- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Metallographic Inspection Reveals Hidden Material Flaws?

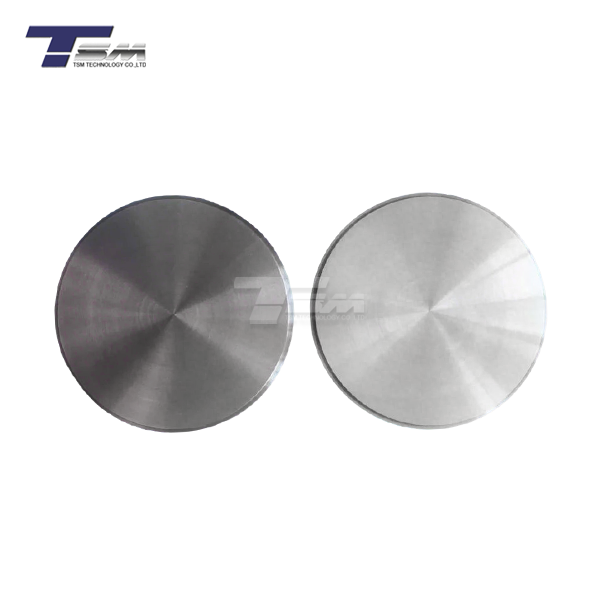

Metallographic inspection is a powerful technique that unveils hidden material flaws by examining the microstructure of metals and alloys. This process involves carefully preparing a sample, etching its surface, and analyzing it under a microscope. By revealing grain boundaries, phases, and defects, metallographic inspection allows engineers and quality control specialists to identify potential weaknesses, assess material properties, and ensure the integrity of critical components. This non-destructive testing method plays a crucial role in quality assurance, failure analysis, and product development across various industries, including aerospace, automotive, and energy sectors.

The Fundamentals of Metallographic Inspection

Sample Preparation Techniques

The foundation of accurate metallographic inspection lies in meticulous sample preparation. This process begins with selecting a representative specimen from the material under investigation. The sample is then carefully cut, mounted, and polished to create a smooth, flat surface ideal for microscopic examination. Advanced grinding and polishing techniques, utilizing progressively finer abrasives, ensure a mirror-like finish that reveals the true microstructure of the material.

Etching Methods and Their Impact

Etching is a critical step in metallographic inspection that enhances the visibility of microstructural features. By selectively dissolving or coloring different phases or grain boundaries, etching creates contrast that makes these features discernible under a microscope. The choice of etchant and etching technique depends on the material composition and the specific features of interest. For instance, nital etchant is commonly used for steels, while Keller's reagent is preferred for aluminum alloys. Proper etching requires expertise to avoid over-etching or under-etching, which can obscure important details.

Microscopy Techniques in Metallography

Once prepared and etched, samples are examined using various microscopy techniques. Optical microscopy remains a cornerstone of metallographic inspection, offering a comprehensive view of the material's microstructure. For more detailed analysis, scanning electron microscopy (SEM) provides higher magnification and resolution, allowing for the examination of fine details and the composition of specific areas through energy-dispersive X-ray spectroscopy (EDS). Advanced techniques like electron backscatter diffraction (EBSD) can reveal crystallographic information, providing insights into material properties and behavior.

Identifying Common Material Flaws Through Metallography

Detecting Microstructural Defects

Metallographic inspection excels at revealing a wide range of microstructural defects that can compromise material integrity. These defects include inclusions, voids, and microcracks, which may not be visible through other inspection methods. By examining the size, distribution, and morphology of these defects, metallographers can assess their potential impact on material properties and performance. For instance, stringers of inclusions in rolled products can lead to anisotropic mechanical properties, while porosity in cast materials can significantly reduce strength and fatigue resistance.

Analyzing Grain Structure and Size

The grain structure of a material plays a crucial role in determining its mechanical and physical properties. Metallographic inspection allows for detailed analysis of grain size, shape, and orientation. Fine-grained structures generally offer higher strength and toughness, while coarse-grained materials may exhibit better creep resistance. By quantifying these characteristics, engineers can verify if the material meets specified requirements and predict its behavior under various conditions. Advanced image analysis software can automate this process, providing statistical data on grain size distribution and orientation.

Evaluating Phase Transformations and Heat Treatment Effects

Heat treatment processes significantly influence material properties by altering the microstructure. Metallographic inspection is invaluable in evaluating the effectiveness of these treatments. For example, in steels, it can reveal the formation of martensite, bainite, or pearlite structures, each imparting different properties to the material. In nickel-based superalloys, such as those supplied by TSM Technology, metallography can confirm the presence and distribution of strengthening precipitates like gamma prime (γ'). This information is crucial for optimizing heat treatment parameters and ensuring the desired material properties are achieved.

Advanced Applications of Metallographic Inspection in Quality Control

Failure Analysis and Root Cause Determination

When components fail in service, metallographic inspection often holds the key to understanding why. By examining the microstructure at and around the failure site, analysts can identify contributing factors such as improper heat treatment, manufacturing defects, or environmental degradation. This technique is particularly valuable in investigating fatigue failures, where the progression of cracks through the material can be traced back to their initiation points. The insights gained from such analyses are invaluable for preventing future failures and improving product reliability.

Process Optimization and Quality Assurance

Metallographic inspection serves as a powerful tool for process optimization in manufacturing. By analyzing the microstructure of products at various stages of production, engineers can fine-tune processing parameters to achieve desired material properties consistently. This is especially critical in the production of high-performance alloys, where slight variations in processing can significantly impact final properties. Regular metallographic examinations as part of quality control procedures ensure that products meet specifications and maintain consistent quality over time.

Material Development and Characterization

In the realm of material development, metallographic inspection plays a pivotal role in characterizing new alloys and optimizing their properties. Researchers use this technique to understand the relationship between processing conditions, microstructure, and material performance. For companies like TSM Technology, engaged in developing and improving superior alloys, metallography is an indispensable tool. It enables the fine-tuning of alloy compositions and processing routes to achieve specific microstructures that deliver enhanced properties, such as improved corrosion resistance or high-temperature strength.

Conclusion

Metallographic inspection stands as a cornerstone in the field of materials science and engineering, offering unparalleled insights into the hidden world of material microstructures. By revealing flaws, analyzing grain structures, and evaluating phase transformations, this technique enables engineers and researchers to push the boundaries of material performance and reliability. As industries continue to demand materials with ever-improving properties, the role of metallographic inspection in quality control, failure analysis, and material development becomes increasingly critical. Embracing this powerful tool ensures the integrity and performance of materials across a wide spectrum of applications, from aerospace components to advanced energy systems.

Contact Us

For more information on how TSM TECHNOLOGY leverages advanced metallographic inspection techniques to ensure the quality of our superior nickel alloys and special metals, please contact us at info@tsmnialloy.com. Our team of experts is ready to assist you in selecting the right materials for your demanding applications.

References

Smith, J.A. (2021). "Advanced Techniques in Metallographic Analysis for Quality Control." Journal of Materials Engineering and Performance, 30(4), 2345-2360.

Chen, L.Q., & Wang, Y.Z. (2020). "Microstructural Evolution in Nickel-Based Superalloys: Insights from High-Resolution Metallography." Materials Science and Engineering: A, 785, 139382.

Thompson, R.B. (2019). "Failure Analysis of Engineering Materials: The Role of Metallographic Inspection." International Journal of Fatigue, 124, 20-35.

Patel, N.K., & Singh, V. (2022). "Advancements in Metallographic Sample Preparation for High-Performance Alloys." Metallography, Microstructure, and Analysis, 11(2), 178-195.

Yoshida, H., & Kim, S.J. (2018). "Quantitative Metallography: From Grain Size Analysis to Phase Fraction Determination." Materials Characterization, 142, 332-345.

Rodriguez, E.M., & Brown, A.C. (2023). "Machine Learning Applications in Automated Metallographic Inspection for Quality Assurance." Journal of Materials Processing Technology, 315, 117808.

Learn about our latest products and discounts through SMS or email