Surface Defects: Identification and Mitigation

Surface defects can significantly impact the performance and longevity of Incoloy 825 round bars. Let's examine the most common surface issues and how to address them:

Scratches and Gouges

Scratches and gouges are mechanical imperfections that often occur during material handling, transportation, or machining operations. These defects can break the passive oxide layer of Incoloy 825, exposing the underlying metal to corrosion and creating potential stress concentration points. Over time, this can lead to fatigue cracking or localized corrosion.

Prevention:

- Implement strict handling protocols and provide training for all personnel.

- Use padded or protective packaging to minimize contact damage during transit.

- Employ precision machining tools and ensure cutting equipment is properly maintained and calibrated.

Pitting

Pitting is a localized corrosion phenomenon that develops when the protective oxide film on the Incoloy 825 surface breaks down due to contamination, improper heat treatment, or exposure to chloride-rich environments. Small pits can grow into deeper cavities, compromising the integrity of the bar and leading to potential failure under stress.

Prevention:

- Follow proper heat treatment procedures to restore the protective oxide film.

- Maintain a clean environment during fabrication, storage, and handling to prevent contamination.

- Apply corrosion-resistant coatings or surface passivation treatments when required by the service environment.

Scale Formation

Scale formation occurs during hot working or heat treatment when oxide layers build up on the surface of Incoloy 825 round bars. Excessive scaling not only affects surface finish and aesthetics but can also impair mechanical properties by introducing roughness and surface stress.

Prevention:

- Control hot working temperatures and exposure times to minimize oxidation.

- Use effective descaling methods such as pickling or mechanical brushing after heat treatment.

- Employ controlled atmosphere or vacuum furnaces to reduce oxidation during processing.

Internal Defects: Detection and Control

Internal defects in Incoloy 825 round bars can be more challenging to detect but are equally important to address. Here are some common internal issues:

Porosity

Porosity refers to the presence of small gas pockets or voids trapped within the microstructure of Incoloy 825 round bars during melting or casting. These voids can reduce mechanical integrity, lower tensile strength, and act as initiation sites for corrosion, especially in high-pressure or marine environments. Excessive porosity can also impair weld quality and dimensional accuracy.

Prevention:

- Optimize melting and casting processes to minimize gas entrapment and turbulence.

- Employ vacuum degassing or electroslag refining to eliminate dissolved gases.

- Implement thorough quality control measures such as ultrasonic or radiographic inspection during production.

Inclusions

Inclusions are non-metallic particles, such as oxides, sulfides, or silicates, that become trapped within the metal matrix during melting or refining. These inclusions can serve as stress concentration points, reducing fatigue life and acting as corrosion initiation sites under aggressive conditions. Their presence compromises the overall structural integrity of Incoloy 825 round bars.

Prevention:

- Use high-purity raw materials to reduce the risk of contamination.

- Implement effective slag control and refining techniques to remove impurities.

- Utilize advanced secondary melting processes, such as vacuum arc remelting (VAR) or electroslag remelting (ESR), to ensure a clean and homogeneous alloy structure.

Segregation

Segregation occurs when alloying elements distribute unevenly during solidification, leading to variations in mechanical and corrosion properties across the Incoloy 825 round bar. This non-uniform composition can create weak zones or areas with differing corrosion resistance, potentially compromising performance in demanding environments.

Prevention:

- Optimize solidification parameters during the casting process to promote uniform distribution of elements.

- Employ homogenization heat treatments to reduce chemical segregation and refine grain structure.

- Utilize controlled and gradual cooling rates to maintain consistent alloy properties throughout the bar.

Quality Control and Inspection Techniques

Ensuring the quality of Incoloy 825 round bars requires comprehensive inspection and testing procedures. Here are key techniques used in the industry:

Non-Destructive Testing (NDT)

NDT methods allow for thorough inspection without damaging the material. Common techniques include:

- Ultrasonic testing for internal defect detection

- Eddy current testing for surface and near-surface flaws

- Magnetic particle inspection for surface and subsurface defects

Metallographic Examination

Metallographic analysis provides insights into the microstructure of Incoloy 825 round bars, helping to identify:

- Grain size and uniformity

- Presence of unwanted phases or precipitates

- Evidence of proper heat treatment

Chemical Composition Analysis

Ensuring the correct chemical composition is crucial for maintaining the desired properties of Incoloy 825 round bars. Techniques include:

- X-ray fluorescence (XRF) spectroscopy

- Optical emission spectroscopy (OES)

- Inductively coupled plasma (ICP) analysis

By implementing rigorous quality control measures and utilizing advanced inspection techniques, manufacturers can significantly reduce the occurrence of defects in Incoloy 825 round bars. This ensures that the final product meets the stringent requirements of critical applications in corrosive environments.

Conclusion

Understanding and preventing common defects in Incoloy 825 round bars is essential for maintaining their superior performance in demanding industrial applications. By focusing on surface and internal defect prevention, implementing strict quality control measures, and utilizing advanced inspection techniques, manufacturers can ensure the production of high-quality Incoloy 825 round bars. This proactive approach not only enhances the reliability and longevity of components made from these bars but also contributes to increased safety and efficiency in critical industries such as chemical processing, oil and gas, and marine applications.

FAQs

What are the most common applications for Incoloy 825 round bars?

Incoloy 825 round bars are widely used in chemical processing equipment, oil and gas extraction, marine applications, and nuclear power plants due to their excellent corrosion resistance and mechanical properties.

How does TSM Technology ensure the quality of its Incoloy 825 round bars?

TSM Technology employs advanced production techniques, rigorous quality control measures, and comprehensive testing procedures to ensure the highest quality of Incoloy 825 round bars. Our ISO 9001 and AS9100 certifications demonstrate our commitment to excellence.

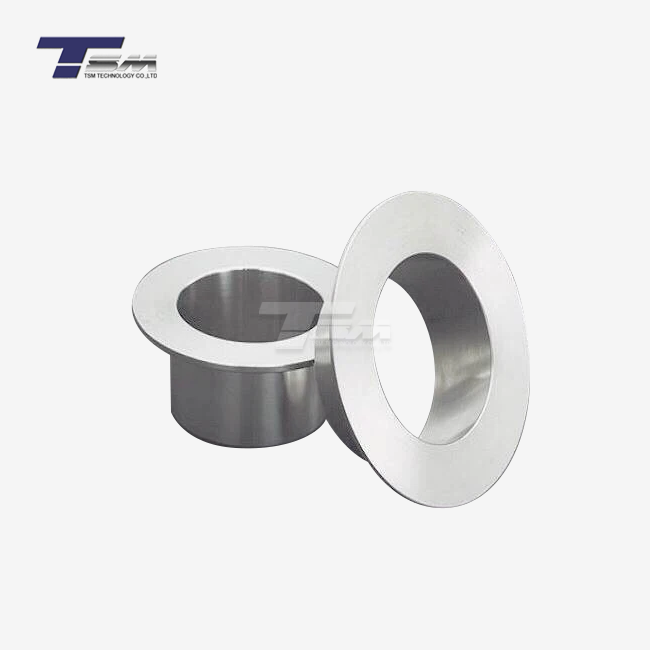

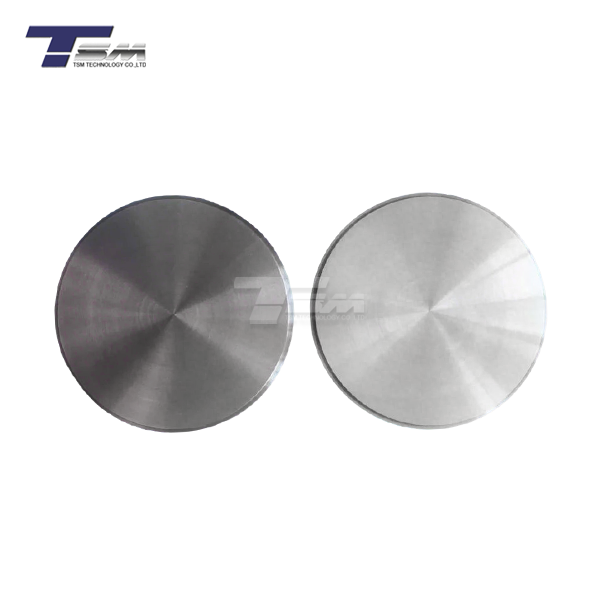

Why Choose TSM Technology for Your Incoloy 825 Round Bar Needs?

TSM Technology stands out as a premier manufacturer of Incoloy 825 round bars, offering unparalleled quality and service. With our state-of-the-art 3,200㎡ production facility, featuring vacuum arc furnaces and 2,500-ton forging presses, we ensure precision and consistency in every bar. Our extensive range of sizes (3mm to 400mm diameter) and finishes caters to diverse industry needs. Trust in our 14 years of expertise and commitment to innovation. For superior Incoloy 825 round bars that meet the most demanding standards, contact us at info@tsmnialloy.com.

References

ASTM International. (2020). "Standard Specification for Nickel-Iron-Chromium-Molybdenum-Copper Alloy (UNS N08825 and UNS N08221) Plate, Sheet, and Strip." ASTM B424-20.

ASM International. (2018). "Handbook of Corrosion-Resistant Alloys." Materials Park, OH: ASM International.

Special Metals Corporation. (2019). "Incoloy alloy 825 Technical Data Sheet." Huntington, WV: Special Metals Corporation.

Nace International. (2021). "Corrosion Prevention and Control in the Chemical Process Industries." Houston, TX: Nace International.

American Welding Society. (2017). "Welding Handbook: Materials and Applications, Part 1." Miami, FL: American Welding Society.

The International Nickel Company. (2016). "Guidelines for the Welded Fabrication of Nickel Alloys for Corrosion-Resistant Service." Toronto, Canada: The International Nickel Company.