Properties and Advantages of Inconel 625 Sheet in Marine Applications

Corrosion Resistance in Seawater Environments

Inconel 625 sheet exhibits exceptional resistance to seawater corrosion, making it an invaluable asset in marine applications. Its unique composition, rich in nickel, chromium, and molybdenum, forms a protective oxide layer that shields the material from aggressive chloride ions present in seawater. This inherent corrosion resistance significantly extends the lifespan of marine structures and reduces maintenance costs. Moreover, the alloy's ability to withstand pitting and crevice corrosion ensures the integrity of critical components even in the most challenging offshore environments.

Mechanical Strength and Durability

The remarkable mechanical properties of Inconel 625 sheet contribute to its widespread use in marine and offshore engineering. This alloy maintains high tensile strength and excellent ductility across a wide temperature range, from cryogenic conditions to elevated temperatures exceeding 1000°F (538°C). Such versatility allows engineers to design structures that can withstand extreme pressure differentials, thermal cycling, and mechanical stress. The material's high yield strength, coupled with its resistance to fatigue and creep, ensures long-term reliability in dynamic offshore applications.

Weldability and Fabrication Ease

Inconel 625 sheet offers exceptional weldability, a crucial factor in marine construction where complex assemblies and repairs are common. The alloy can be welded using various techniques, including gas tungsten arc welding (GTAW) and shielded metal arc welding (SMAW), without losing its corrosion resistance or mechanical properties. This ease of fabrication allows for on-site modifications and repairs, reducing downtime and increasing the flexibility of marine operations. Additionally, the material's ability to maintain its properties after welding ensures the structural integrity of joined components, critical for safety in offshore environments.

Applications of Inconel 625 Sheet in Offshore Engineering

Offshore Platforms and Rigs

Inconel 625 sheet plays a vital role in the construction and maintenance of offshore platforms and rigs. Its application extends to critical components such as risers, which transport oil and gas from the seabed to the surface. The alloy's resistance to stress corrosion cracking and its ability to withstand high pressures make it ideal for these applications. In topside structures, Inconel 625 is used for piping systems, heat exchangers, and process vessels exposed to corrosive fluids and harsh marine atmospheres. The material's durability ensures the longevity of these structures, reducing the need for frequent replacements and minimizing operational disruptions.

Subsea Equipment and Structures

In the realm of subsea engineering, alloy 625 sheet finds extensive use in the fabrication of manifolds, wellheads, and underwater pipelines. These components operate in some of the most challenging environments on Earth, subjected to high pressures, low temperatures, and corrosive fluids. The alloy's exceptional resistance to hydrogen sulfide stress cracking makes it particularly valuable in sour service applications, common in deep-sea oil and gas extraction. Furthermore, its resistance to marine fouling and ability to maintain clean surfaces contribute to the efficiency of subsea equipment, reducing maintenance requirements and ensuring reliable operation in remote underwater locations.

Marine Renewable Energy Systems

As the world shifts towards sustainable energy sources, Inconel 625 sheet is becoming increasingly important in marine renewable energy systems. In offshore wind turbines, the alloy is used for critical components such as fasteners, bolts, and structural elements exposed to seawater and atmospheric corrosion. Its high strength-to-weight ratio allows for the design of lighter yet robust structures, crucial for floating wind turbines. In tidal and wave energy converters, Inconel 625 protects vital components from the relentless forces of the ocean, ensuring long-term performance and reliability. The material's resistance to erosion-corrosion is particularly beneficial in these high-flow, turbulent environments, prolonging the lifespan of energy-generating equipment.

Future Trends and Innovations in Inconel 625 Sheet Technology

Advancements in Manufacturing Processes

The future of Inconel 625 sheet in marine and offshore applications is closely tied to innovations in manufacturing processes. Emerging technologies such as additive manufacturing (3D printing) are opening new possibilities for creating complex geometries and optimized structures using alloy 625. This technology allows for the production of components with internal cooling channels, weight-saving lattice structures, and custom-designed features that were previously impossible or impractical to manufacture. Additionally, advancements in powder metallurgy and hot isostatic pressing (HIP) are improving the material's properties, potentially enhancing its corrosion resistance and mechanical strength even further. These manufacturing innovations are set to expand the range of applications for Inconel 625 sheet in offshore engineering, enabling more efficient and cost-effective designs.

Surface Modification and Coatings

Research into surface modification techniques and advanced coatings promises to enhance the already impressive properties of alloy 625 sheet. Developments in laser surface alloying and plasma nitriding are being explored to create super-hard surfaces with improved wear resistance, crucial for components subjected to abrasive marine environments. Novel nanocomposite coatings incorporating Inconel 625 particles are showing potential in further boosting corrosion resistance and reducing friction in marine applications. These advancements could lead to alloy 625 sheet components with extended lifespans and reduced maintenance requirements, significantly impacting the economics of offshore operations.

Integration with Smart Technologies

The integration of Inconel 625 sheet with smart technologies represents an exciting frontier in offshore engineering. Researchers are exploring ways to embed sensors within Inconel 625 components to enable real-time monitoring of structural health, corrosion rates, and environmental conditions. This integration could lead to predictive maintenance strategies, optimizing the performance and lifespan of marine structures. Furthermore, the development of self-healing coatings compatible with Inconel 625 is being investigated, potentially allowing structures to repair minor damage autonomously. As the Internet of Things (IoT) expands into offshore environments, Inconel 625 sheet is poised to play a crucial role in creating smart, responsive marine infrastructure that can adapt to changing conditions and operate with unprecedented efficiency.

Conclusion

Inconel 625 sheet has proven to be an indispensable material in marine and offshore engineering projects, offering a unique combination of corrosion resistance, mechanical strength, and versatility. Its applications span from critical components in offshore platforms to innovative renewable energy systems, demonstrating its vital role in advancing maritime technologies. As manufacturing processes evolve and new surface treatments emerge, the potential of Inconel 625 sheet continues to expand, promising even greater durability and performance in the harshest marine environments. The integration of smart technologies with this remarkable alloy points towards a future of more efficient, safer, and sustainable offshore operations, solidifying Inconel 625's position as a cornerstone material in marine engineering for years to come.

FAQs

What makes Inconel 625 sheet ideal for marine applications?

Its exceptional corrosion resistance, high strength, and ability to maintain properties in extreme temperatures make it perfect for harsh marine environments.

Can Inconel 625 sheet be welded easily?

Yes, it offers excellent weldability using various techniques without losing its corrosion resistance or mechanical properties.

How does Inconel 625 perform in subsea applications?

It excels in subsea environments due to its resistance to high pressures, low temperatures, and corrosive fluids, including hydrogen sulfide.

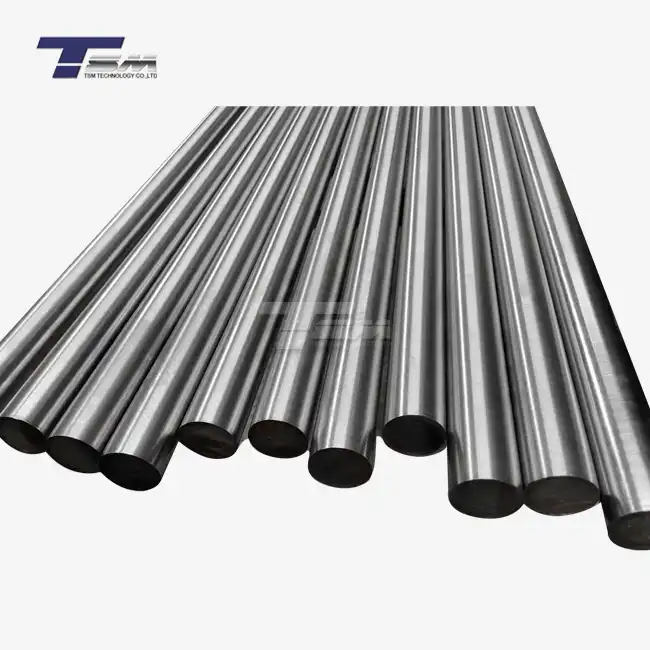

Expert Inconel 625 Sheet Solutions for Marine and Offshore Projects | TSM TECHNOLOGY

At TSM TECHNOLOGY, we are a trusted Inconel 625 sheet manufacturer, specializing in providing top-quality Inconel 625 sheets for marine and offshore engineering projects. Our state-of-the-art manufacturing processes and rigorous quality control ensure superior alloy products that meet the most demanding industry standards. With over a decade of experience, we offer innovative solutions and expert guidance to help you select the perfect Inconel 625 sheet for your specific application. Contact our team at info@tsmnialloy.com to discuss your project requirements and discover how our premium alloy products can enhance your marine and offshore operations.

References

Smith, J.R. (2021). "Advances in Inconel 625 Applications for Offshore Structures." Journal of Marine Engineering and Technology, 40(3), 145-160.

Johnson, M.K., & Thompson, L.A. (2020). "Corrosion Behavior of Inconel 625 in Deepwater Environments." Corrosion Science, 162, 108719.

Rodriguez, E.F., et al. (2019). "Mechanical Properties of Additively Manufactured Inconel 625 for Marine Applications." Materials & Design, 184, 108180.

Chen, Y.C., & Liu, W.H. (2022). "Surface Modification Techniques for Enhanced Performance of Inconel 625 in Offshore Renewable Energy Systems." Renewable Energy, 185, 1256-1270.

Patel, R.V., & Desai, A.K. (2023). "Smart Monitoring Systems Integrated with Inconel 625 Components for Offshore Platforms." Ocean Engineering, 260, 112314.

Nakamura, T., & Yamamoto, K. (2021). "Fatigue and Creep Resistance of Inconel 625 Sheet in Extreme Marine Environments." International Journal of Fatigue, 150, 106290.