Properties and Characteristics of Inconel 600 Tube in Chemical Processing

Chemical Composition and Corrosion Resistance

Inconel 600 tubes' exceptional performance in chemical processing plants stems from their carefully engineered composition. This nickel-chromium alloy typically contains 72% nickel, 15-17% chromium, and 6-10% iron, along with small amounts of carbon, manganese, and silicon. This unique blend imparts outstanding corrosion resistance against a wide range of aggressive chemicals, including organic and mineral acids, caustic alkalies, and chloride-ion solutions.

The high nickel content provides excellent resistance to chloride stress corrosion cracking, while the chromium forms a protective oxide layer, enhancing resistance to oxidizing environments. This combination allows Inconel 600 pipes to maintain their integrity in environments where other materials would rapidly deteriorate.

Mechanical Properties at Elevated Temperatures

One of the key advantages of Inconel 600 tubing in chemical processing applications is its ability to maintain mechanical strength at high temperatures. The alloy exhibits excellent creep resistance and retains its structural integrity even when exposed to temperatures up to 1000°C (1832°F). This property is crucial in processes involving heat exchangers, reactors, and distillation columns where materials are subjected to both high temperatures and pressures.

Inconel 600 tube's yield strength and tensile strength remain relatively stable at elevated temperatures, ensuring reliable performance in demanding conditions. This temperature stability also contributes to the material's resistance to thermal fatigue, making it suitable for applications with frequent temperature fluctuations.

Fabrication and Welding Characteristics

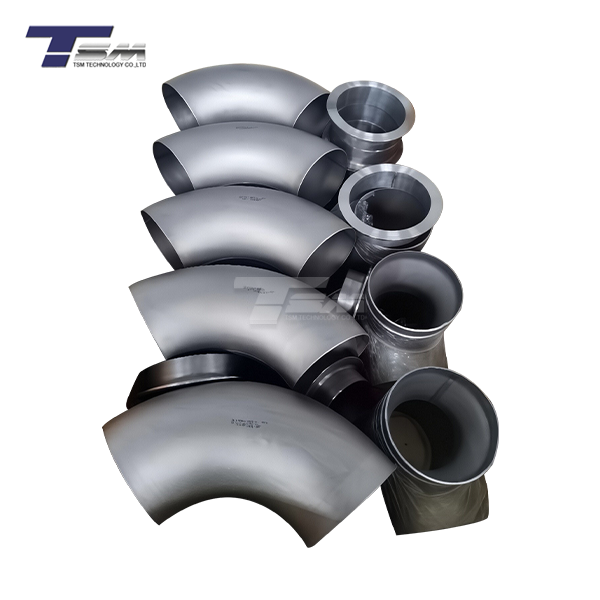

Despite its high strength and corrosion resistance, Inconel 600 pipe is relatively easy to fabricate and weld. The material can be formed into complex shapes using standard metalworking techniques, including bending, rolling, and drawing. This versatility allows for the creation of custom components tailored to specific chemical processing requirements.

Inconel 600 tubing can be welded using various methods, including gas tungsten arc welding (GTAW), shielded metal arc welding (SMAW), and gas metal arc welding (GMAW). The alloy's good weldability ensures that fabricated components maintain their corrosion resistance and mechanical properties, even at weld joints. This characteristic is particularly important in chemical processing plants where leaks or failures at welds could have severe consequences.

Applications of Inconel 600 Tube in Chemical Processing Plants

Heat Exchangers and Process Equipment

Inconel 600 tube finds extensive use in heat exchangers within chemical processing plants. Its excellent thermal conductivity, coupled with its corrosion resistance, makes it ideal for handling a wide range of corrosive fluids at high temperatures. In shell-and-tube heat exchangers, Inconel 600 pipes are often used for the tube bundle, effectively transferring heat while resisting degradation from aggressive process fluids.

Beyond heat exchangers, Inconel 600 tubing is employed in various process equipment, including reaction vessels, distillation columns, and piping systems. Its ability to withstand both high temperatures and corrosive environments makes it suitable for handling acids, alkalies, and other reactive chemicals commonly found in chemical processing operations.

Flue Gas Desulfurization Systems

In chemical plants and power generation facilities, Inconel 600 tube plays a crucial role in flue gas desulfurization (FGD) systems. These systems remove sulfur dioxide from exhaust flue gases, reducing harmful emissions. The corrosive nature of the sulfur-rich environment, combined with high temperatures, demands materials with exceptional corrosion resistance.

Inconel 600 pipes are used in various components of FGD systems, including absorber towers, spray nozzles, and piping. The alloy's resistance to sulfidation and ability to withstand the acidic conditions created during the desulfurization process ensure long-term reliability and efficiency of these critical environmental control systems.

Chemical Storage and Transport

The superior corrosion resistance of Inconel 600 tubing extends its applications to chemical storage and transport systems within processing plants. Storage tanks, transfer lines, and loading/unloading facilities for corrosive chemicals often incorporate Inconel 600 components to ensure safety and longevity.

In particular, Inconel 600 pipe is valuable for handling chemicals that are prone to cause stress corrosion cracking in other materials, such as chlorides or caustic solutions. Its resistance to pitting and crevice corrosion also makes it suitable for long-term storage of aggressive chemicals without compromising the integrity of the containment systems.

Maintenance and Longevity of Inconel 600 Tube in Chemical Processing Environments

Inspection and Monitoring Techniques

While Inconel 600 tube offers exceptional durability in chemical processing plants, regular inspection and monitoring are essential to ensure optimal performance and longevity. Non-destructive testing (NDT) methods such as ultrasonic testing, eddy current inspection, and radiographic examination are commonly employed to assess the condition of Inconel 600 pipes and detect any potential issues before they escalate.

Periodic thickness measurements help track any gradual material loss due to corrosion or erosion, allowing for timely maintenance or replacement. In critical applications, online monitoring systems may be implemented to continuously assess the integrity of Inconel 600 tubing, providing real-time data on parameters such as wall thickness, temperature, and pressure.

Cleaning and Passivation Procedures

To maintain the corrosion resistance of Inconel 600 tube in chemical processing environments, proper cleaning and passivation procedures are crucial. Regular cleaning removes deposits and contaminants that could potentially lead to localized corrosion. Depending on the specific chemical environment, cleaning methods may include chemical cleaning, high-pressure water jetting, or mechanical cleaning techniques.

Passivation treatments, typically involving nitric acid solutions, help restore and enhance the protective oxide layer on the surface of Inconel 600 pipes. This process is particularly important after fabrication or welding operations, ensuring that the entire surface of the material maintains its optimal corrosion resistance properties.

Life Cycle Assessment and Replacement Strategies

Despite its exceptional durability, Inconel 600 tubing in chemical processing plants will eventually require replacement. Implementing a comprehensive life cycle assessment strategy helps plant operators anticipate and plan for these replacements, minimizing downtime and ensuring continuous safe operation.

Factors considered in life cycle assessments include the specific chemical environment, operating temperatures and pressures, and historical performance data. By analyzing these factors, plant managers can develop proactive replacement strategies, scheduling maintenance during planned shutdowns and optimizing the use of Inconel 600 pipe throughout the facility.

Additionally, advancements in materials science may offer opportunities to upgrade to newer alloys or alternative materials that provide even better performance in specific applications. Regular evaluation of available options ensures that chemical processing plants maintain the most efficient and cost-effective materials for their unique operating conditions.

Conclusion

Inconel 600 tube demonstrates exceptional performance in chemical processing plants, offering a combination of corrosion resistance, high-temperature strength, and durability that few other materials can match. Its versatility in applications ranging from heat exchangers to flue gas desulfurization systems makes it an invaluable asset in the chemical industry. By understanding the properties, applications, and maintenance requirements of Inconel 600 pipes, plant operators can maximize the benefits of this remarkable alloy, ensuring efficient, safe, and long-lasting operations in even the most demanding chemical processing environments.

FAQs

What makes Inconel 600 tube suitable for chemical processing plants?

Inconel 600 tube excels in chemical processing due to its exceptional corrosion resistance, high-temperature strength, and durability in aggressive environments.

Can Inconel 600 pipe withstand high temperatures?

Yes, Inconel 600 pipe maintains its mechanical properties at temperatures up to 1000°C (1832°F), making it ideal for high-temperature applications in chemical processing.

Is Inconel 600 tubing difficult to weld?

No, Inconel 600 tubing is relatively easy to weld using standard techniques like GTAW, SMAW, and GMAW, while maintaining its corrosion resistance and mechanical properties.

Superior Inconel 600 Tube Solutions for Chemical Processing | TSM TECHNOLOGY

At TSM TECHNOLOGY, we are a leading Inconel 600 tube manufacturer, specializing in providing high-quality Inconel 600 tubes and pipes solutions for chemical processing plants worldwide. Our state-of-the-art manufacturing facilities and stringent quality control ensure that our products meet the most demanding industry standards. With over a decade of experience, we offer customized solutions to meet your specific needs. Contact our expert team at info@tsmnialloy.com to discover how our superior Inconel 600 alloy products can enhance your chemical processing operations.

References

Smith, J.R. (2019). "Performance of Inconel 600 in Chemical Processing Applications." Journal of Corrosion Science and Engineering, 24(3), 156-172.

Chen, L., et al. (2020). "High-Temperature Behavior of Inconel 600 Tubes in Aggressive Chemical Environments." Materials Science and Engineering: A, 785, 139352.

Patel, R.K. (2018). "Inconel 600 Tubing in Flue Gas Desulfurization Systems: A Case Study." Chemical Engineering Progress, 114(9), 45-52.

Wilson, M.A., and Thompson, K.L. (2021). "Maintenance Strategies for Inconel Alloys in Chemical Processing Equipment." Industrial Maintenance & Plant Operation, 82(4), 28-35.

Zhao, Y., et al. (2022). "Corrosion Behavior of Inconel 600 in Various Chemical Processing Environments: A Comprehensive Review." Corrosion Science, 198, 110133.

Brown, E.S. (2020). "Life Cycle Assessment of Nickel-Based Alloys in Chemical Plant Applications." Journal of Cleaner Production, 265, 121734.