- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to Perform Non-Destructive Testing (NDT) on 718 Sheet Welds?

Non-Destructive Testing (NDT) on 718 sheet welds is crucial for ensuring the integrity and safety of welded structures. The process typically involves visual inspection, followed by more advanced techniques such as ultrasonic testing, radiographic testing, and liquid penetrant testing. Each method offers unique advantages in detecting surface and subsurface flaws without damaging the material. Proper NDT not only guarantees the quality of 718 sheet welds but also extends the lifespan of critical components in aerospace, energy, and industrial applications.

At TSM Technology, we specialize in providing high-quality 718 sheets and offer comprehensive NDT services to ensure the reliability of your welded structures. With our state-of-the-art facilities, experienced technicians, and commitment to excellence, we deliver superior alloy products that meet the most stringent industry standards. For inquiries about our 718 sheets or NDT services, please do not hesitate to contact us.

Understanding 718 Sheet Welds and Their Importance

Composition and Properties of 718 Sheet

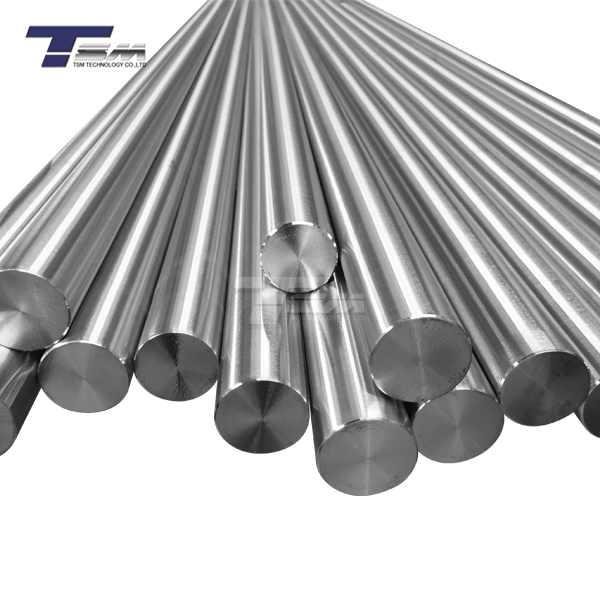

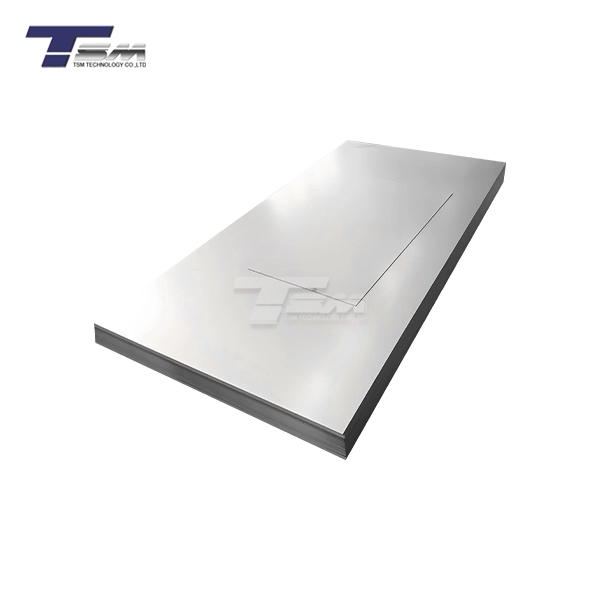

718 sheet, also known as Inconel 718, is a high-performance nickel-chromium alloy renowned for its exceptional strength and corrosion resistance. This precipitation-hardenable superalloy maintains its mechanical properties at temperatures up to 1300°F (704°C), making it ideal for demanding applications in aerospace, oil & gas, and power generation industries.

Key features of the 718 sheet include:

- High strength-to-weight ratio

- Excellent resistance to oxidation and corrosion

- Superior creep-rupture strength at elevated temperatures

- Good weldability and fabricability

- Stable mechanical properties across a wide temperature range

Critical Applications of 718 Sheet Welds

The unique properties of 718 sheet make it indispensable in various critical applications, including:

- Aerospace components (turbine disks, blades, shafts)

- Gas turbine engines

- Cryogenic storage tanks

- Nuclear reactor components

- Oil and gas equipment

- Chemical processing vessels

In these applications, the integrity of 718 sheet welds is paramount to ensure the safety, reliability, and longevity of the structures.

Challenges in Welding 718 Sheet

While the 718 sheet exhibits good weldability, certain challenges may arise during the welding process:

- Susceptibility to hot cracking

- Formation of undesirable phases in the heat-affected zone

- Potential for stress corrosion cracking in certain environments

- Need for precise control of heat input and cooling rates

These challenges underscore the importance of proper welding techniques and rigorous NDT to ensure the quality and reliability of 718 sheet welds.

Non-Destructive Testing Methods for 718 Sheet Welds

Visual Inspection: The First Line of Defense

Visual inspection is the most fundamental and cost-effective NDT method for 718 sheet welds. Trained inspectors examine the weld surface for visible defects such as:

- Cracks

- Porosity

- Undercut

- Incomplete fusion

- Improper weld profile

While visual inspection can detect surface flaws, it has limitations in identifying subsurface defects. Therefore, it's typically used in conjunction with other NDT methods for comprehensive weld evaluation.

Ultrasonic Testing: Detecting Subsurface Flaws

Ultrasonic testing (UT) is a highly effective method for detecting internal defects in 718 sheet welds. This technique uses high-frequency sound waves to penetrate the material and reflect off discontinuities. Benefits of UT include:

- Ability to detect subsurface flaws

- Precise location and sizing of defects

- No radiation hazards

- Suitable for thick sections

Advanced UT techniques such as phased array and time-of-flight diffraction (TOFD) offer enhanced capabilities for 718 sheet weld inspection.

Radiographic Testing: Comprehensive Weld Imaging

Radiographic testing (RT) provides a visual representation of the internal structure of 718 sheet welds. X-rays or gamma rays are used to create an image of the weld on film or digital detectors. RT is particularly useful for detecting:

- Porosity

- Inclusions

- Lack of fusion

- Internal cracks

While RT offers excellent detection capabilities, it requires proper safety measures due to the risks of radiation exposure.

Advanced NDT Techniques for 718 Sheet Welds

Liquid Penetrant Testing: Enhancing Surface Flaw Detection

Liquid penetrant testing (PT) is a highly sensitive method for detecting surface-breaking defects in 718 sheet welds. The process involves:

- Cleaning the weld surface

- Applying a penetrant liquid

- Removing excess penetrant

- Applying a developer to draw out trapped penetrant

- Inspecting under proper lighting conditions

PT is particularly effective for detecting fine surface cracks that may be missed during visual inspection.

Eddy Current Testing: Rapid Surface and Near-Surface Inspection

Eddy current testing (ET) uses electromagnetic induction to detect surface and near-surface flaws in 718 sheet welds. This method offers several advantages:

- No contact required with the weld surface

- Rapid inspection speeds

- Ability to detect small cracks and other discontinuities

- Suitable for automated inspection systems

ET is particularly useful for inspecting complex geometries and detecting fatigue cracks in 718 sheet welds.

Phased Array Ultrasonic Testing: Advanced Flaw Detection and Sizing

Phased Array Ultrasonic Testing (PAUT) is an advanced form of UT that offers enhanced capabilities for 718 sheet weld inspection:

- Improved detection of small and oriented flaws

- Better characterization and sizing of defects

- Ability to create detailed images of the weld internal structure

- Reduced inspection times compared to conventional UT

PAUT is particularly valuable for inspecting complex weld geometries and thick sections in 718 sheet applications.

Conclusion

Performing Non-Destructive Testing on 718 sheet welds is crucial for ensuring the integrity and reliability of critical components in various industries. By employing a combination of visual inspection, ultrasonic testing, radiographic testing, and advanced techniques like liquid penetrant testing and phased array UT, manufacturers and end-users can detect and address potential flaws before they lead to catastrophic failures. As technology continues to advance, NDT methods for 718 sheet welds will become even more precise and efficient, further enhancing the safety and performance of structures made with this remarkable alloy.

FAQs

What makes 718 sheet ideal for high-temperature applications?

718 sheet maintains its mechanical properties at temperatures up to 1300°F (704°C), thanks to its precipitation-hardenable nickel-chromium composition.

How often should NDT be performed on 718 sheet welds?

The frequency depends on the application, but typically includes initial post-weld inspection and periodic in-service inspections as per industry standards.

Can TSM Technology provide custom 718 sheet products?

Yes, we offer customization and processing support for 718 sheets, including various surface treatments and thicknesses ranging from 0.5 to 50 mm.

Choose TSM Technology for Premium 718 Sheet and NDT Services

TSM Technology is your trusted partner for high-quality 718 sheets and comprehensive NDT services. With our state-of-the-art facilities, including 3 factories, 8 production lines, and over 100 machines, we deliver superior alloy products that meet ASTM B670, ASME SB670, and AMS 5596 standards. Our expertise in hot-rolled, cold-rolled, and annealed finishes, combined with customization options and rigorous quality control, ensures that you receive 718 sheets tailored to your specific needs. For inquiries or to request a free sample, contact us at info@tsmnialloy.com.

References

American Society for Nondestructive Testing. (2021). Handbook of Nondestructive Evaluation, 4th Edition.

ASM International. (2018). ASM Handbook, Volume 17: Nondestructive Evaluation of Materials.

Special Metals Corporation. (2019). INCONEL alloy 718 Technical Data Sheet.

Aerospace Materials Specification. (2020). AMS 5596: Nickel Alloy, Corrosion and Heat-Resistant, Sheet, Strip, and Plate.

Journal of Materials Engineering and Performance. (2022). "Advanced NDT Techniques for Superalloy Weld Inspection."

International Journal of Pressure Vessels and Piping. (2021). "Reliability Assessment of Inconel 718 Welded Joints Using Non-Destructive Testing Methods."

Learn about our latest products and discounts through SMS or email