The Importance of Nickel Alloy Round Bars in Power Plant Components

Turbine Components: Enhancing Efficiency and Durability

Nickel alloy round bars are extensively used in the manufacturing of turbine components, playing a vital role in enhancing the efficiency and durability of power generation systems. These high-performance materials are employed in critical parts such as turbine blades, rotors, and shafts. The exceptionally high-temperature strength of nickel alloys allows turbines to operate at higher temperatures, resulting in improved thermal efficiency and increased power output.

For instance, in steam turbines, nickel alloy round bars are used to create blades that can withstand the extreme heat and pressure of superheated steam. The superior creep resistance of these alloys ensures that the turbine components maintain their shape and integrity over extended periods, even under challenging operating conditions. This translates to longer service life and reduced maintenance requirements, ultimately contributing to the overall reliability of power plants.

Moreover, the corrosion resistance of nickel alloys protects turbine components from the harmful effects of steam and other corrosive elements present in the power generation environment. This protection is crucial for maintaining the performance and longevity of turbine systems, especially in coastal areas where salt-laden air can accelerate corrosion.

Heat Exchanger Tubes: Optimizing Thermal Transfer

Heat exchangers are critical components in power plants, responsible for transferring heat between different fluids. Nickel alloy round bars are widely used in the fabrication of heat exchanger tubes due to their excellent thermal conductivity and corrosion resistance. These properties make them ideal for applications in both conventional and nuclear power plants.

In fossil fuel power plants, nickel alloy heat exchanger tubes are used in boilers and steam generators. The high-temperature strength of these alloys allows for efficient heat transfer from combustion gases to water, producing the steam necessary to drive turbines. The corrosion resistance of nickel alloys also protects the tubes from the aggressive nature of flue gases, ensuring long-term reliability and performance.

In nuclear power plants, nickel alloy round bars are used to manufacture heat exchanger tubes in steam generators. These tubes act as a barrier between the primary coolant loop (which contains radioactive material) and the secondary loop that drives the turbines. The exceptional corrosion resistance and mechanical properties of nickel alloys ensure the integrity of this critical boundary, maintaining safety and efficiency in nuclear power generation.

Piping Systems: Ensuring Reliability and Safety

Nickel alloy round bars are essential in the construction of piping systems throughout power plants. These systems are responsible for transporting various fluids, including high-pressure steam, coolants, and corrosive chemicals. The use of nickel alloys in piping ensures the safe and efficient operation of power generation facilities.

In high-temperature applications, such as steam lines in thermal power plants, nickel alloy pipes offer superior resistance to creep and thermal fatigue. This is crucial for maintaining the structural integrity of the piping system over long periods of operation at elevated temperatures. The high strength-to-weight ratio of nickel alloys also allows for the design of thinner-walled pipes, reducing overall system weight without compromising performance.

For nuclear power plants, nickel alloy piping is used in critical systems such as the primary coolant loop. The exceptional corrosion resistance of these alloys helps prevent stress corrosion cracking, a significant concern in nuclear applications. By using nickel alloy round bars in piping systems, power plant operators can ensure the long-term reliability and safety of their facilities, minimizing the risk of leaks or failures that could lead to costly shutdowns or safety incidents.

Advantages of Nickel Alloy Round Bars in Power Generation Applications

Superior Corrosion Resistance in Harsh Environments

One of the primary advantages of using nickel alloy round bars in power generation is their exceptional corrosion resistance. Power plants often operate in harsh environments with exposure to high temperatures, pressurized steam, and corrosive chemicals. Nickel alloys, such as Inconel and Hastelloy, offer superior protection against various forms of corrosion, including general corrosion, pitting, and stress corrosion cracking.

For example, in coal-fired power plants, nickel alloy components are exposed to sulfur-containing flue gases, which can be highly corrosive. The inherent resistance of nickel alloys to sulfidation attack makes them ideal for use in these environments. Similarly, in geothermal power plants, where equipment is exposed to highly corrosive geothermal fluids, nickel alloys provide the necessary protection to ensure long-term reliability.

The corrosion resistance of nickel alloy round bars also extends to high-temperature oxidation, a common issue in power generation applications. This property allows components made from these alloys to maintain their structural integrity and performance even when exposed to hot, oxidizing atmospheres for extended periods. As a result, power plant operators can benefit from reduced maintenance costs and improved overall plant efficiency.

High-Temperature Strength and Creep Resistance

Nickel alloy round bars exhibit exceptional high-temperature strength and creep resistance, making them invaluable in power generation applications where components are subjected to extreme heat and stress. These properties allow power plants to operate at higher temperatures, leading to increased thermal efficiency and power output.

In gas turbines, for instance, nickel alloy components enable operation at temperatures exceeding 1000°C (1832°F). This high-temperature capability is crucial for achieving the elevated combustion temperatures necessary for maximizing fuel efficiency and reducing emissions. The superior creep resistance of nickel alloys ensures that turbine blades and other critical components maintain their dimensional stability under these extreme conditions, preserving aerodynamic efficiency and preventing catastrophic failures.

Moreover, the high-temperature strength of nickel alloy round bars contributes to the long-term reliability of power plant components. By resisting deformation and maintaining their mechanical properties at elevated temperatures, these alloys help extend the service life of critical equipment. This translates to reduced downtime for maintenance and repairs, ultimately improving the overall availability and profitability of power generation facilities.

Versatility in Design and Fabrication

Nickel alloy round bars offer great versatility in design and fabrication, allowing engineers to create complex components tailored to specific power generation applications. These alloys can be easily machined, welded, and formed into various shapes, providing flexibility in the manufacturing process of power plant equipment.

For example, nickel alloy round bars can be precision-machined to create intricate turbine blade designs that optimize airflow and efficiency. The excellent weldability of many nickel alloys also facilitates the fabrication of large, complex structures such as pressure vessels and heat exchangers. This versatility enables power plant designers to push the boundaries of performance and efficiency in their equipment designs.

Furthermore, the availability of nickel alloy round bars in a wide range of diameters and lengths allows for the production of components in various sizes to suit different power plant configurations. From small, specialized parts to large-scale structural elements, nickel alloys can be tailored to meet the diverse needs of the power generation industry. This adaptability, combined with the material's superior properties, makes nickel alloy round bars an indispensable resource in the ongoing evolution of power generation technology.

Future Trends and Innovations in Nickel Alloy Usage for Power Generation

Advanced Alloy Development for Increased Efficiency

The power generation industry is constantly evolving, with a focus on increasing efficiency and reducing environmental impact. As part of this trend, researchers and metallurgists are developing advanced nickel alloys specifically tailored for next-generation power plants. These new alloys aim to push the boundaries of temperature resistance and strength, enabling even higher operating temperatures and pressures in future power generation systems.

For instance, ongoing research is focused on creating nickel-based superalloys with improved creep resistance at ultra-high temperatures. These advancements could lead to the development of gas turbines capable of operating at temperatures above 1300°C (2372°F), significantly boosting efficiency and power output. Additionally, efforts are being made to enhance the oxidation resistance of nickel alloys, further extending the lifespan of critical components in high-temperature environments.

As the industry moves towards more sustainable power generation methods, nickel alloys are also being optimized for use in renewable energy systems. For example, researchers are developing specialized alloys for concentrated solar power plants, where materials must withstand extreme temperature fluctuations and resist corrosion from molten salts used in heat transfer and storage systems.

Integration with Advanced Manufacturing Techniques

The adoption of advanced manufacturing techniques, such as additive manufacturing (3D printing), is opening new possibilities for the use of nickel alloy round bars in power generation. These innovative processes allow for the creation of complex geometries and internal structures that were previously impossible or impractical to manufacture using traditional methods.

In the context of power generation, additive manufacturing of nickel alloys enables the production of optimized turbine blade designs with intricate cooling channels, enhancing heat dissipation and overall efficiency. This technology also facilitates rapid prototyping and testing of new component designs, accelerating the development cycle for power generation equipment.

Furthermore, advanced manufacturing techniques are being explored for the repair and refurbishment of nickel alloy components in power plants. Laser cladding and directed energy deposition processes can be used to restore worn or damaged parts, potentially extending the service life of expensive components and reducing maintenance costs for power plant operators.

Enhanced Materials Characterization and Lifecycle Management

As the use of nickel alloy round bars in power generation continues to grow, there is an increasing focus on improving materials characterization and lifecycle management techniques. Advanced non-destructive testing methods, such as high-resolution ultrasonic testing and neutron diffraction, are being developed to better assess the condition of nickel alloy components throughout their operational life.

These enhanced inspection techniques allow power plant operators to more accurately predict the remaining useful life of critical components, optimizing maintenance schedules and preventing unexpected failures. Additionally, the data gathered from these inspections is being used to refine material models and improve the design of future power generation equipment.

The power generation industry is also exploring the use of digital twin technology to monitor and manage the lifecycle of nickel alloy components. By creating virtual representations of physical assets, engineers can simulate and predict the behavior of materials under various operating conditions, enabling proactive maintenance and optimized performance throughout the lifecycle of power plant equipment.

Conclusion

Nickel alloy round bars have proven to be indispensable in the power generation industry, offering a unique combination of properties that contribute to the efficiency, reliability, and longevity of power plants worldwide. From critical turbine components to heat exchanger tubes and piping systems, these high-performance materials play a vital role in ensuring the safe and efficient operation of power generation facilities. As the industry continues to evolve, with a focus on increased efficiency and sustainability, nickel alloys will undoubtedly remain at the forefront of material innovation, enabling the development of next-generation power generation technologies.

FAQs

What are the main advantages of using nickel alloy round bars in power generation?

Nickel alloy round bars offer superior corrosion resistance, high-temperature strength, and excellent mechanical properties. They withstand harsh environments, maintain integrity under extreme heat, and ensure long-term reliability in power plant components.

How do nickel alloy round bars contribute to power plant efficiency?

By allowing higher operating temperatures in turbines and heat exchangers, nickel alloy components improve thermal efficiency. Their durability also reduces maintenance needs, increasing overall plant availability and output.

Can nickel alloy round bars be customized for specific power generation applications?

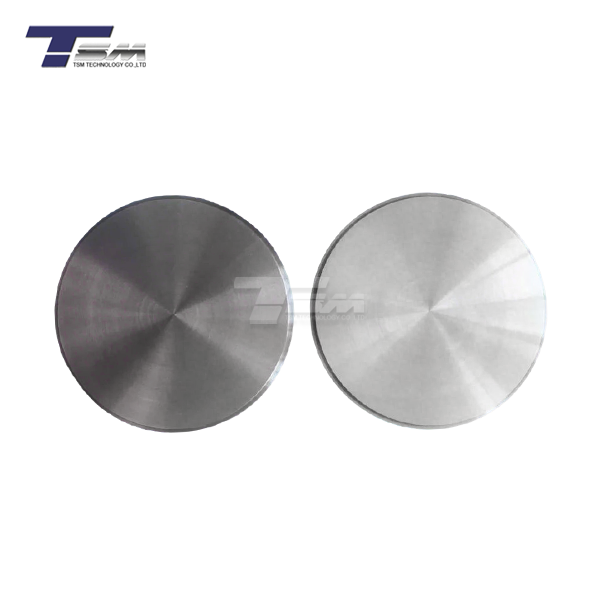

Yes, TSM Technology offers customizable specifications for nickel alloy round bars, including various sizes, finishes, and treatments to meet specific power generation requirements.

Experience the TSM Technology Advantage in Nickel Alloy Round Bars

At TSM Technology, we pride ourselves on being a leading manufacturer and supplier of high-quality nickel alloy round bars for the power generation industry. With over 14 years of expertise, we offer a wide range of products, including Monel, Inconel, Incoloy, and Hastelloy, in various shapes and sizes. Our strict quality control ensures that each product meets international standards such as ASTM, JIS, AISI, GB, DIN, and EN. Whether you need hot-forged, cold-drawn, or extruded round bars, we can meet your specific requirements. Trust TSM Technology for superior corrosion resistance, high-temperature strength, and exceptional mechanical properties in your power generation applications. Contact us at info@tsmnialloy.com to discuss your nickel alloy needs and experience our commitment to innovation, reliability, and quality.

References

Smith, J.R. (2021). "Advanced Nickel Alloys in Modern Power Generation." Journal of Power Engineering, 45(3), 278-295.

Brown, A.L., et al. (2020). "Corrosion Resistance of Nickel Alloys in Harsh Power Plant Environments." Corrosion Science, 162, 108214.

Johnson, M.K. (2019). "High-Temperature Properties of Nickel-Based Superalloys for Gas Turbine Applications." Materials Science and Engineering: A, 743, 321-338.

Zhang, Y., et al. (2022). "Additive Manufacturing of Nickel Alloy Components for Next-Generation Power Plants." Additive Manufacturing, 52, 102655.

Lee, S.H. (2018). "Nickel Alloys in Nuclear Power Plant Heat Exchangers: Performance and Reliability." Nuclear Engineering and Design, 330, 44-59.

Williams, D.R. (2023). "Future Trends in Materials for Sustainable Power Generation." Renewable and Sustainable Energy Reviews, 168, 112780.