- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Eddy Current Testing Works?

When it comes to ensuring the integrity of high-performance materials, such as those used in precision engineering, eddy current testing (ECT) stands out as a powerful, non-destructive evaluation method. This technique is particularly vital in industries that rely on superior alloys—specialized metals designed to withstand extreme conditions, such as corrosion, heat, and pressure. But how exactly does eddy current testing work? In essence, it uses electromagnetic principles to detect flaws, measure thickness, and assess material properties without damaging the component. By inducing electric currents in conductive materials, ECT detects defects such as cracks or voids, thereby ensuring the reliability of critical parts. This makes it an indispensable tool for manufacturers and suppliers of advanced materials, including those crafting nickel-based alloys for global industries.

The Science Behind Eddy Current Testing

Eddy current testing is a fascinating blend of physics and engineering, offering a non-invasive way to inspect conductive materials. To truly appreciate its value, it's worth delving into the core principles, the equipment involved, and the types of defects it can detect, especially in the context of advanced alloys used in demanding applications.

The Electromagnetic Principles at Play

At the heart of eddy current testing lies electromagnetic induction, a phenomenon discovered by Michael Faraday in the 19th century. When an alternating current (AC) flows through a coil, it generates a fluctuating magnetic field. If this coil is brought near a conductive material, such as a superior alloy, the magnetic field induces circular electric currents - known as eddy currents - within the material. These currents, in turn, create their secondary magnetic field, which interacts with the original field from the coil. Any changes in the material, such as cracks, corrosion, or variations in conductivity, disrupt the flow of eddy currents, altering the magnetic field. These alterations are detected by sensitive instruments, providing insights into the material's condition.

The Equipment That Makes It Possible

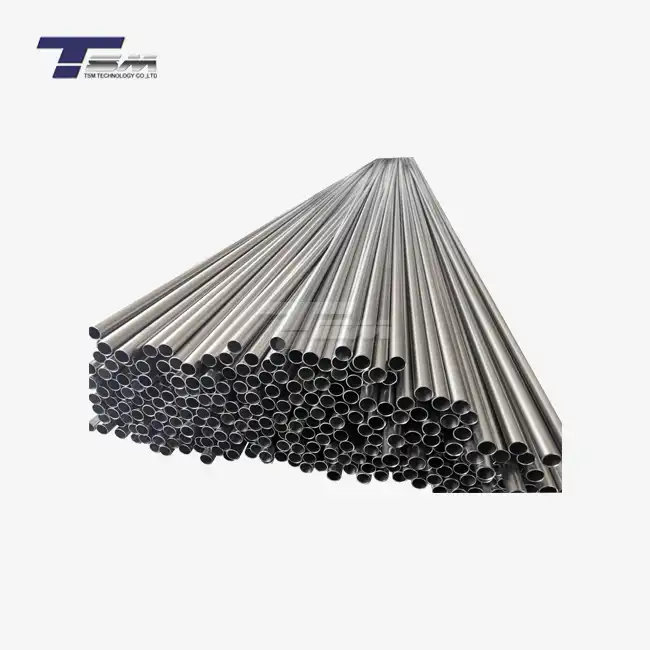

Eddy current testing relies on specialized equipment to achieve precise results. The core component is the probe, which houses the coil responsible for generating the magnetic field. Probes come in various designs, such as surface probes for flat components or encircling coils for cylindrical parts like tubes or rods. The probe is connected to an eddy current instrument, a sophisticated device that generates the alternating current, measures the resulting signals, and displays the data. Modern instruments often include digital displays and software for detailed analysis, making it easier to interpret results. For industries working with superior alloys, calibration standards are critical, as these materials often have unique electrical and magnetic properties that require tailored settings for accurate testing.

Defects and Properties It Can Detect

One of the reasons eddy current testing is so widely used is its versatility in identifying a range of defects and material characteristics. Surface and near-surface flaws, such as cracks, pits, and inclusions, are easily detected, making it ideal for inspecting components made from advanced alloys. Additionally, ECT can measure material thickness, which is crucial for assessing corrosion or erosion in pipes and vessels. It can also evaluate conductivity, helping to verify the composition of alloys or detect heat treatment variations. For manufacturers of high-performance materials, this ability to non-destructively assess both defects and properties ensures that only the highest-quality components reach the market, safeguarding reliability in critical applications.

The Eddy Current Testing Process

Understanding how eddy current testing works in practice is key to appreciating its role in quality assurance, especially for industries dealing with specialized metals. The process involves meticulous preparation, execution, and analysis, each step designed to maximize accuracy and reliability without compromising the integrity of the tested components.

Preparing the Material for Testing

Before testing begins, the material must be properly prepared to ensure accurate results. This is particularly important for superior alloys, which often have complex compositions and surface finishes. The surface of the component needs to be clean and free from contaminants like oil, dirt, or oxide layers, as these can interfere with the electromagnetic signals. In some cases, light sanding or chemical cleaning may be necessary, though care must be taken not to alter the material's properties. Additionally, the geometry of the component - whether it's a flat plate, a tube, or a complex machined part - must be considered, as it influences the choice of probe and testing parameters. Calibration is also essential, using reference standards that match the alloy's characteristics to establish a baseline for defect detection.

Conducting the Test Step by Step

Once the material is prepared, the actual testing process begins. The operator positions the probe close to the surface of the component, ensuring consistent contact or a uniform lift-off distance, depending on the probe type. As the alternating current flows through the coil, the induced eddy currents penetrate the material, typically to a depth determined by the frequency of the current and the material's conductivity. Lower frequencies allow deeper penetration, while higher frequencies are better for detecting surface flaws. The instrument continuously monitors the impedance of the coil, which changes in response to variations in the eddy current flow caused by defects or material properties. The operator may scan the probe across the surface manually or use automated systems for larger components, ensuring comprehensive coverage.

Interpreting the Results

The final step in the process is interpreting the data collected during the test. Modern eddy current instruments display results in various formats, such as impedance plane diagrams or amplitude-phase plots, which trained operators analyze to identify anomalies. For example, a crack might appear as a distinct signal deviation, while corrosion could show as a gradual change in impedance. In industries working with advanced alloys, interpretation often requires a deep understanding of the material's unique properties, as factors like grain structure or alloying elements can influence the signals. Advanced software can assist by filtering noise and highlighting potential defects, but human expertise remains crucial, especially for complex components. This meticulous analysis ensures that only flawless parts proceed to the next stage of production or application.

Advantages of Eddy Current Testing for Specialized Metals

Eddy current testing offers distinct benefits, particularly when applied to high-performance materials like superior alloys. Its non-destructive nature, precision, and adaptability make it an invaluable tool for manufacturers and suppliers aiming to uphold stringent quality standards in global markets.

Non-Destructive and Efficient Evaluation

One of the most significant advantages of eddy current testing is its non-destructive nature, meaning components can be inspected without being damaged or altered. This is especially critical for industries working with advanced alloys, where components are often expensive to produce and intended for critical applications, such as aerospace or chemical processing. Unlike destructive methods that require cutting or breaking parts, ECT allows for 100% inspection of production batches, ensuring every piece meets quality standards. Additionally, the process is relatively fast, with automated systems capable of scanning large volumes of material in a short time, boosting efficiency without sacrificing accuracy.

Precision in Detecting Flaws

Eddy current testing excels in detecting minute flaws, making it ideal for inspecting superior alloys where even tiny defects can compromise performance. Surface cracks as small as 0.5 mm and subsurface flaws up to a few millimeters deep can be identified, depending on the material and testing parameters. This precision is vital for alloys like nickel-based materials, which are often used in environments where failure is not an option, such as high-pressure reactors or jet engines. The ability to detect flaws early in the production process also reduces waste, as defective parts can be identified and addressed before further value is added through machining or assembly.

Versatility Across Alloy Types

Another key benefit of eddy current testing is its adaptability to a wide range of conductive materials, including the diverse family of superior alloys. Whether it's a corrosion-resistant alloy, a high-temperature material, or a specialized metal with unique magnetic properties, ECT can be tailored to suit the specific characteristics of the alloy. By adjusting the frequency, probe design, and calibration standards, manufacturers can ensure accurate testing across different alloy compositions and forms, from sheets and plates to tubes and forgings. This versatility is particularly valuable for global suppliers, who must meet the varied needs of precision engineering industries worldwide, delivering materials that consistently perform under extreme conditions.

Conclusion

Eddy current testing is a cornerstone of quality assurance in industries that rely on high-performance materials, offering a non-destructive, precise, and efficient way to ensure the integrity of components. By harnessing electromagnetic principles, this method detects flaws, measures properties, and verifies the reliability of specialized metals, making it indispensable for manufacturers and suppliers of advanced alloys. Its ability to adapt to various alloy types and deliver rapid, accurate results underscores its value in meeting the rigorous demands of global markets. For those in precision engineering, understanding this technique is key to appreciating the quality behind the materials they use.

Contact Us

For more information about superior nickel alloys and special metals that can be evaluated using eddy current testing, please contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of experts is ready to assist you with your material needs and testing requirements.

References

"Non-Destructive Testing Handbook, Volume 5: Electromagnetic Testing" - American Society for Nondestructive Testing, 2004.

"Eddy Current Testing: Principles and Applications" - John C. Drury, NDT Publishing, 2010.

"Electromagnetic Nondestructive Evaluation: Theory and Practice" - edited by K. Miya, IOS Press, 2007.

"Introduction to Electromagnetic Nondestructive Testing" - H.L. Libby, Wiley-Interscience, 1971.

"Eddy Current Testing Technology" - V.S. Cecco, G. Van Drunen, and F.L. Sharp, Atomic Energy of Canada Limited, 1987.

"Advances in Electromagnetic Testing Techniques" - edited by R.E. Beissner, Springer, 1999.

Learn about our latest products and discounts through SMS or email