- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Is Hastelloy C276 Tube Pressure Tested?

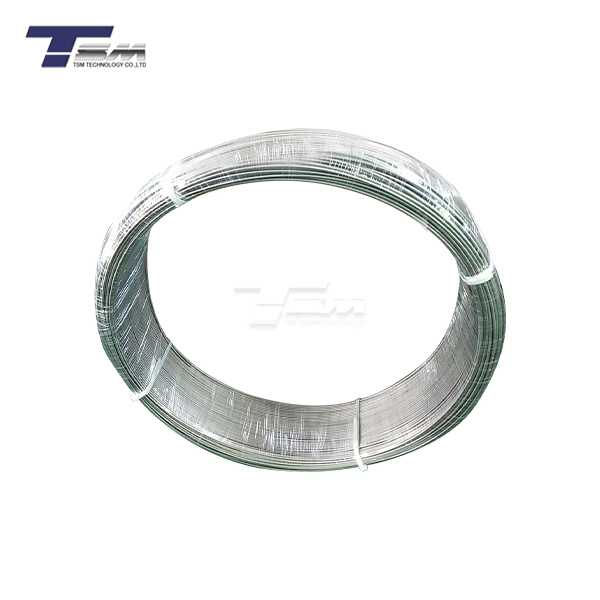

Hastelloy C276 tube pressure testing is a critical process that ensures the reliability and safety of this high-performance nickel-chromium-molybdenum alloy in demanding industrial applications. The pressure testing procedure for Hastelloy C276 tubing typically involves hydrostatic testing, where the tube is filled with water or another incompressible fluid and subjected to high pressure. This pressure, often exceeding the tube's maximum operating pressure by a significant margin, is maintained for a specified period to detect any leaks, deformations, or weaknesses in the material. The test also verifies the tube's ability to withstand pressure without bursting or permanent deformation, ensuring its suitability for use in corrosive and high-stress environments.

Understanding Hastelloy C276 Tube Properties

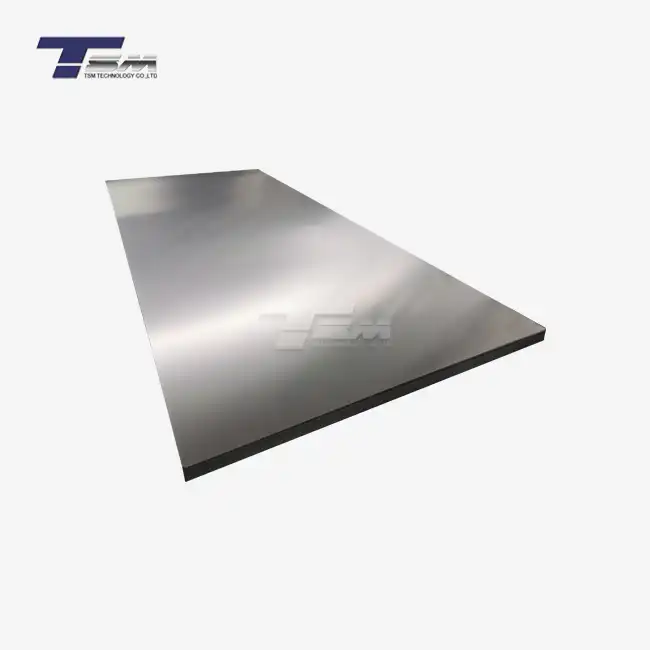

Composition and Characteristics

Hastelloy C276 is a remarkable nickel-chromium-molybdenum-tungsten alloy known for its exceptional corrosion resistance and strength. This superalloy contains approximately 57% nickel, 16% chromium, 16% molybdenum, and smaller amounts of tungsten, iron, and other elements. The unique composition of Hastelloy C276 gives it superior resistance to a wide range of corrosive environments, including oxidizing and reducing conditions.

The alloy's excellent mechanical properties make it an ideal choice for manufacturing Hastelloy C276 seamless pipes and tubes. These components exhibit high strength and toughness across a wide temperature range, from cryogenic conditions to elevated temperatures exceeding 1000°F (538°C). The material's low carbon content also contributes to its outstanding welding characteristics and resistance to intergranular corrosion.

Applications of Hastelloy C276 Tubing

Hastelloy C276 tubing finds extensive use in various industries due to its exceptional performance in harsh environments. Some key applications include:

- Chemical processing equipment

- Flue gas desulfurization systems

- Offshore oil and gas production

- Nuclear waste treatment facilities

- Pharmaceutical manufacturing

- Pulp and paper production

In these applications, Hastelloy C276 tubes are often subjected to extreme conditions, including high pressures, elevated temperatures, and corrosive media. Therefore, rigorous pressure testing is essential to ensure the integrity and reliability of the tubing in service.

Manufacturing Process of Hastelloy C276 Seamless Pipe

The production of Hastelloy C276 seamless pipe involves several carefully controlled steps to achieve the desired properties and quality. The process typically begins with the melting of raw materials in an electric arc furnace or vacuum induction melting furnace to create the alloy ingot. This ingot is then subjected to hot working processes such as extrusion or piercing to form the initial tubular shape.

Following the initial forming, the tube undergoes multiple cold working and heat treatment cycles to refine its grain structure and achieve the required dimensions and mechanical properties. The final stages of production include precision machining, surface finishing, and rigorous quality control inspections, including non-destructive testing and pressure testing.

Pressure Testing Procedures for Hastelloy C276 Tubes

Hydrostatic Testing Methodology

Hydrostatic testing is the most common method used for pressure testing Hastelloy C276 tubes. This non-destructive test involves filling the tube with water or another incompressible fluid and gradually increasing the internal pressure to a predetermined test pressure. The test pressure is typically 1.5 to 2 times the maximum allowable working pressure (MAWP) of the tube, depending on the specific industry standards and customer requirements.

During the test, the pressure is maintained for a specified period, usually ranging from 10 to 30 minutes, while inspectors carefully monitor the tube for any signs of leakage, deformation, or failure. Advanced testing equipment, including high-precision pressure gauges and leak detection systems, is used to ensure accurate results and identify even minute imperfections.

Pneumatic Testing Alternatives

While hydrostatic testing is the preferred method for pressure testing Hastelloy C276 tubing, pneumatic testing using compressed air or inert gases may be employed in certain situations. Pneumatic testing is generally used when water contamination must be avoided or when the weight of water could pose structural concerns.

However, pneumatic testing carries higher risks due to the compressibility of gases and the potential for rapid energy release in case of failure. As a result, it is typically conducted at lower test pressures compared to hydrostatic testing and requires additional safety precautions, including remote monitoring and protective barriers.

Specialized Testing for Extreme Conditions

In some applications where Hastelloy C276 tubes are subjected to extreme temperatures or corrosive environments, specialized pressure testing procedures may be employed. These can include:

- High-temperature pressure testing: Conducted at elevated temperatures to simulate actual operating conditions

- Corrosion testing: Combining pressure testing with exposure to corrosive media to evaluate long-term performance

- Cyclic pressure testing: Subjecting the tube to repeated pressure cycles to assess fatigue resistance

- Burst testing: Destructive testing to determine the ultimate pressure capacity of the tube

These specialized tests provide valuable data on the performance limits of Hastelloy C276 tubing and help ensure its suitability for specific applications.

Quality Control and Certification of Hastelloy C276 Tube Pressure Tests

Industry Standards and Specifications

Pressure testing of Hastelloy C276 tubes is governed by various industry standards and specifications to ensure consistency and reliability. Some of the key standards include:

- ASTM E1003: Standard Test Method for Hydrostatic Leak Testing

- ASME B31.3: Process Piping

- API 570: Piping Inspection Code: In-service Inspection, Rating, Repair, and Alteration of Piping Systems

- NACE MR0175/ISO 15156: Materials for use in H2S-containing environments in oil and gas production

These standards provide guidelines for test procedures, acceptance criteria, and documentation requirements. Adherence to these standards ensures that Hastelloy C276 tubing meets the rigorous quality and safety requirements of various industries.

Documentation and Traceability

Proper documentation is crucial in the pressure testing process for Hastelloy C276 tubes. Each test is meticulously recorded, with detailed information including:

- Test date and location

- Tube identification numbers and material certifications

- Test pressure and duration

- Test medium used

- Ambient conditions

- Test results and observations

- Inspector's signature and certification

This comprehensive documentation ensures full traceability of each Hastelloy C276 tube throughout its lifecycle, from manufacturing to installation and service. It also provides valuable data for quality control, regulatory compliance, and continuous improvement of manufacturing processes.

Third-Party Verification and Certification

To ensure the highest level of quality and reliability, many industries require third-party verification and certification of pressure tests for Hastelloy C276 tubing. Independent inspection agencies or certified testing laboratories may be engaged to witness or conduct the pressure tests, providing an unbiased assessment of the tube's performance.

These third-party inspectors verify compliance with relevant standards, review test procedures and equipment calibration, and validate test results. Their involvement adds an extra layer of assurance for end-users, particularly in critical applications where failure could have severe consequences.

Conclusion

Pressure testing of Hastelloy C276 tubes is a critical process that ensures the integrity and reliability of these high-performance components in demanding industrial applications. Through rigorous hydrostatic testing, supplemented by specialized procedures when necessary, manufacturers can verify the tube's ability to withstand extreme pressures and corrosive environments. Adherence to industry standards, meticulous documentation, and third-party verification further enhance the quality assurance process, providing confidence in the performance and safety of Hastelloy C276 tubing across various sectors.

Contact Us

For more information about our premium Hastelloy C276 tubes and our comprehensive testing procedures, please contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of experts is ready to assist you in selecting the right Hastelloy C276 products for your specific application needs.

References

ASTM International. (2020). ASTM E1003-20: Standard Test Method for Hydrostatic Leak Testing.

American Society of Mechanical Engineers. (2018). ASME B31.3-2018: Process Piping.

American Petroleum Institute. (2016). API 570: Piping Inspection Code: In-service Inspection, Rating, Repair, and Alteration of Piping Systems.

NACE International. (2015). NACE MR0175/ISO 15156: Materials for use in H2S-containing environments in oil and gas production.

Haynes International. (2021). Hastelloy C-276 alloy: Technical Data Sheet.

Special Metals Corporation. (2019). Inconel alloy C-276: Product Handbook.

Learn about our latest products and discounts through SMS or email