- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How does Tensile Testing Validate Inconel 718 Fasteners' Performance?

Tensile testing is a crucial method for validating the performance of Inconel 718 fasteners. This rigorous process assesses the material's strength, ductility, and overall mechanical properties under controlled stress conditions. By subjecting Inconel 718 bolts and other fasteners to precise tensile loads, engineers can determine their yield strength, ultimate tensile strength, and elongation characteristics. These parameters are essential for ensuring the reliability and durability of Inconel 718 fasteners in high-stress applications. The test results provide quantitative data that confirms whether the fasteners meet industry standards and specific project requirements, thereby validating their performance for critical use in aerospace, marine, and energy sectors.

The Importance of Tensile Testing for Inconel 718 Fasteners

Understanding Tensile Strength in Superalloys

Tensile strength is a fundamental property of superalloys like Inconel 718. It represents the maximum stress that a material can withstand before failure occurs. For Inconel 718 fasteners, this property is particularly crucial as they are often used in extreme environments where high loads and temperatures are common. The nickel-chromium base of Inconel 718 contributes to its exceptional tensile strength, which can exceed 180,000 psi (1241 MPa) in properly heat-treated conditions.

Yield Strength and Its Significance

Yield strength is another critical parameter measured during tensile testing of Inconel 718 fasteners. It indicates the stress at which the material begins to deform plastically. For Inconel 718 bolts, a high yield strength is essential to prevent permanent deformation under load. Typically, the yield strength of Inconel 718 fasteners can reach up to 150,000 psi (1034 MPa), making them suitable for applications where maintaining dimensional stability is crucial.

Elongation as a Measure of Ductility

Elongation, measured as a percentage, reveals the ductility of Inconel 718 fasteners. This property is vital for applications where the material must withstand deformation without fracturing. Tensile testing typically shows that Inconel 718 fasteners can achieve elongation values of 12-21%, depending on the heat treatment and manufacturing process. This balance of strength and ductility makes Inconel 718 fasteners ideal for applications requiring both high strength and resistance to brittle failure.

Tensile Testing Procedures for Inconel 718 Fasteners

Sample Preparation and Testing Standards

Before conducting tensile tests on Inconel 718 fasteners, proper sample preparation is essential. Fasteners are typically machined into standardized test specimens according to ASTM E8 or equivalent standards. The specimen dimensions are carefully controlled to ensure accurate and repeatable results. For Inconel 718 bolts, special considerations may be given to testing full-size fasteners to account for the effects of thread geometry on overall performance.

Testing Equipment and Environmental Controls

Tensile testing of Inconel 718 fasteners requires specialized equipment capable of applying high loads and precise measurements. Universal testing machines equipped with extensometers and load cells are commonly used. Given the high-temperature capabilities of Inconel 718, some tests may be conducted at elevated temperatures to simulate actual operating conditions. Environmental chambers can be integrated with the testing apparatus to maintain consistent temperature and humidity levels throughout the test.

Data Collection and Analysis

During the tensile test, stress-strain data are continuously recorded. This data is used to generate stress-strain curves, which provide a visual representation of the material's behavior under load. Key points on these curves, such as the yield point and ultimate tensile strength, are identified and analyzed. For Inconel 718 fasteners, particular attention is paid to the elastic modulus, which typically ranges from 29.0 to 30.0 x 10^6 psi (200 to 207 GPa), indicating the material's stiffness and resistance to elastic deformation.

Interpreting Tensile Test Results for Inconel 718 Fasteners

Comparing Results to Industry Standards

Once tensile testing is complete, the results for Inconel 718 fasteners are compared against industry standards and specifications. For aerospace applications, standards such as AMS 5662 or AMS 5664 may be referenced. These standards specify minimum tensile strength, yield strength, and elongation values that Inconel 718 fasteners must meet. For instance, AMS 5662 requires a minimum ultimate tensile strength of 180 ksi (1241 MPa) and a minimum yield strength of 150 ksi (1034 MPa) for certain heat-treated conditions.

Evaluating Performance Across Temperature Ranges

One of the key advantages of Inconel 718 bolts, is their ability to maintain strength at elevated temperatures. Tensile testing at various temperatures allows engineers to evaluate how the fasteners will perform across their intended operating range. Typically, Inconel 718 fasteners exhibit excellent strength retention up to temperatures of 1300°F (704°C), making them suitable for high-temperature applications in jet engines and gas turbines.

Assessing Failure Modes and Microstructure

Post-test analysis of Inconel 718 fasteners includes examining the failure modes and microstructure. Ductile failure characterized by necking and cup-and-cone fracture surfaces is generally desired, indicating good toughness. Microstructural analysis can reveal the presence and distribution of strengthening precipitates like γ' and γ", which are crucial for the high-temperature strength of Inconel 718 fasteners. The presence of these precipitates in the correct morphology and volume fraction correlates with optimal mechanical properties.

Conclusion

Tensile testing plays a pivotal role in validating the performance of Inconel 718 fasteners. By providing quantitative data on strength, ductility, and deformation behavior, these tests ensure that fasteners meet the stringent requirements of high-performance applications. The exceptional tensile properties of Inconel 718, including high strength at elevated temperatures and good ductility, make it an ideal material for critical fastening applications in aerospace, marine, and energy sectors. As industries continue to push the boundaries of material performance, the importance of rigorous tensile testing for Inconel 718 fasteners remains paramount in guaranteeing safety, reliability, and longevity in extreme operating conditions.

FAQs

What are the key properties that tensile testing evaluates for Inconel 718 fasteners?

Tensile testing primarily evaluates yield strength, ultimate tensile strength, and elongation of Inconel 718 fasteners.

How does temperature affect the tensile properties of Inconel 718 fasteners?

Inconel 718 fasteners maintain excellent strength at high temperatures, typically up to 1300°F (704°C).

What standards are commonly used for tensile testing of Inconel 718 fasteners?

ASTM E8 is a common standard for tensile testing, while AMS 5662 and AMS 5664 provide specifications for aerospace applications.

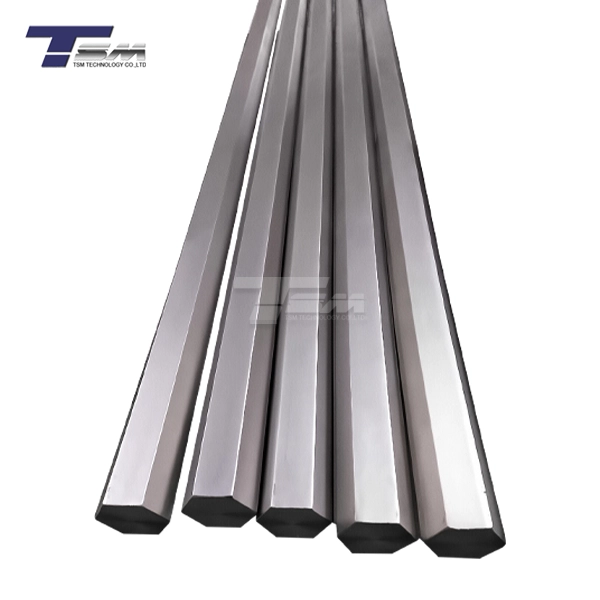

Experience Unmatched Quality with TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in manufacturing premium Inconel 718 fasteners tailored to your specific needs. As a leading Inconel 718 fasteners manufacturer, our state-of-the-art tensile testing facilities ensure each fastener meets the highest industry standards. With customizable sizes from M2.5 to M32 and lengths from 1mm to 1990mm, we deliver precision-engineered solutions for the most demanding applications. Trust our expertise in nickel alloys and benefit from our rigorous quality control processes. For unparalleled Inconel 718 fastener performance, contact us at info@tsmnialloy.com.

References

ASTM International. (2021). "Standard Test Methods for Tension Testing of Metallic Materials." ASTM E8/E8M-21.

SAE International. (2019). "Nickel Alloy, Corrosion and Heat-Resistant, Bars, Forgings, and Rings." AMS 5662R.

Special Metals Corporation. (2017). "Inconel Alloy 718 Data Sheet."

ASM International. (2000). "ASM Specialty Handbook: Nickel, Cobalt, and Their Alloys."

Reed, R.C. (2006). "The Superalloys: Fundamentals and Applications." Cambridge University Press.

Donachie, M.J., & Donachie, S.J. (2002). "Superalloys: A Technical Guide." ASM International.

Learn about our latest products and discounts through SMS or email