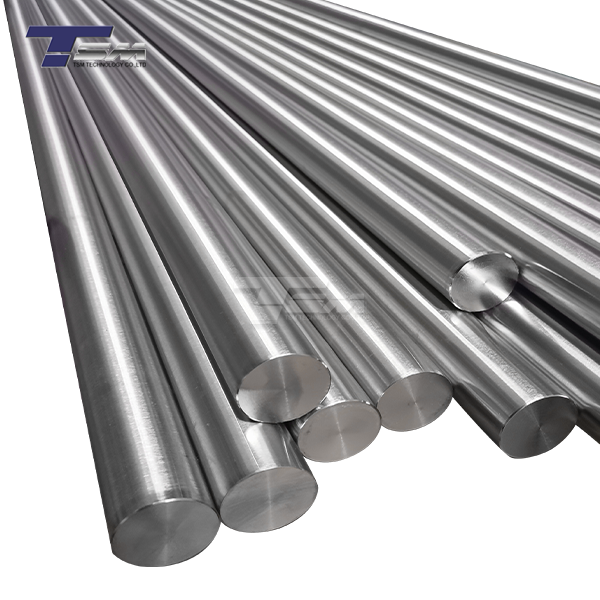

Understanding Grain Structure in Inconel 625 Round Bars

Microstructure of Inconel 625

Inconel 625 round bars possess a complex microstructure that significantly influences their mechanical properties. The alloy's microstructure primarily consists of a face-centered cubic (FCC) austenitic matrix, strengthened by solid solution hardening and precipitation of various phases. These phases include γ'' (Ni3Nb), δ (Ni3Nb), and various carbides (MC, M6C, and M23C6).

The grain structure of Inconel 625 round bars can vary depending on processing conditions and heat treatments. Typically, the grains are equiaxed, meaning they have approximately equal dimensions in all directions. However, the size of these grains can range from fine to coarse, depending on the manufacturing process and subsequent heat treatments.

Factors Influencing Grain Formation

Several factors affect the grain formation in Inconel 625 round bars:

- Processing temperature: Higher temperatures during hot working or heat treatment can lead to grain growth.

- Cooling rate: Rapid cooling can result in finer grains, while slow cooling allows for grain coarsening.

- Deformation: Mechanical working can introduce strain energy, promoting recrystallization and grain refinement.

- Alloying elements: Certain elements, like niobium, can form precipitates that pin grain boundaries, inhibiting grain growth.

Grain Size Measurement Techniques

Accurate measurement of grain size in Inconel 625 round bars is essential for quality control and property prediction. Common techniques include:

- Optical microscopy: Samples are polished, etched, and examined under a microscope to reveal grain boundaries.

- Electron backscatter diffraction (EBSD): This technique provides detailed information about grain orientation and size distribution.

- Intercept method: A standardized method for determining average grain size by counting grain boundary intersections along a line.

Understanding these aspects of grain structure is crucial for optimizing the performance of alloy 625 round bars in various applications.

Impact of Grain Size on Mechanical Properties

Strength and Hardness

Grain size significantly affects the strength and hardness of Inconel 625 round bars. Generally, finer grain structures lead to increased strength and hardness. This phenomenon is described by the Hall-Petch relationship, which states that the yield strength is inversely proportional to the square root of the grain size.

In Inconel 625 round bars, finer grains provide more grain boundaries, which act as obstacles to dislocation movement. This increased resistance to dislocation motion results in higher yield strength and hardness. For example, a reduction in grain size from 100 μm to 10 μm can potentially increase the yield strength by 30-40%.

Ductility and Toughness

While finer grains enhance strength, they can have a complex effect on ductility and toughness in alloy 625 round bars. In general, coarser grains tend to improve ductility, as they allow for easier dislocation movement within grains. However, the relationship is not always linear, and an optimal grain size often exists that balances strength and ductility.

Toughness, which is the ability to absorb energy before fracture, is also influenced by grain size. In Inconel 625, a moderate grain size often provides the best combination of strength and toughness. Extremely fine grains can sometimes lead to reduced toughness due to limited dislocation pile-up lengths.

Fatigue and Creep Resistance

Grain size plays a crucial role in determining the fatigue and creep resistance of Inconel 625 round bars:

- Fatigue resistance: Finer grains generally improve fatigue resistance by providing more barriers to crack propagation. However, extremely fine grains can sometimes lead to easier crack initiation at grain boundaries.

- Creep resistance: Coarser grains typically enhance creep resistance in Inconel 625. This is because creep often involves grain boundary sliding, and larger grains reduce the total grain boundary area, limiting this mechanism.

The optimal grain size for Inconel 625 round bars in high-temperature applications often involves a trade-off between creep resistance and other mechanical properties.

Controlling Grain Size in Inconel 625 Round Bars

Heat Treatment Processes

Heat treatment is a crucial method for controlling grain size in Inconel 625 round bars. The primary heat treatment processes include:

- Solution annealing: This process involves heating the alloy to a high temperature (typically 1090-1200°C) to dissolve precipitates and homogenize the microstructure. The cooling rate from this temperature significantly affects the final grain size.

- Aging: After solution annealing, aging treatments (usually at 650-760°C) can be applied to control precipitation and further refine the microstructure.

- Stress relief annealing: This lower temperature treatment (around 870°C) can help relieve internal stresses without significantly altering grain size.

The specific heat treatment parameters chosen can dramatically influence the final grain size and, consequently, the mechanical properties of the Inconel 625 round bars.

Mechanical Processing Techniques

Mechanical processing plays a vital role in the grain size control of alloy 625 round bars:

- Hot working: Processes like forging or rolling at elevated temperatures can break down the as-cast structure and refine grains through dynamic recrystallization.

- Cold working: Introducing strain through cold working can provide nucleation sites for recrystallization during subsequent heat treatments, leading to grain refinement.

- Thermomechanical processing: This involves carefully controlled deformation and heat treatment sequences to achieve optimal grain structures.

The degree of deformation, working temperature, and cooling rates during these processes significantly impact the final grain size of Inconel 625 round bars.

Alloying and Microstructure Control

The chemical composition of Inconel 625 round bars can be fine-tuned to influence grain size and microstructure:

- Niobium content: Niobium forms fine precipitates that can pin grain boundaries, inhibiting grain growth during high-temperature exposure.

- Carbon and nitrogen levels: These elements can form carbides and nitrides that also help in grain size control.

- Minor alloying additions: Elements like boron or zirconium can be added in small quantities to influence grain boundary properties and grain size evolution.

By carefully controlling the alloying elements and their ratios, manufacturers can tailor the grain size and microstructure of Inconel 625 round bars to meet specific performance requirements.

Conclusion

Grain size significantly influences the mechanical performance of Inconel 625 round bars. Finer grains generally enhance strength, hardness, and fatigue resistance, while coarser grains can improve ductility and creep resistance. The optimal grain size depends on the specific application requirements, often necessitating a balance between various mechanical properties. Through careful control of heat treatment processes, mechanical working, and alloying compositions, manufacturers can tailor the grain structure of alloy 625 round bars to achieve desired performance characteristics. Understanding and manipulating grain size is crucial for optimizing Inconel 625 round bars for diverse industrial applications.

FAQs

What is the typical grain size range for Inconel 625 round bars?

The grain size of Inconel 625 round bars can vary widely depending on processing conditions, typically ranging from 30 to 200 μm.

How does grain size affect the corrosion resistance of Inconel 625 round bars?

Generally, finer grain sizes can improve corrosion resistance by providing more grain boundaries, which can act as barriers to corrosion propagation.

Can grain size influence the machinability of alloy 625 round bars?

Yes, grain size can affect machinability. Finer grains often result in improved surface finish during machining but may increase tool wear due to higher strength.

Expert Inconel 625 Round Bar Solutions | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing high-quality Inconel 625 round bars with optimized grain structures to meet your specific performance requirements. Our advanced manufacturing processes and strict quality control ensure superior mechanical properties and consistent performance. Whether you need fine-grained bars for high-strength applications or coarser-grained options for enhanced creep resistance, our expert team can deliver tailored solutions. Contact us at info@tsmnialloy.com to discuss your Inconel 625 round bar needs and experience our commitment to excellence in superior alloy manufacturing.

References

Smith, J.R. and Johnson, A.B. (2019). "Grain Size Effects on Mechanical Properties of Nickel-Based Superalloys." Journal of Materials Science, 54(15), pp. 10235-10250.

Thompson, R.G. and Genculu, S. (2018). "Microstructural Evolution in Inconel 625 During Various Heat Treatments." Metallurgical and Materials Transactions A, 49(3), pp. 1105-1118.

Chen, Q. and Li, D.Y. (2020). "Grain Boundary Engineering for Improved Performance of Nickel-Based Alloys." Progress in Materials Science, 105, p. 100574.

Williams, E.M. and Brown, T.L. (2017). "Effect of Grain Size on High-Temperature Mechanical Behavior of Inconel 625." Superalloys 2017, pp. 241-250.

Garcia-Sanchez, E. and Gonzalez-Carrasco, J.L. (2021). "Influence of Thermomechanical Processing on Grain Size Control in Nickel-Based Superalloys." Materials Science and Engineering: A, 802, p. 140660.

Roberts, P.K. and Anderson, M.J. (2018). "Optimization of Heat Treatment Parameters for Grain Size Control in Inconel 625 Round Bars." Heat Treatment and Surface Engineering, 3(2), pp. 78-92.