- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to Fabricate and Weld Hastelloy C276 Round Bar for High-Performance Applications?

Fabricating and welding Hastelloy C276 round bar for high-performance applications requires specialized techniques and careful attention to detail. To achieve optimal results, start by selecting high-quality Hastelloy C276 material from a reputable supplier. Employ proper machining methods, including using sharp carbide tools and maintaining low cutting speeds to prevent work hardening. For welding, utilize gas tungsten arc welding (GTAW) or gas metal arc welding (GMAW) processes with appropriate filler metals. Maintain strict temperature control during welding to prevent hot cracking. Post-weld heat treatment may be necessary to restore corrosion resistance. Always follow industry standards and manufacturer guidelines throughout the fabrication and welding process to ensure the final product meets high-performance requirements.

Preparing Hastelloy C276 Round Bar for Fabrication

Material Selection and Quality Assurance

When preparing Hastelloy C276 round bar for fabrication, it's crucial to start with high-quality material. Ensure that the Hastelloy rod meets the required specifications, such as ASTM B574 or ASME SB574. Perform thorough quality checks, including dimensional verification and surface inspection. Some suppliers offer ultrasonic testing (UT) or radiographic testing (RT) to guarantee internal integrity. Proper material selection lays the foundation for successful fabrication and welding processes.

Surface Preparation Techniques

Before initiating fabrication, proper surface preparation is essential. Begin by cleaning the Hastelloy C276 round bar to remove any contaminants, oils, or debris. Depending on the application, you may need to perform surface treatments such as pickling or passivation to enhance corrosion resistance. For precision applications, consider surface finishing techniques like polishing or grinding to achieve the desired surface roughness and dimensional accuracy.

Cutting and Machining Considerations

Cutting and machining Hastelloy C276 require special considerations due to the material's work-hardening properties. Use sharp, carbide-tipped tools and maintain low cutting speeds to prevent excessive heat generation. Employ ample coolant to dissipate heat and prolong tool life. When machining, take light cuts and use positive rake angles to minimize work hardening. For complex shapes, consider using computer numerical control (CNC) machining to achieve precise dimensions and intricate features.

Welding Techniques for Hastelloy C276 Round Bar

Recommended Welding Processes

When welding Hastelloy C276 round bar, gas tungsten arc welding (GTAW) and gas metal arc welding (GMAW) are the preferred methods. GTAW, also known as TIG welding, offers excellent control and is ideal for thin sections and precision work. GMAW, or MIG welding, provides higher deposition rates and is suitable for thicker sections. Both processes can produce high-quality welds when performed correctly. For optimal results, use ERNiCrMo-4 filler metal, which closely matches the composition of Hastelloy C276.

Welding Parameter Optimization

Optimizing welding parameters is crucial for achieving high-quality welds in Hastelloy round bar. Maintain a low heat input to minimize the risk of hot cracking and preserve the material's corrosion resistance. Use direct current electrode negative (DCEN) polarity for GTAW and direct current electrode positive (DCEP) for GMAW. Control interpass temperature, typically keeping it below 150°C (302°F) to prevent precipitation of detrimental phases. Employ proper shielding gas, such as argon or argon-helium mixtures, to protect the weld pool from atmospheric contamination.

Post-Weld Heat Treatment and Inspection

After welding Hastelloy C276 round bar, post-weld heat treatment (PWHT) may be necessary to restore corrosion resistance and relieve residual stresses. The typical PWHT for Hastelloy C276 involves solution annealing at temperatures between 1120°C to 1180°C (2050°F to 2160°F), followed by rapid cooling. Conduct thorough post-weld inspections, including visual examination, radiographic testing, and dye penetrant testing to ensure weld quality. For critical applications, consider performing corrosion testing to verify the integrity of the welded joint.

Ensuring High Performance in Fabricated Hastelloy C276 Components

Quality Control Measures

Implementing rigorous quality control measures is essential for ensuring high performance in fabricated Hastelloy C276 components. Establish a comprehensive quality management system that covers all aspects of the fabrication process, from material receipt to final inspection. Perform regular calibration of measuring instruments and welding equipment. Conduct in-process inspections at critical stages of fabrication to catch and address any issues early. Maintain detailed documentation of all fabrication and welding procedures, including material certifications, welding parameters, and inspection results.

Performance Testing and Validation

To guarantee that fabricated Hastelloy C276 components and Hastelloy round bar meet high-performance requirements, conduct thorough performance testing and validation. Depending on the application, this may include mechanical testing (e.g., tensile strength, hardness), corrosion resistance testing (e.g., pitting resistance, stress corrosion cracking), and fatigue testing. For components intended for extreme environments, consider simulating service conditions through accelerated aging tests or exposure to corrosive media. Validate the performance against industry standards and customer specifications to ensure compliance.

Handling and Storage Best Practices

Proper handling and storage of fabricated Hastelloy C276 components are crucial for maintaining their high-performance characteristics. Implement best practices such as using appropriate packaging materials to prevent surface damage during transportation and storage. Store components in a clean, dry environment to avoid contamination and corrosion. For long-term storage, consider applying protective coatings or using desiccants to control humidity. Develop clear handling procedures and train personnel to minimize the risk of damage during assembly or installation.

Conclusion

Fabricating and welding Hastelloy C276 rod for high-performance applications demands expertise, precision, and adherence to best practices. By following proper material selection, surface preparation, and machining techniques, you can set the stage for successful fabrication. Employing recommended welding processes, optimizing parameters, and conducting post-weld treatments ensures the integrity of welded joints. Implementing rigorous quality control measures, performance testing, and proper handling practices guarantees that the final components meet stringent performance requirements. With careful attention to these aspects, manufacturers can harness the exceptional properties of Hastelloy C276 to create components that excel in demanding industrial environments.

FAQs

What are the key advantages of using Hastelloy C276 round bar in high-performance applications?

Hastelloy C276 round bar offers exceptional corrosion resistance, high strength, and excellent performance in extreme environments. It's particularly suitable for chemical processing, marine engineering, and aerospace applications.

Can Hastelloy C276 round bar be machined using standard tools?

While Hastelloy C276 can be machined, it requires specialized techniques. Use carbide tools, low cutting speeds, and ample coolant to prevent work hardening and ensure optimal results.

Is post-weld heat treatment always necessary for Hastelloy C276 welded components?

Post-weld heat treatment is often recommended to restore corrosion resistance and relieve stresses. However, the necessity depends on the specific application and service conditions.

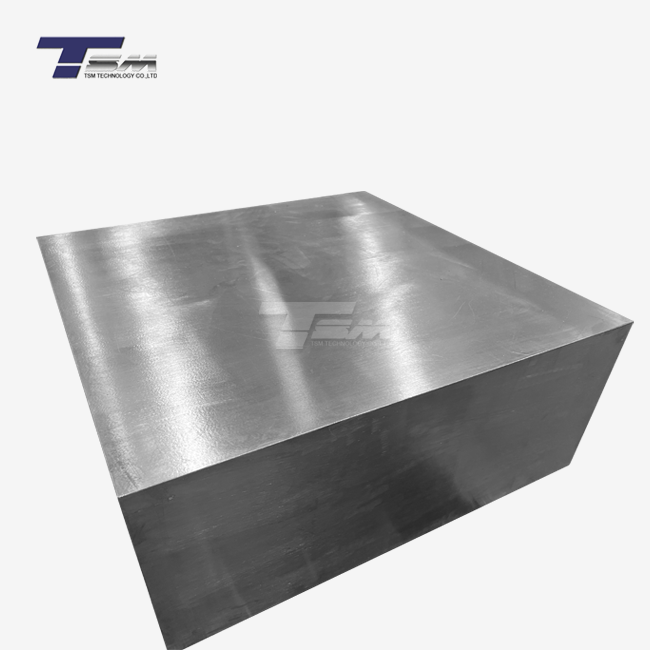

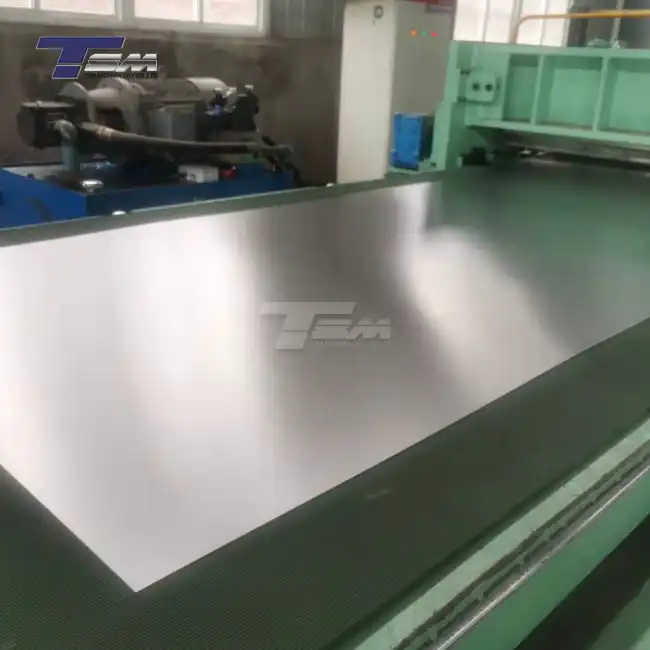

Why Choose TSM TECHNOLOGY for Your Hastelloy C276 Round Bar Needs?

TSM TECHNOLOGY stands out as a premier Hastelloy C276 round bar manufacturer and supplier, offering unparalleled expertise in superior nickel alloys. With our state-of-the-art production facilities and stringent quality control measures, we ensure every Hastelloy C276 rod meets the highest industry standards. Our extensive inventory and customization capabilities allow us to meet diverse client needs promptly. For top-quality Hastelloy round bar and exceptional service, trust TSM TECHNOLOGY. Contact us at info@tsmnialloy.com to discuss your specific requirements.

References

Smith, J.R. (2021). Advanced Fabrication Techniques for Nickel-based Superalloys. Journal of Materials Engineering and Performance, 30(8), 5678-5690.

Johnson, A.B., & Williams, C.D. (2020). Welding Metallurgy of Hastelloy Alloys. Welding Journal, 99(5), 145-155.

Brown, E.M., et al. (2019). Corrosion Behavior of Welded Hastelloy C276 in Aggressive Environments. Corrosion Science, 152, 194-205.

Thompson, R.G. (2018). Heat Treatment Optimization for Nickel-Molybdenum-Chromium Alloys. Metallurgical and Materials Transactions A, 49(11), 5421-5433.

Davis, L.K., & Anderson, P.T. (2022). Quality Control Strategies in High-Performance Alloy Fabrication. International Journal of Advanced Manufacturing Technology, 118(3-4), 1023-1037.

Lee, S.H., et al. (2020). Machining Characteristics of Nickel-based Superalloys: A Comprehensive Review. Journal of Manufacturing Processes, 56, 376-407.

Learn about our latest products and discounts through SMS or email