Essential Quality Tests for Hastelloy C276 Tubing

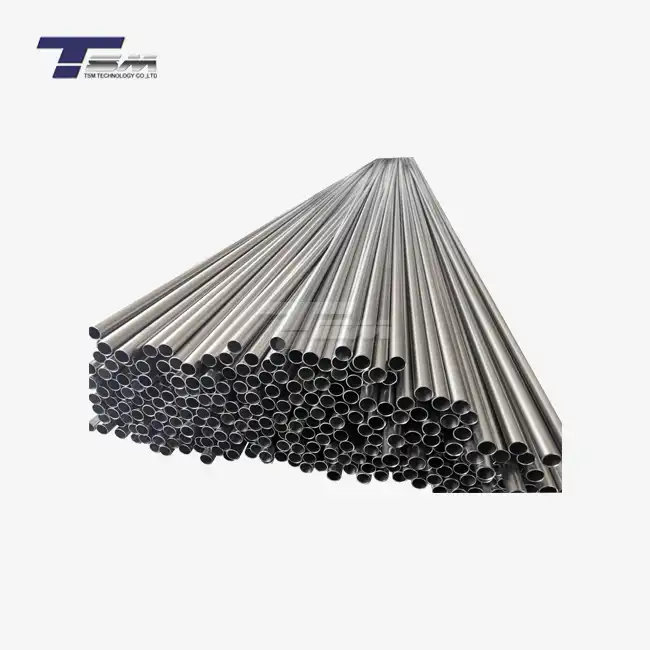

Visual Inspection and Surface Quality Assessment

The first step in ensuring the quality of Hastelloy C276 tubing begins with a thorough visual inspection. This process involves examining the entire surface of the tube for any visible defects, such as scratches, dents, or irregularities. Inspectors use high-powered magnification tools to scrutinize the surface, looking for any signs of manufacturing flaws or handling damage.

Surface quality is paramount for Hastelloy C276 seamless pipes, as even minor imperfections can lead to corrosion initiation points or stress concentration areas. The surface finish is evaluated using profilometers to measure roughness and ensure it meets the specified requirements. A smooth surface not only enhances the alloy's corrosion resistance but also improves fluid flow characteristics in piping applications.

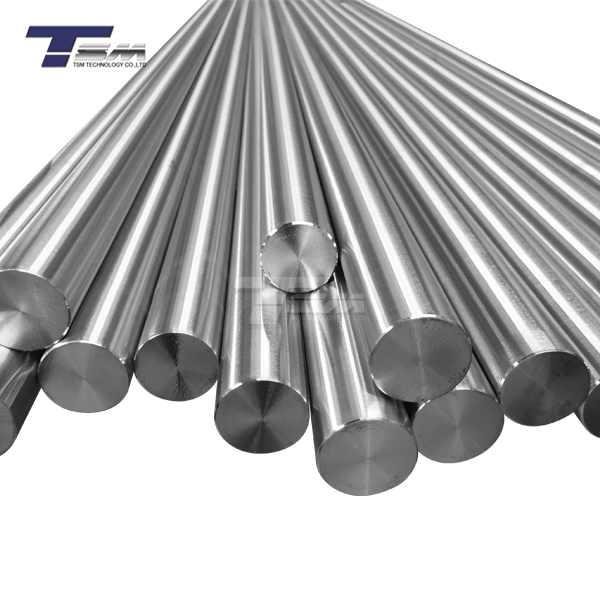

Dimensional Verification and Tolerance Checks

Precise dimensional control is critical for Hastelloy C276 tubes to ensure proper fit and function in various engineering applications. Inspectors use advanced measuring instruments such as micrometers, calipers, and laser-based systems to verify the tube's outer diameter, inner diameter, wall thickness, and length.

Tolerance checks are performed to confirm that the dimensions fall within the acceptable range specified by industry standards or customer requirements. For Hastelloy C276 seamless pipe, maintaining tight tolerances is especially important to ensure uniform material properties and consistent performance across the entire length of the tube.

Chemical Composition Analysis

The unique properties of Hastelloy C276 stem from its carefully balanced chemical composition. To verify that the alloy meets the required specifications, samples undergo rigorous chemical analysis. Techniques such as optical emission spectroscopy (OES) or X-ray fluorescence (XRF) are employed to determine the precise percentages of elements present in the alloy.

Key elements in Hastelloy C276 tubing, including nickel, chromium, molybdenum, and tungsten, are quantified to ensure they fall within the specified ranges. This analysis is crucial for confirming the material's identity and predicting its performance in corrosive environments.

Advanced Testing Methods for Hastelloy C276 Seamless Pipe

Mechanical Property Evaluation

The mechanical integrity of Hastelloy C276 seamless pipe is verified through a series of standardized tests. Tensile testing is conducted to determine the alloy's yield strength, ultimate tensile strength, and elongation. These properties are essential for understanding how the material will behave under various load conditions in service.

Hardness testing, typically using the Rockwell or Brinell scales, provides insight into the material's resistance to deformation and wear. For applications involving cyclic loading, fatigue testing may be performed to assess the long-term durability of Hastelloy C276 tubing.

Non-Destructive Testing (NDT) Techniques

Non-destructive testing methods play a crucial role in identifying internal defects or discontinuities in Hastelloy C276 tubes without compromising their integrity. Ultrasonic testing (UT) is widely used to detect subsurface flaws, such as inclusions or cracks, by analyzing the reflection of high-frequency sound waves.

Eddy current testing is another valuable NDT technique for Hastelloy C276 seamless pipes. This method can detect surface and near-surface defects by inducing electromagnetic fields in the material and analyzing the resulting eddy currents. It's particularly effective for identifying small cracks or variations in wall thickness.

Corrosion Resistance Verification

Given that Hastelloy C276 is often chosen for its exceptional corrosion resistance, verifying this property is paramount. Corrosion testing typically involves exposing samples of the Hastelloy C276 tubing to simulated service environments or standardized corrosive media.

Electrochemical testing, such as potentiodynamic polarization, can provide quantitative data on the alloy's corrosion behavior. For specific applications, immersion tests or stress corrosion cracking assessments may be conducted to evaluate long-term performance under realistic conditions.

Specialized Inspections for High-Performance Hastelloy C276 Tubing

Microstructural Analysis

Examining the microstructure of Hastelloy C276 tubes provides valuable insights into the material's properties and processing history. Metallographic analysis involves preparing polished and etched samples for observation under optical or electron microscopes. This inspection reveals grain size, phase distribution, and any potential microstructural anomalies that could affect performance.

For Hastelloy C276 seamless pipe, a uniform, fine-grained structure is typically desired for optimal mechanical properties and corrosion resistance. Microstructural analysis can also help identify any undesirable precipitates or segregation that might compromise the alloy's integrity.

Weld Integrity Evaluation

While Hastelloy C276 tubing is often supplied in seamless form, welded joints may be present in certain applications or fabricated assemblies. Assessing the quality of these welds is critical to ensure the overall integrity of the system. Radiographic testing (RT) is commonly employed to detect internal weld defects such as porosity, lack of fusion, or inclusions.

For Hastelloy C276 pipes with welded seams, additional tests like bend testing or guided bend tests may be performed to evaluate the ductility and soundness of the weld. Macro-etching techniques can also reveal the heat-affected zone and any potential weaknesses in the weld structure.

High-Temperature Performance Testing

Many applications for Hastelloy C276 tubing involve elevated temperatures, making it essential to verify the alloy's performance under such conditions. Creep testing is conducted to assess the material's resistance to time-dependent deformation under constant load and high temperature.

Thermal cycling tests may also be performed on Hastelloy C276 seamless pipes to evaluate their resistance to thermal fatigue and ensure dimensional stability across a range of operating temperatures. These specialized tests help predict the long-term reliability of the alloy in demanding thermal environments.

Conclusion

The comprehensive quality testing regime for Hastelloy C276 tubes encompasses a wide array of inspections and evaluations, each designed to verify specific aspects of the material's performance and integrity. From basic visual and dimensional checks to advanced non-destructive testing and specialized high-temperature assessments, these quality control measures ensure that Hastelloy C276 seamless pipes and tubing meet the exacting standards required for critical applications. By rigorously adhering to these testing protocols, manufacturers and end-users can confidently rely on the exceptional properties of Hastelloy C276 in the most demanding industrial environments.

Contact Us

For more information about our high-quality Hastelloy C276 tubing and seamless pipes, or to discuss your specific project requirements, please contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of experts is ready to assist you in selecting the right alloy solutions for your challenging applications.