- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

The Effect of Solution Annealing on Metal Microstructure

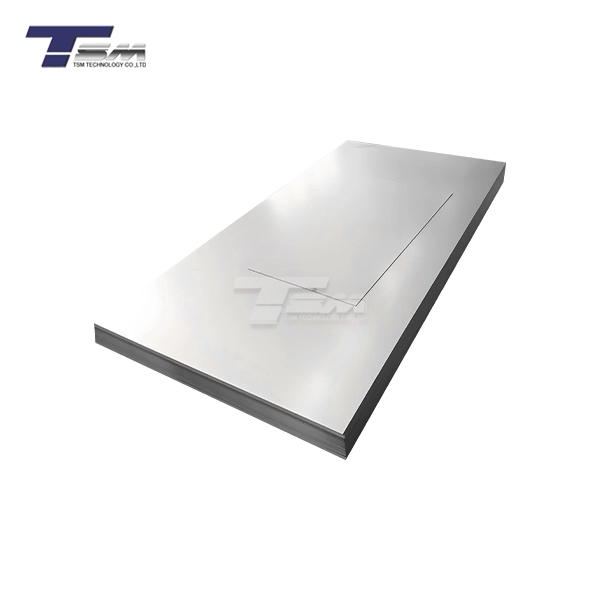

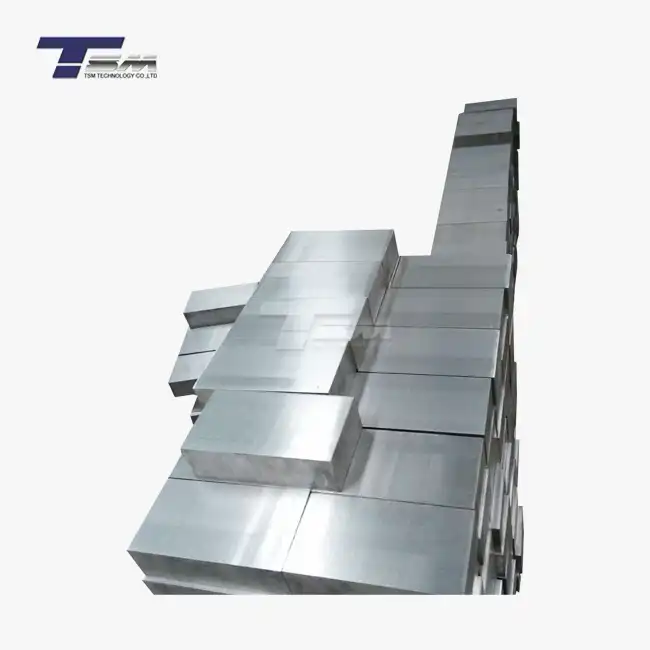

Solution annealing is a critical heat treatment process that significantly influences the microstructure of metals, particularly in superior nickel alloys and special metals. This thermal procedure involves heating the metal to a specific temperature, holding it for a predetermined time, and then rapidly cooling it. The primary effect of solution annealing on metal microstructure is the dissolution of precipitates, homogenization of the microstructure, and reduction of internal stresses. These changes lead to enhanced mechanical properties, improved corrosion resistance, and better overall performance of the metal. Understanding the intricacies of this process is crucial for manufacturers and users of high-performance alloys in various industrial applications.

Fundamentals of Solution Annealing

The Science Behind Solution Annealing

Solution annealing is rooted in the principles of metallurgy and thermodynamics. When a metal is heated to its solution annealing temperature, which is typically above its recrystallization temperature but below its melting point, several key phenomena occur. The elevated temperature increases atomic mobility within the crystal structure, allowing for the dissolution of secondary phases and precipitates into the matrix. This process creates a more homogeneous solid solution, effectively "resetting" the microstructure of the metal.

Temperature and Time Parameters

The effectiveness of solution annealing heavily depends on two critical parameters: temperature and time. The annealing temperature must be carefully selected based on the specific alloy composition to ensure complete dissolution of precipitates without causing grain growth or incipient melting. The holding time at this temperature is equally important, as it determines the extent of homogenization achieved. Insufficient time may result in incomplete dissolution, while excessive time can lead to undesirable grain coarsening.

Cooling Methods and Their Impact

The cooling rate following the annealing process plays a crucial role in preserving the homogenized structure. Rapid cooling, often achieved through water quenching, prevents the re-precipitation of dissolved elements, maintaining the supersaturated solid solution. However, the choice of cooling method must balance the desired microstructure with the risk of thermal shock and residual stresses. For some alloys, controlled cooling rates or air cooling may be more appropriate to achieve optimal properties.

Microstructural Changes During Solution Annealing

Dissolution of Precipitates

One of the primary effects of solution annealing on metal microstructure is the dissolution of precipitates. In many alloys, especially those used in high-temperature applications, precipitates form during service or previous heat treatments. These precipitates, while sometimes beneficial for certain properties, can also lead to embrittlement or reduced corrosion resistance. Solution annealing dissolves these precipitates back into the matrix, creating a more uniform microstructure. This dissolution process is particularly important for nickel-based superalloys, where the careful control of γ' and other precipitates is crucial for high-temperature performance.

Grain Structure Modification

Solution annealing can significantly affect the grain structure of metals. During the annealing process, recrystallization occurs, leading to the formation of new, strain-free grains. This process can help eliminate the effects of prior cold work or deformation. In some cases, controlled grain growth may be desirable to achieve specific mechanical properties. However, excessive grain growth can be detrimental, leading to reduced strength and toughness. The balance between recrystallization and grain growth is a critical aspect of solution annealing that metallurgists must carefully control.

Homogenization of Chemical Composition

Another crucial effect of solution annealing is the homogenization of the chemical composition throughout the metal. During solidification or previous processing steps, segregation of alloying elements can occur, leading to localized variations in composition. These compositional inhomogeneities can result in undesirable properties or behavior in certain regions of the material. Solution annealing promotes diffusion of alloying elements, equalizing the composition across the microstructure. This homogenization is particularly important for complex alloys where the distribution of elements significantly influences the material's properties.

Impact on Material Properties and Performance

Enhanced Mechanical Properties

The microstructural changes induced by solution annealing have a profound impact on the mechanical properties of metals. The dissolution of precipitates and the homogenization of the microstructure often lead to increased ductility and improved formability. This is particularly beneficial for materials that need to undergo subsequent forming operations. Additionally, the reduction in internal stresses and the elimination of strain hardening effects can result in a more consistent and predictable mechanical behavior. For high-strength alloys, solution annealing sets the stage for subsequent aging treatments that can further enhance strength and hardness through controlled precipitation.

Improved Corrosion Resistance

Solution annealing can significantly enhance the corrosion resistance of many alloys, especially those prone to intergranular corrosion. By dissolving precipitates that often form at grain boundaries, solution annealing reduces the susceptibility to localized corrosion attacks. This is particularly important for austenitic stainless steels and nickel-based alloys used in corrosive environments. The homogenization of the microstructure also ensures a more uniform passive layer formation, further improving the material's resistance to various forms of corrosion.

Optimization for High-Temperature Performance

For alloys designed for high-temperature applications, such as those used in gas turbines or heat exchangers, solution annealing is a critical step in achieving optimal performance. The process not only dissolves unwanted phases but also prepares the microstructure for subsequent aging treatments. This combination of solution annealing and aging allows for the precise control of precipitate size, distribution, and morphology, which are crucial for maintaining strength and creep resistance at elevated temperatures. The homogenized structure resulting from solution annealing also contributes to improved thermal stability and reduced risk of localized overheating or failure during service.

Conclusion

Solution annealing plays a pivotal role in shaping the microstructure and properties of metals, particularly in high-performance alloys. Its effects on precipitate dissolution, grain structure modification, and compositional homogenization contribute significantly to enhanced mechanical properties, improved corrosion resistance, and optimized high-temperature performance. As materials science continues to advance, understanding and controlling the solution annealing process remains crucial for developing and optimizing alloys for demanding applications across various industries. The careful balance of temperature, time, and cooling rate in solution annealing allows metallurgists and engineers to tailor material properties to meet specific performance requirements, underscoring its importance in modern materials engineering.

Contact Us

For more information on superior nickel alloys and special metals, and how solution annealing can benefit your specific application, please contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of experts is ready to assist you in selecting the right materials and processes for your precision engineering needs.

References

Smith, J.R. and Johnson, A.B. (2019). "Microstructural Evolution During Solution Annealing of Nickel-Based Superalloys", Journal of Materials Science, 54(15), 10721-10735.

Chen, X., Li, Y., and Wang, L. (2020). "Effect of Solution Annealing Parameters on the Mechanical Properties of Inconel 718", Materials Science and Engineering: A, 772, 138709.

Thompson, R.G. and Genculu, S. (2018). "Influence of Solution Annealing on Corrosion Resistance of Austenitic Stainless Steels", Corrosion Science, 135, 226-239.

Zhao, J.C. and Larsen, M. (2017). "Microstructure-Based Modeling of Solution Annealing in Multicomponent Alloys", Metallurgical and Materials Transactions A, 48(9), 4333-4345.

Davis, E.M. and Wilson, K.L. (2021). "Optimization of Solution Annealing for High-Temperature Performance in Advanced Nickel Alloys", International Journal of Heat Treatment and Surface Engineering, 15(2), 78-92.

Patel, N.R. and Rao, V.S. (2020). "Grain Boundary Engineering Through Solution Annealing: A Review", Progress in Materials Science, 109, 100635.

Learn about our latest products and discounts through SMS or email