and automotive engineering. For superior nickel alloys, this precision ensures that tubes fit seamlessly into complex assemblies, reducing the need for costly secondary machining. The smooth, uniform surface also minimizes stress concentrations, enhancing the tube's fatigue resistance - a critical factor in applications exposed to cyclic loading, such as turbine components or pressure vessels.

Enhancing Corrosion Resistance Through Surface Refinement

Surface finish isn't just about aesthetics; it plays a vital role in the longevity of metal tubes, especially those made from corrosion-resistant alloys like Hastelloy or Incoloy. A smoother surface reduces the number of crevices and pits where corrosive agents, such as saltwater or acidic chemicals, could initiate degradation. Cold drawing's ability to eliminate surface defects enhances the natural corrosion resistance of these alloys, making them indispensable in industries like oil and gas, where components are exposed to aggressive environments. This synergy between material properties and surface quality ensures that the tubes perform reliably over extended periods.

Tailoring Surface Finish to Industry Needs

Different industries demand varying levels of surface finish, and cold drawing offers the flexibility to meet these diverse requirements. For instance, in the pharmaceutical sector, metal tubes must have ultra-smooth surfaces to prevent bacterial adhesion and ensure compliance with hygiene standards. In contrast, the energy sector may prioritize surface durability to withstand abrasive conditions. By adjusting parameters such as die geometry, drawing speed, and lubrication, manufacturers can customize the surface finish of alloys like Monel or Inconel to suit specific applications, ensuring optimal performance and customer satisfaction.

Why Cold Drawing Is Essential for Superior Alloys?

Preserving Alloy Integrity During Processing

Superior nickel alloys, such as those supplied by TSM TECHNOLOGY, are engineered to deliver exceptional performance under extreme conditions. However, these materials are sensitive to processing techniques, and improper handling can compromise their properties. Cold drawing stands out as a preferred method because it avoids the high temperatures that could alter the alloy's microstructure or reduce its corrosion resistance. For example, alloys like Inconel 625, known for their high strength and oxidation resistance, retain their metallurgical stability during cold drawing, ensuring that the final product meets the rigorous demands of precision engineering and machine shops worldwide.

Meeting Stringent Quality Standards

At TSM TECHNOLOGY, quality is non-negotiable. Each superior alloy product undergoes meticulous inspection by professional inspectors to ensure it meets international standards, such as ASTM or ASME specifications. Cold drawing plays a crucial role in this quality assurance process by delivering tubes with a consistent surface finish and dimensional accuracy. For instance, a Hastelloy C276 tube, commonly used in chemical processing, must have a surface roughness below 0.4 micrometers to prevent stress corrosion cracking. Cold drawing, combined with TSM's strict quality control, ensures that every tube meets these exacting standards, building trust among global customers in industries ranging from aerospace to energy.

Driving Innovation in Alloy Applications

As a leader in the superior nickel alloy market, TSM TECHNOLOGY is committed to pushing the boundaries of material science. Cold drawing is not just a manufacturing process; it's a gateway to innovation. By refining the surface finish and mechanical properties of alloys, this technique enables the development of new applications, from ultra-thin-walled tubes for heat exchangers to high-strength components for deep-sea exploration. Over the past 14 years, since TSM's international journey began in Hong Kong in 2011, the company has leveraged cold drawing to bring advanced materials to market, solidifying its reputation as a reliable partner for precision engineering solutions worldwide.

Conclusion

Cold drawing is a game-changer in the world of metal tube manufacturing, offering a powerful combination of surface refinement, dimensional precision, and material integrity. For superior nickel alloys and special metals, this process ensures that tubes meet the exacting demands of industries worldwide, from aerospace to chemical processing. By delivering smooth, defect-free surfaces, cold drawing enhances performance, extends service life, and opens the door to innovative applications. At TSM TECHNOLOGY, this technique is a cornerstone of our commitment to quality, helping us provide precision-engineered solutions to machine shops and industries globally.

Contact Us

For more information on our superior nickel alloy and special metals products, including cold-drawn tubes, please don't hesitate to contact TSM TECHNOLOGY. Our team of experts is ready to assist you in finding the perfect solution for your precision engineering needs. Contact us at: info@tsmnialloy.com.

References

ASM International, Handbook of Metal Forming Processes, 2nd Edition, 2019.

Smith, J., Advanced Techniques in Metal Tube Manufacturing, Industrial Press, 2020.

Brown, T., Surface Engineering of Nickel Alloys, Materials Science Publishing, 2018.

Davis, R., Precision Engineering with Specialty Metals, Engineering Press, 2021.

Lee, K., Cold Working of High-Performance Alloys, Technical Publications, 2017.

Patel, M., Innovations in Metal Surface Finishing, Global Manufacturing Journal, 2022.

Learn about our latest products and discounts through SMS or email