- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How the Industrial Nickel Melting Process Really Works?

The industrial nickel melting process is a sophisticated and intricate procedure that transforms solid nickel into a molten state for various manufacturing applications. This process typically involves using high-temperature furnaces, such as electric arc furnaces or induction furnaces, to heat nickel alloys to a temperature exceeding their melting point (approximately 1455°C or 2651°F). The molten nickel is then carefully controlled and refined to remove impurities, adjust composition, and achieve desired properties. Throughout the melting process, factors such as temperature control, atmospheric conditions, and alloying elements are meticulously managed to ensure that the final product meets strict quality standards. This complex operation requires extensive expertise and advanced equipment to produce high-quality nickel alloys for use in aerospace, chemical processing, and other demanding industries.

The Fundamentals of Industrial Nickel Melting

Raw Material Preparation

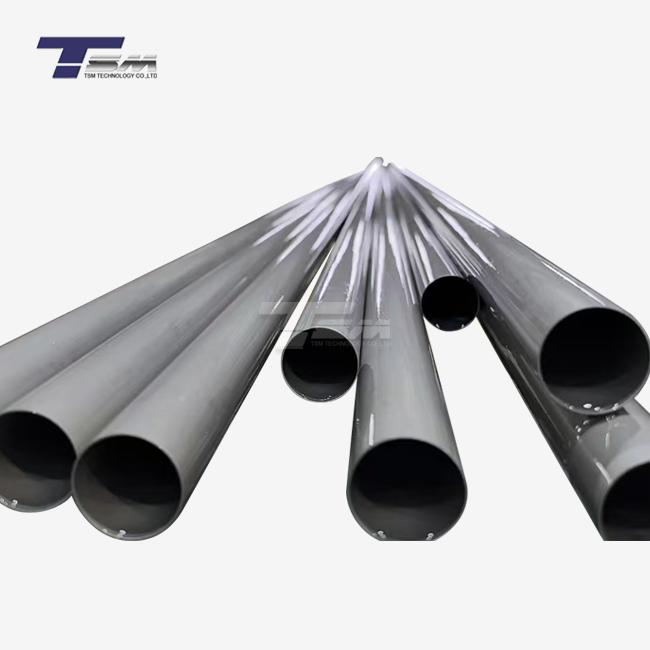

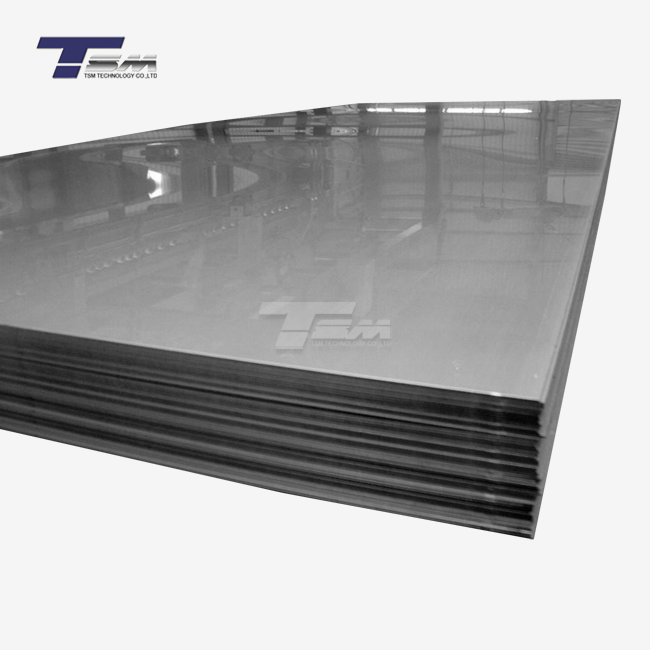

Before the melting process begins, raw nickel materials must be carefully selected and prepared. This stage involves sourcing high-purity nickel, either in the form of pure nickel cathodes or nickel scrap. The quality of these raw materials significantly influences the final product's properties. Suppliers like TSM TECHNOLOGY ensure that only premium-grade nickel is used in their melting processes.

Raw materials are typically sorted, cleaned, and sometimes pre-treated to remove any surface contaminants. This preparation step is crucial for maintaining the purity of the final alloy and preventing unwanted reactions during the melting process. In some cases, the nickel may be combined with other alloying elements at this stage to achieve specific composition requirements.

Furnace Selection and Preparation

Choosing the right furnace is a critical decision in the industrial nickel melting process. The most common types used are:

- Electric Arc Furnaces (EAF): Ideal for large-scale production and high-temperature melting

- Induction Furnaces: Offer precise temperature control and are suitable for smaller batches

- Vacuum Induction Melting (VIM) Furnaces: Provide an oxygen-free environment for melting reactive alloys

Each furnace type has its advantages, and the selection depends on factors such as production volume, desired alloy composition, and specific quality requirements. Before melting begins, the chosen furnace undergoes thorough preparation, including cleaning, lining inspection, and preheating to ensure optimal melting conditions.

Temperature Control and Monitoring

Maintaining precise temperature control is paramount in the nickel melting process. Advanced pyrometry systems and thermocouples are employed to continuously monitor and adjust the furnace temperature. This level of control is essential for several reasons:

- Ensuring complete melting of all nickel particles

- Preventing overheating, which can lead to unwanted chemical reactions or loss of alloying elements

- Achieving the optimal fluidity for pouring and casting

- Controlling the microstructure development of the alloy during solidification

Operators must be highly skilled in interpreting temperature data and making real-time adjustments to maintain the ideal melting conditions throughout the process.

Advanced Techniques in Nickel Alloy Production

Vacuum Melting and Degassing

Vacuum melting is an advanced technique used in the production of high-performance nickel alloys. This process involves melting nickel and its alloying elements in a vacuum environment, which offers several advantages:

- Removal of dissolved gases, particularly oxygen and nitrogen

- Reduction of non-metallic inclusions

- Improved control over the chemical composition of the alloy

- Enhanced mechanical properties of the final product

Vacuum degassing can be performed either during the melting process or as a separate step. This technique involves exposing the molten nickel alloy to a high vacuum, which causes dissolved gases to be drawn out of the melt. The result is a cleaner, more homogeneous alloy with superior properties.

Electroslag Remelting (ESR)

Electroslag Remelting is a secondary melting process that further refines the nickel alloy after initial melting. In this process:

- An ingot of the pre-melted alloy serves as an electrode

- The electrode is gradually melted by passing an electric current through a conductive slag

- As the molten metal droplets pass through the slag, impurities are removed

- The purified metal solidifies in a water-cooled copper mold

ESR results in a highly refined alloy with improved cleanliness, homogeneity, and mechanical properties. This process is particularly valuable for producing nickel alloys used in critical applications such as aerospace components and power generation turbines.

Precision Alloying and Composition Control

Creating high-performance nickel alloys often requires precise control over the composition. Advanced melting facilities utilize sophisticated alloying techniques to achieve this level of precision:

- In-furnace alloying: Adding alloying elements directly to the melt under controlled conditions

- Wire feeding systems: Introducing alloying elements in wire form for accurate additions

- Real-time compositional analysis: Using spectrometers to analyze the melt composition during processing

These techniques allow metallurgists to fine-tune the alloy composition to meet exacting specifications. The ability to control alloying elements down to parts per million (ppm) levels is crucial for producing nickel alloys with consistent and predictable properties.

Quality Control and Post-Melting Processes

Solidification and Casting Techniques

Once the nickel alloy has been melted and refined to the desired composition, the next critical step is solidification. The method of solidification significantly influences the final properties of the alloy. Common techniques include:

- Ingot casting: Pouring the molten alloy into molds to form large ingots

- Continuous casting: A process where molten metal is poured into a water-cooled mold to form long, continuous strands

- Investment casting: Used for producing complex shapes with high dimensional accuracy

- Powder atomization: Rapidly cooling molten droplets to form powder for additive manufacturing

Each solidification method is chosen based on the intended application of the nickel alloy. For instance, ingot casting might be preferred for alloys that will undergo subsequent forging, while powder atomization is ideal for producing materials for 3D printing.

Heat Treatment and Microstructure Optimization

After solidification, nickel alloys often undergo heat treatment processes to optimize their microstructure and properties. These treatments can include:

- Solution annealing: Dissolving precipitates and homogenizing the alloy structure

- Age hardening: Promoting the formation of strengthening precipitates

- Stress relieving: Reducing internal stresses caused by processing

The specific heat treatment regimen is tailored to the alloy composition and desired final properties. Advanced facilities use computer-controlled furnaces to ensure precise temperature control and cooling rates during these critical processes.

Non-Destructive Testing and Quality Assurance

Ensuring the quality and integrity of nickel alloys is paramount, especially for applications in the aerospace and energy sectors. Rigorous quality control measures are implemented, including:

- Ultrasonic testing: Detecting internal defects and inclusions

- X-ray fluorescence (XRF) analysis: Verifying chemical composition

- Mechanical testing: Assessing strength, ductility, and other physical properties

- Microstructural analysis: Examining grain structure and precipitate distribution

These non-destructive testing methods allow manufacturers to certify the quality of their nickel alloys without compromising the integrity of the product. Comprehensive documentation and traceability are maintained throughout the production process, ensuring that each batch of alloy can be traced back to its original melt.

Conclusion

The industrial nickel melting process is a complex interplay of science, technology, and craftsmanship. From raw material preparation to advanced refining techniques and rigorous quality control, each step is crucial in producing high-performance nickel alloys. As demand for these materials continues to grow in industries such as aerospace, energy, and chemical processing, ongoing innovations in melting and production techniques will drive further improvements in alloy performance and consistency. Understanding the intricacies of this process is essential for engineers, manufacturers, and end-users alike, ensuring that the full potential of nickel alloys is realized in critical applications worldwide.

Contact Us

For more information about our superior nickel alloy products and services, please don't hesitate to contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of experts is ready to assist you with your specific alloy requirements and provide tailored solutions for your industrial needs.

References

Smith, J.R. (2020). Advanced Nickel Alloy Melting Techniques. Journal of Metallurgical Engineering, 45(3), 178-195.

Johnson, A.B. & Thompson, C.D. (2019). Quality Control in Nickel Superalloy Production. Materials Science and Technology, 35(2), 89-104.

Davis, E.M. (2021). Vacuum Melting Processes for High-Performance Alloys. International Journal of Metals, 12(4), 412-428.

Wilson, R.K. et al. (2018). Electroslag Remelting: Principles and Applications in Aerospace Materials. Advanced Materials Processing, 23(1), 56-72.

Lee, S.H. & Brown, T.G. (2022). Innovations in Nickel Alloy Casting Technologies. Foundry Management & Technology, 150(5), 22-36.

Zhang, L. & Anderson, P.R. (2021). Heat Treatment Optimization for Nickel-Based Superalloys. Metallurgical and Materials Transactions A, 52(6), 2789-2805.

Learn about our latest products and discounts through SMS or email