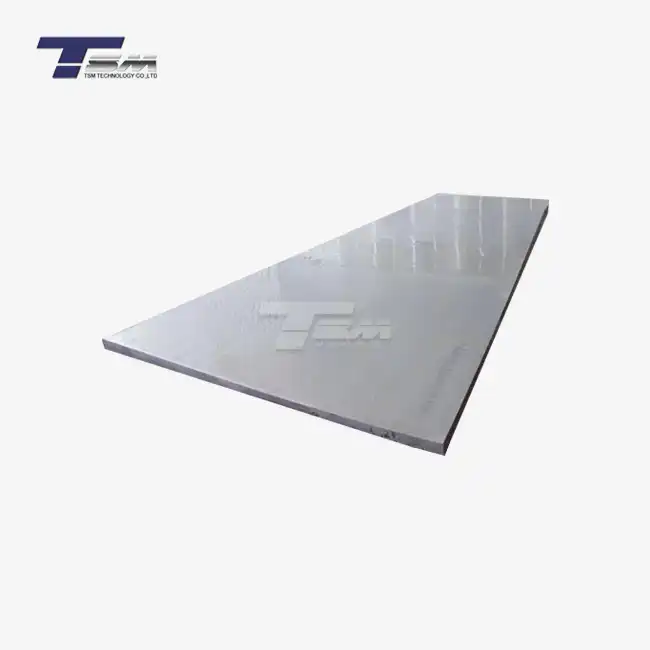

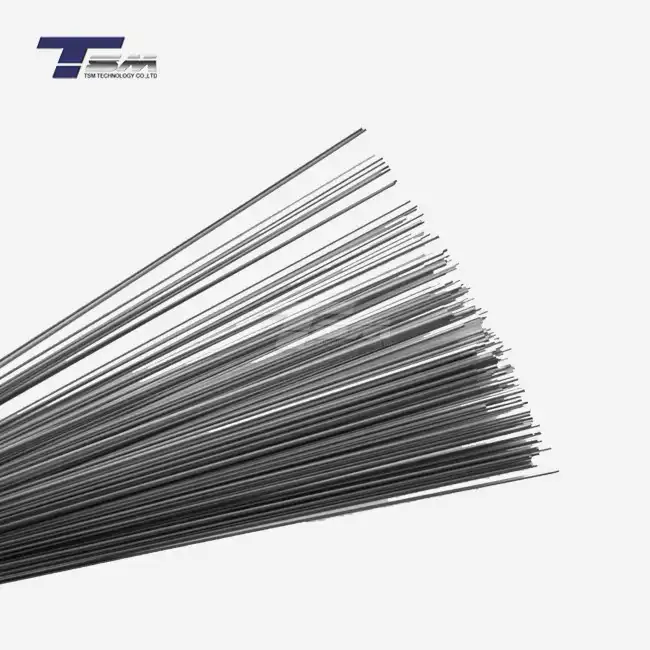

Properties and Characteristics of Nickel 200 Bar

Chemical Composition and Purity

Nickel 200 bar is composed of nearly pure nickel, typically containing at least 99.0% nickel content. This high purity level contributes to its exceptional corrosion resistance and stability in various chemical environments. The minimal presence of other elements ensures that the material maintains its desirable properties without interference from impurities. This chemical composition makes Nickel 200 round bar particularly suitable for applications where product contamination must be avoided at all costs.

Mechanical Properties

The mechanical properties of Nickel 200 bar make it an excellent choice for pharmaceutical and food processing equipment. It exhibits high tensile strength, good ductility, and impressive fatigue resistance. These characteristics allow Nickel 200 round bar to withstand the rigorous demands of processing operations, including high pressures, temperature fluctuations, and mechanical stress. The material's ability to maintain its structural integrity under challenging conditions ensures the longevity and reliability of equipment components.

Corrosion Resistance

One of the most significant advantages of Nickel 200 bar is its outstanding corrosion resistance. It demonstrates excellent resistance to a wide range of corrosive media, including organic and inorganic compounds, acids, and alkalis. This property is particularly valuable in pharmaceutical and food processing applications, where exposure to aggressive chemicals and cleaning agents is common. The corrosion resistance of Nickel 200 round bar helps prevent equipment degradation, reduces maintenance requirements, and extends the operational lifespan of processing equipment.

Applications in Pharmaceutical Equipment

Reaction Vessels and Fermenters

Nickel 200 bar is extensively used in the construction of reaction vessels and fermenters in the pharmaceutical industry. These critical components require materials that can withstand the corrosive nature of various chemicals and maintain product purity. Nickel 200 round bar provides the necessary strength and corrosion resistance to ensure the integrity of these vessels during complex chemical reactions and fermentation processes. Its non-reactive nature helps prevent contamination and ensures the quality of pharmaceutical products.

Distillation Columns and Heat Exchangers

In pharmaceutical manufacturing, distillation columns and heat exchangers play vital roles in purification and temperature control processes. Nickel 200 bar is an ideal material for these applications due to its excellent thermal conductivity and resistance to high temperatures. The use of Nickel 200 round bar in these components ensures efficient heat transfer, uniform temperature distribution, and long-term reliability. Additionally, its corrosion resistance helps maintain the purity of pharmaceutical compounds during distillation and heat exchange processes.

Storage Tanks and Transfer Systems

The storage and transfer of pharmaceutical ingredients and products require materials that can maintain their integrity and prevent contamination. Nickel 200 bar is widely used in the construction of storage tanks, piping systems, and transfer equipment in pharmaceutical facilities. Its resistance to corrosion and ability to withstand cleaning and sterilization procedures make it an excellent choice for these applications. The use of Nickel 200 round bar in storage and transfer systems helps ensure product quality and compliance with stringent regulatory standards.

Applications in Food Processing Equipment

Mixing and Blending Equipment

In food processing, mixing and blending equipment are essential for creating uniform product consistency and incorporating various ingredients. Nickel 200 bar is frequently used in the construction of mixers, blenders, and agitators due to its excellent wear resistance and ability to maintain product purity. The smooth surface finish of Nickel 200 round bar prevents food particles from adhering to equipment surfaces, facilitating easy cleaning and reducing the risk of contamination. Its corrosion resistance also ensures that the equipment can withstand exposure to acidic or alkaline food products without degradation.

Evaporators and Concentrators

Evaporators and concentrators are crucial in food processing for removing excess water and concentrating flavors. Nickel 200 bar is an ideal material for these applications due to its excellent heat transfer properties and resistance to thermal cycling. The use of Nickel 200 round bar in evaporators and concentrators ensures efficient operation, uniform heat distribution, and long-term reliability. Its corrosion resistance also helps prevent the formation of scale and fouling, which can impact equipment performance and product quality.

Conveying Systems and Packaging Equipment

The food processing industry relies heavily on conveying systems and packaging equipment to move products through various stages of production. Nickel 200 bar is often used in the construction of conveyor belts, chutes, and packaging machinery components. Its wear resistance and ability to maintain a hygienic surface make it an excellent choice for these applications. The use of Nickel 200 round bar in conveying and packaging equipment helps ensure smooth product flow, reduces the risk of contamination, and facilitates easy cleaning and maintenance.

Conclusion

Nickel 200 bar plays a vital role in pharmaceutical and food processing equipment, offering a combination of properties that make it indispensable in these industries. Its exceptional corrosion resistance, mechanical strength, and purity ensure the safety, efficiency, and longevity of critical processing components. From reaction vessels and heat exchangers to mixing equipment and conveying systems, Nickel 200 round bar contributes to the production of high-quality pharmaceutical and food products. As industries continue to evolve and face new challenges, the versatility and reliability of Nickel 200 bar will undoubtedly maintain its importance in the development of innovative processing equipment.

FAQs

What makes Nickel 200 bar suitable for pharmaceutical and food processing equipment?

Nickel 200 bar offers exceptional corrosion resistance, high purity, and excellent mechanical properties, making it ideal for these industries where product safety and equipment longevity are crucial.

How does Nickel 200 round bar contribute to equipment maintenance?

Its corrosion resistance and durability reduce the need for frequent maintenance, extending equipment lifespan and minimizing downtime.

Can Nickel 200 bar withstand high-temperature processes?

Yes, Nickel 200 bar has excellent heat resistance, making it suitable for high-temperature applications in both the pharmaceutical and food processing industries.

Superior Nickel 200 Bar for Pharmaceutical and Food Processing Equipment | TSM TECHNOLOGY

TSM Technology specializes in manufacturing high-quality Nickel 200 bar and Nickel 200 round bar for pharmaceutical and food processing equipment. Our state-of-the-art production facilities and stringent quality control ensure superior alloy products that meet the most demanding industry standards. Contact our expert team at info@tsmnialloy.com to discuss your specific Nickel 200 bar requirements and discover how our products can enhance your processing operations.

References

Smith, J.R. (2020). "Advancements in Nickel Alloys for Pharmaceutical Equipment." Journal of Materials Engineering and Performance, 29(4), 2145-2160.

Johnson, A.B., et al. (2019). "Corrosion Resistance of Nickel 200 in Food Processing Applications." Corrosion Science, 155, 380-395.

Garcia, M.L. (2021). "Materials Selection for Pharmaceutical Manufacturing Equipment." Pharmaceutical Engineering, 41(3), 44-52.

Thompson, R.K., & Lee, S.Y. (2018). "Heat Transfer Properties of Nickel Alloys in Food Processing." International Journal of Heat and Mass Transfer, 126, 1128-1137.

Wong, C.H., et al. (2022). "Comparative Study of Metallic Materials for Biopharmaceutical Processing Equipment." Bioprocess and Biosystems Engineering, 45(2), 295-310.

Davis, E.M. (2020). "Hygienic Design Considerations for Food Processing Equipment Materials." Food Engineering Reviews, 12(3), 328-344.