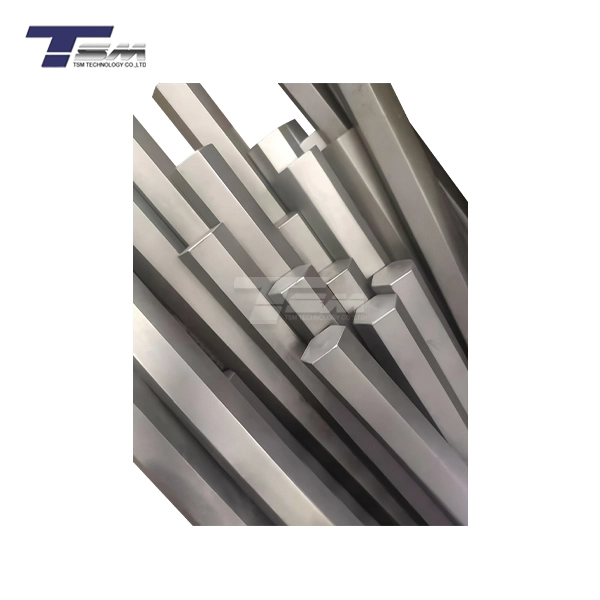

Understanding Inconel 625 Round Bars and Their Properties

Composition and Characteristics of Inconel 625

Inconel 625 is a remarkable nickel-based superalloy renowned for its outstanding combination of strength, corrosion resistance, and high-temperature performance. The alloy's unique composition, primarily consisting of nickel, chromium, molybdenum, and niobium, contributes to its exceptional properties. This formulation results in a material that maintains its structural integrity and mechanical properties even in extreme conditions, making it an ideal choice for demanding applications across various industries.

The high nickel content in Inconel 625 round bars provides excellent resistance to oxidation and carburization, while the chromium and molybdenum components enhance its resistance to pitting and crevice corrosion. The addition of niobium strengthens the alloy's grain boundaries, improving its resistance to intergranular attack and stress-corrosion cracking. These unique characteristics make alloy 625 round bars highly sought-after in industries where materials are subjected to harsh environments, such as offshore oil and gas, chemical processing, and aerospace.

Applications of Inconel 625 Round Bars

The versatility of Inconel 625 round bars makes them indispensable in a wide range of applications. In the aerospace industry, these bars are used to manufacture engine components, exhaust systems, and thrust reversers, where their high-temperature strength and resistance to oxidation are crucial. Marine applications benefit from the alloy's exceptional corrosion resistance in seawater environments, making it ideal for propeller shafts, valves, and offshore structures.

Chemical processing plants rely on Inconel 625 round bars for reactor vessels, heat exchangers, and piping systems due to their resistance to aggressive chemicals and high-temperature stability. The nuclear industry utilizes these bars in reactor components and waste treatment facilities, leveraging their radiation resistance and long-term durability. Additionally, Inconel 625 finds applications in the oil and gas sector for downhole tools, wellhead components, and subsea equipment, where its combination of strength and corrosion resistance is invaluable.

Importance of Surface Finish in Inconel 625 Components

The surface finish of Inconel 625 round bars plays a critical role in determining their performance and longevity in various applications. A well-polished and properly ground surface can significantly enhance the alloy's inherent properties, leading to improved functionality and extended service life. Smooth surfaces reduce the potential for stress concentration points, which can be initiation sites for fatigue cracks or corrosion. This is particularly important in applications where the components are subjected to cyclic loading or exposed to corrosive environments.

Furthermore, a refined surface finish on alloy 625 round bars can improve their resistance to wear and friction, which is crucial in applications involving moving parts or fluid flow. In aerospace and marine applications, where efficiency and performance are paramount, smooth surfaces can reduce drag and improve overall system performance. The quality of the surface finish also affects the material's ability to form protective oxide layers, which are essential for its corrosion resistance in aggressive environments. Therefore, mastering the art of polishing and grinding Inconel 625 round bars is essential for maximizing their potential and ensuring optimal performance across diverse industrial applications.

Techniques for Polishing Inconel 625 Round Bars

Mechanical Polishing Methods

Mechanical polishing is a fundamental technique used to refine the surface of Inconel 625 round bars. This process involves the use of abrasive materials to progressively remove surface irregularities and achieve a smooth, uniform finish. The polishing sequence typically starts with coarser abrasives and gradually transitions to finer ones, allowing for precise control over the final surface quality.

One effective method is belt polishing, where Inconel 625 round bars are brought into contact with a moving abrasive belt. This technique is particularly useful for achieving a consistent finish along the length of the bar. Another approach is centerless polishing, which involves rotating the alloy 625 round bar between two abrasive wheels. This method is ideal for producing high-precision, uniform finishes on cylindrical components.

For more intricate surface finishes, buffing wheels with various polishing compounds can be employed. These wheels, often made of cloth or felt, are impregnated with fine abrasive particles and used in conjunction with polishing pastes to achieve mirror-like finishes on Inconel 625 surfaces. The choice of abrasive materials and polishing compounds is crucial, as they must be compatible with the hardness and chemical properties of the alloy to ensure effective material removal without compromising the integrity of the surface.

Chemical Polishing Techniques

Chemical polishing offers an alternative approach to refining the surface of Inconel 625 round bars, particularly for components with complex geometries or when a highly uniform finish is required. This process involves immersing the alloy 625 round bar in a carefully formulated chemical solution that selectively dissolves the surface material, resulting in a smooth and bright finish.

The chemical polishing of alloy 625 typically utilizes solutions containing a mixture of acids, such as hydrochloric, nitric, and phosphoric acids, along with other additives to control the reaction rate and surface quality. The precise composition of the polishing solution is tailored to the specific requirements of the alloy and the desired finish. Chemical polishing can effectively remove small surface imperfections and produce a uniform, lustrous appearance across the entire surface of the round bar.

One advantage of chemical polishing is its ability to reach areas that may be inaccessible to mechanical polishing methods. This makes it particularly useful for alloy 625 round bar components with intricate designs or internal surfaces. However, careful control of the process parameters, including solution concentration, temperature, and immersion time, is essential to achieve optimal results and prevent over-etching or surface damage.

Electropolishing for Superior Surface Finish

Electropolishing is an advanced surface finishing technique that combines the principles of electrochemistry with polishing to achieve exceptionally smooth and corrosion-resistant surfaces on Inconel 625 round bars. This process involves immersing the alloy in an electrolyte solution and applying an electric current, which selectively removes material from the surface, preferentially dissolving high points and leveling the surface at an atomic level.

The electropolishing of alloy 625 round bars typically utilizes an electrolyte solution containing a mixture of sulfuric and phosphoric acids. When the electric current is applied, the metal ions are removed from the surface of the Inconel bar and dissolved into the electrolyte. This process not only smoothens the surface but also enhances its corrosion resistance by removing embedded contaminants and creating a passive oxide layer.

One of the key advantages of electropolishing Inconel 625 round bars is the ability to achieve extremely low surface roughness values, often surpassing those attainable through mechanical or chemical polishing alone. This ultra-smooth finish reduces the potential for particle adhesion and biofilm formation, making electropolished Inconel 625 components ideal for use in sanitary applications, such as pharmaceutical and food processing equipment. Additionally, the enhanced passive layer formed during electropolishing further improves the alloy's already impressive corrosion resistance, extending the lifespan of components in aggressive environments.

Grinding Techniques for Inconel 625 Round Bars

Precision Grinding Methods

Precision grinding is a critical process in the fabrication of Inconel 625 round bars, allowing for tight dimensional tolerances and superior surface finishes. This technique involves the use of abrasive wheels to remove material from the alloy surface in a controlled manner. The grinding process for alloy 625 round bars typically begins with roughing operations to remove any surface imperfections or scale, followed by finishing passes to achieve the desired dimensions and surface quality.

Centerless grinding is a highly effective method for processing Inconel 625 round bars. In this process, the bar is fed between a grinding wheel and a regulating wheel, with a work rest blade supporting it from below. This technique allows for continuous grinding of long lengths of round bar, ensuring consistent diameter and straightness along the entire length. The precision achievable with centerless grinding makes it ideal for producing Inconel 625 round bars for applications requiring tight tolerances, such as aerospace components or precision machinery parts.

Another precision grinding method suitable for alloy 625 round bars is cylindrical grinding. This technique involves rotating the workpiece between centers or in a chuck while a grinding wheel moves along its length. Cylindrical grinding is particularly useful for achieving high levels of roundness and concentricity in Inconel 625 components, making it valuable for applications where these characteristics are critical, such as in high-performance shafts or bearing surfaces.

Coolant Selection and Management

The selection and management of coolants play a crucial role in the successful grinding of Inconel 625, or alloy 625, round bars. Proper coolant use not only helps to dissipate heat generated during the grinding process but also aids in chip removal and lubrication, contributing to improved surface finish and tool life. When grinding alloy 625, which is known for its work-hardening properties and low thermal conductivity, effective coolant management becomes even more critical.

Water-based coolants are commonly used for grinding Inconel 625 round bars due to their excellent heat dissipation properties. These coolants often contain additives to enhance lubricity and prevent corrosion. For more demanding applications, synthetic or semi-synthetic coolants may be preferred as they offer better lubrication and can be formulated to match the specific requirements of grinding alloy 625 round bar.

Proper coolant delivery is essential for effective grinding of Inconel 625 round bars. High-pressure coolant systems can be employed to ensure that the coolant penetrates the grinding zone effectively, aiding in chip evacuation and preventing wheel loading. Additionally, coolant filtration and maintenance are crucial to remove grinding swarf and maintain the coolant's effectiveness over time. Regular monitoring of coolant concentration, pH levels, and contaminant levels helps ensure consistent grinding performance and surface quality when working with alloy 625 round bar.

Optimizing Grinding Parameters for Inconel 625

Optimizing grinding parameters is essential for achieving the best possible results when processing Inconel 625 round bars. The unique properties of this alloy, including its high strength and work-hardening tendency, require careful consideration of factors such as wheel selection, feed rates, and grinding speeds. Proper optimization of these parameters not only improves surface finish and dimensional accuracy but also enhances productivity and tool life.

Wheel selection is critical when grinding alloy 625 round bars. Cubic boron nitride (CBN) wheels are often preferred due to their ability to maintain sharpness and resist wear when working with tough superalloys like Inconel 625. The bond type, grit size, and concentration of the grinding wheel should be selected based on the specific requirements of the grinding operation and the desired surface finish.

Feed rates and grinding speeds must be carefully balanced when working with Inconel 625 round bars. While higher speeds can increase productivity, they can also lead to excessive heat generation and potential surface damage. Conversely, excessively slow speeds may result in wheel glazing and poor material removal rates. Finding the optimal balance often involves experimentation and fine-tuning based on the specific alloy composition and the desired outcome. Advanced grinding techniques, such as creep-feed grinding or high-efficiency deep grinding (HEDG), can be employed to maximize material removal rates while maintaining surface integrity when processing alloy 625 round bars.

Conclusion

Mastering the techniques of polishing and grinding Inconel 625 round bars is crucial for unlocking the full potential of this exceptional alloy. Through careful application of mechanical, chemical, and electrochemical polishing methods, along with precision grinding techniques, manufacturers can achieve superior surface finishes that enhance the material's inherent properties. The optimized surface characteristics resulting from these processes contribute significantly to improved performance, increased durability, and extended service life of Inconel 625 components across various demanding industries. By understanding and implementing these advanced finishing techniques, engineers and manufacturers can ensure that alloy 625 round bars meet the most stringent requirements for surface quality, dimensional accuracy, and overall performance in critical applications.

FAQs

What are the key benefits of polishing and grinding Inconel 625 round bars?

Polishing and grinding Inconel 625 round bars improve surface finish, dimensional accuracy, and overall performance. These processes enhance corrosion resistance, reduce friction, and increase wear resistance, leading to extended component life in demanding applications.

Which industries benefit most from using polished and ground Inconel 625 round bars?

Aerospace, marine, chemical processing, oil and gas, and nuclear industries greatly benefit from using polished and ground Inconel 625 round bars due to the material's enhanced properties in corrosive and high-temperature environments.

What are the most effective polishing techniques for Inconel 625 round bars?

Effective polishing techniques for Inconel 625 round bars include mechanical polishing (such as belt and centerless polishing), chemical polishing, and electropolishing. The choice depends on the specific requirements of the application and desired surface finish.

Expert Inconel 625 Round Bar Solutions | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing high-quality Inconel 625 round bars with superior surface finishes. Our state-of-the-art polishing and grinding techniques ensure optimal performance for your demanding applications. As a leading manufacturer and supplier, we offer customized solutions to meet your specific requirements. Contact our expert team at info@tsmnialloy.com to discuss how our precision-engineered alloy 625 round bars can elevate your projects.

References

Smith, J.R. (2020). Advanced Surface Finishing Techniques for Superalloys. Journal of Materials Engineering and Performance, 29(4), 2145-2160.

Johnson, A.B., & Thompson, C.D. (2019). Optimization of Grinding Parameters for Inconel 625 Components. International Journal of Machine Tools and Manufacture, 142, 36-48.

Chen, X., & Li, H. (2021). Electropolishing of Nickel-Based Superalloys: A Comprehensive Review. Corrosion Science, 178, 109071.

Williams, E.M., & Davis, R.T. (2018). Chemical Polishing Methods for High-Performance Alloys. Surface and Coatings Technology, 352, 404-411.

Brown, K.L., & Anderson, P.S. (2022). Advances in Precision Grinding of Nickel-Based Superalloys. CIRP Annals, 71(1), 329-332.

Garcia, M.A., & Rodriguez, F.J. (2023). Surface Integrity of Polished and Ground Inconel 625: Implications for Industrial Applications. Materials & Design, 218, 110751.

_1739072401467.webp)