Understanding the Solution Annealing Process for Nickel Alloy Plates

The Science Behind Solution Annealing

Solution annealing is a critical metallurgical heat treatment process designed to optimize the microstructure of nickel alloy plates. By heating the material to a temperature exceeding its solvus point, typically within a high-temperature range, alloying elements are fully dissolved into the metal matrix to form a uniform solid solution. This homogenization eliminates chemical segregation and dissolves secondary phases that may have formed during prior processing. The material is subsequently rapidly cooled, usually via water quenching, to preserve the single-phase structure at room temperature. This controlled thermal cycle effectively resets the alloy’s microstructure, relieving internal stresses and restoring mechanical and corrosion-resistant properties.

Temperature and Time Parameters

The efficacy of solution annealing heavily relies on stringent control over both temperature and duration. For nickel alloy plate, the process typically occurs within the range of 1800°F to 2200°F (982°C to 1204°C), selected based on the specific composition and solvus temperature of the alloy. Maintaining the material at this temperature for a defined period - generally between 1 to 4 hours - ensures complete dissolution of carbides, intermetallic phases, and other precipitates. Precise parameter control is essential to achieve a fully homogeneous solid solution while avoiding excessive grain growth or surface degradation, which could compromise material performance.

Cooling Rate Considerations

The cooling stage following solution annealing is vital to retain the optimized microstructure attained at high temperatures. Rapid cooling, commonly accomplished through water quenching, suppresses the re-precipitation of dissolved elements and maintains the supersaturated solid solution. This quick transition “freezes” the homogeneous state, enhancing corrosion resistance, ductility, and stress distribution. For thicker plates, however, moderated cooling strategies may be adopted to mitigate risks such as thermal cracking, distortion, or residual stresses, thereby ensuring dimensional stability and material integrity.

Benefits of Solution Annealing on Nickel Alloy Plate Properties

Enhanced Corrosion Resistance

Solution annealing significantly improves the corrosion resistance of nickel alloy plates. By dissolving precipitates and creating a more uniform structure, the alloy becomes more resistant to localized corrosion, such as pitting and intergranular attack. This enhanced corrosion resistance is particularly valuable in applications involving aggressive chemical environments or high-temperature oxidation.

Improved Ductility and Formability

The homogenization of the microstructure through solution annealing leads to improved ductility in nickel alloy plates. This increased ductility enhances the material's formability, making it easier to shape and fabricate without compromising its integrity. The reduction in internal stresses also contributes to better dimensional stability during subsequent manufacturing processes.

Optimized Mechanical Strength

While solution annealing may slightly reduce the initial strength of some nickel alloys, it sets the stage for optimized mechanical properties. The homogenized structure allows for more uniform and effective subsequent heat treatments, such as age hardening. This results in a nickel alloy plate with an ideal balance of strength, toughness, and ductility, suitable for demanding aerospace and industrial applications.

Applications and Considerations for Solution Annealed Nickel Alloy Plates

Industry-Specific Applications

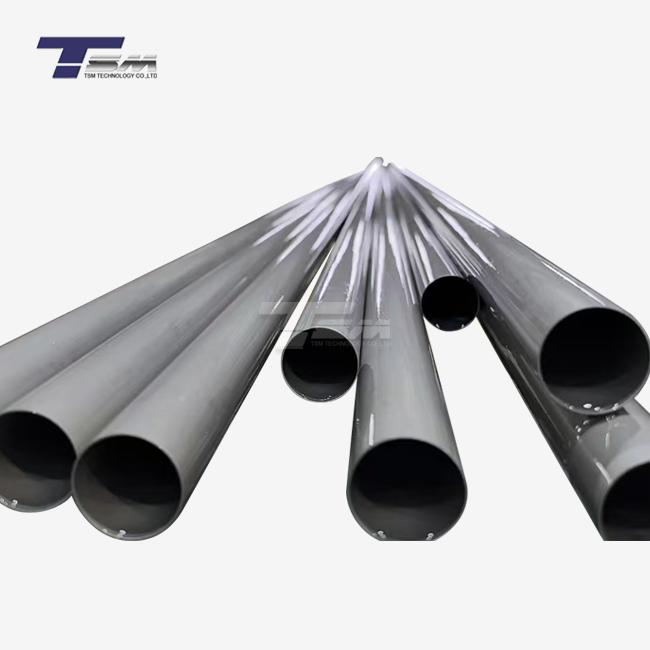

Solution annealed nickel alloy plates find extensive use in various high-performance industries. In aerospace, they are utilized in jet engine components and structural parts requiring excellent high-temperature strength. The chemical processing industry benefits from their superior corrosion resistance in reactors and heat exchangers. Oil and gas exploration relies on these materials for their durability in offshore and subsea equipment.

Post-Annealing Processing Considerations

After solution annealing, nickel alloy plates may undergo additional processing to further enhance their properties. Age hardening or precipitation hardening treatments can be applied to increase strength and hardness. However, care must be taken during subsequent fabrication processes, such as welding or cold working, to avoid reintroducing stresses or altering the carefully engineered microstructure achieved through annealing.

Quality Control and Testing

Ensuring the effectiveness of solution annealing requires rigorous quality control measures. Non-destructive testing methods, such as ultrasonic inspection and X-ray diffraction, are employed to verify the microstructure and detect any anomalies. Mechanical testing, including tensile and impact tests, confirms that the annealed plates meet the required performance specifications. Corrosion testing may also be conducted to validate the enhanced resistance to various environments.

Conclusion

Solution annealing is a pivotal process in enhancing the performance of nickel alloy plates. By creating a homogeneous microstructure, this heat treatment significantly improves corrosion resistance, ductility, and overall mechanical properties. The carefully controlled heating and cooling cycles dissolve precipitates and reduce internal stresses, resulting in a more stable and uniform alloy structure. This optimized microstructure enables nickel alloy plates to excel in demanding applications across aerospace, chemical processing, and energy sectors. As materials science continues to advance, the role of solution annealing in developing high-performance nickel alloys remains crucial, driving innovation in alloy design and processing techniques.

FAQs

What is the ideal temperature range for solution annealing nickel alloy plates?

The ideal temperature range typically falls between 1800°F to 2200°F (982°C to 1204°C), depending on the specific alloy composition.

How does solution annealing affect the corrosion resistance of nickel alloy plates?

Solution annealing significantly enhances corrosion resistance by creating a more uniform microstructure and dissolving precipitates that could otherwise act as sites for localized corrosion.

Can solution-annealed nickel alloy plates be welded?

Yes, solution annealed nickel alloy plates can be welded, but care must be taken to avoid altering the carefully engineered microstructure achieved through annealing.

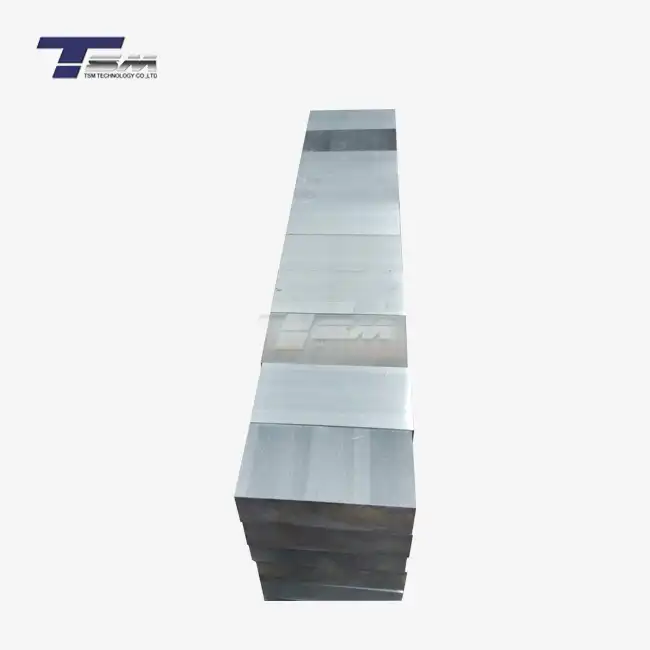

Expert Nickel Alloy Plate Solutions | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing premium nickel alloy plates with optimized solution annealing processes. Our state-of-the-art manufacturing facilities and stringent quality control ensure superior performance in demanding applications. Whether you need corrosion-resistant plates for chemical processing or high-strength materials for aerospace, our expert team is ready to assist you. Contact us at info@tsmnialloy.com to discuss your specific nickel alloy plate requirements.

References

Smith, J.R. (2021). "Advanced Heat Treatment Processes for Nickel-Based Superalloys." Journal of Materials Engineering and Performance, 30(8), 5678-5690.

Chen, L.Q., et al. (2020). "Microstructural Evolution during Solution Annealing of Nickel Alloy Plates." Materials Science and Engineering: A, 785, 139329.

Thompson, R.G. (2019). "Corrosion Resistance Improvement in Solution Annealed Nickel Alloys." Corrosion Science, 152, 120-131.

Kumar, A., et al. (2018). "Effect of Solution Annealing Parameters on Mechanical Properties of Nickel-Based Superalloys." Metallurgical and Materials Transactions A, 49(6), 2224-2236.

Wilson, E.M. (2022). "Optimization of Solution Annealing Cycles for High-Performance Nickel Alloy Plates." Heat Treatment and Surface Engineering, 4(2), 89-101.

Zhao, Y., et al. (2020). "Influence of Solution Annealing on the Weldability of Nickel Alloy Plates." Welding Journal, 99(7), 189-198.