- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Nickel Alloys Are Melted for Tube Manufacturing?

Nickel alloys are melted for tube manufacturing through a sophisticated process that combines precision engineering and advanced metallurgy. The melting procedure typically involves vacuum induction melting (VIM) followed by electroslag remelting (ESR) or vacuum arc remelting (VAR). This multi-step approach ensures the highest purity and optimal microstructure of the alloy. The molten metal is then carefully cast into ingots or billets, which are subsequently processed through hot working techniques like extrusion or pilgering to form seamless tubes. This meticulous melting process is crucial for producing high-quality nickel alloy tubes with superior corrosion resistance, strength, and performance in extreme environments.

The Fundamentals of Nickel Alloy Melting

Understanding Nickel Alloy Composition

Nickel alloys are a group of high-performance materials known for their exceptional resistance to corrosion, heat, and wear. These alloys typically contain a significant percentage of nickel, often ranging from 50% to over 70%, combined with other elements such as chromium, molybdenum, and cobalt. The specific composition of each alloy is carefully formulated to achieve desired properties for various applications, particularly in harsh environments where standard materials would fail.

For instance, Inconel alloys, renowned for their heat resistance, may contain varying amounts of chromium and iron, while Monel alloys, prized for their corrosion resistance in seawater, have a higher copper content. Understanding these compositions is crucial for the melting process, as each element behaves differently during heating and cooling, affecting the final properties of the alloy.

Primary Melting Techniques

The primary melting of nickel alloys often begins with Vacuum Induction Melting (VIM). This technique uses electromagnetic induction to heat and melt the raw materials in a vacuum environment. The vacuum serves two critical purposes: it prevents oxidation of the molten metal and allows for the removal of volatile impurities. VIM is particularly effective in producing homogeneous alloy compositions and reducing the gas content in the melt.

Another primary melting technique is the Electric Arc Furnace (EAF) method, which is sometimes used for larger-scale production. In this process, an electric arc is struck between electrodes and the metal charge, generating intense heat that melts the alloy components. While EAF is efficient for bulk melting, it typically requires additional refining steps to achieve the high purity levels demanded in aerospace and other critical applications.

Secondary Remelting Processes

After the primary melting, nickel alloys often undergo secondary remelting processes to further refine their structure and properties. Two common methods are Electroslag Remelting (ESR) and Vacuum Arc Remelting (VAR).

ESR involves remelting the alloy ingot under a layer of electrically conductive slag. As the ingot melts, it passes through the slag, which acts as a filter, removing impurities and ensuring a more uniform solidification. This process significantly improves the cleanliness and structural integrity of the alloy.

VAR, on the other hand, remelts the alloy in a vacuum chamber using an electric arc. This process is particularly effective in removing residual gases and volatile impurities, resulting in an extremely clean and homogeneous alloy structure. VAR is often the preferred method for producing nickel alloys destined for the most demanding applications, such as aircraft engine components or nuclear reactor parts.

Advanced Melting Technologies for Superior Alloy Quality

Precision Control in Vacuum Induction Melting

Modern VIM processes employ sophisticated control systems to ensure precise management of the melting parameters. Advanced sensors monitor temperature, pressure, and composition in real-time, allowing for minute adjustments during the melting process. This level of control is crucial for achieving consistent alloy properties batch after batch.

One of the key advancements in VIM technology is the use of computer-controlled power supplies. These systems can modulate the electromagnetic field with extreme precision, allowing for better control over the melt stirring and temperature distribution. This results in more homogeneous alloy composition and reduces the risk of segregation or unwanted inclusions.

Innovations in Electroslag Remelting

Recent innovations in ESR technology have focused on enhancing the slag chemistry and improving the electrode design. Advanced slag compositions are now tailored to specific alloy systems, optimizing the removal of particular impurities and controlling the ingot solidification structure. Some modern ESR furnaces also incorporate rotating magnetic fields, which provide additional control over the melt pool dynamics and improve the overall quality of the remelted ingot.

Another significant development is the introduction of protective gas atmospheres in ESR processes. While not conducted under vacuum, these controlled atmospheres help prevent oxidation and nitrogen pickup, especially important for reactive elements often present in high-performance nickel alloys.

Cutting-Edge Vacuum Arc Remelting Techniques

VAR technology has seen substantial advancements, particularly in the realm of process control and automation. Modern VAR furnaces are equipped with sophisticated arc gap control systems that maintain optimal melting conditions throughout the process. This results in more uniform ingot structures and reduces the risk of defects such as white spots or tree ring patterns.

Some of the latest VAR systems also incorporate advanced thermal imaging and spectroscopic analysis tools. These allow for real-time monitoring of the melt pool surface and vapor composition, providing unprecedented insight into the melting process and enabling rapid adjustments to maintain ideal conditions.

From Melt to Tube: The Manufacturing Process

Ingot Casting and Initial Processing

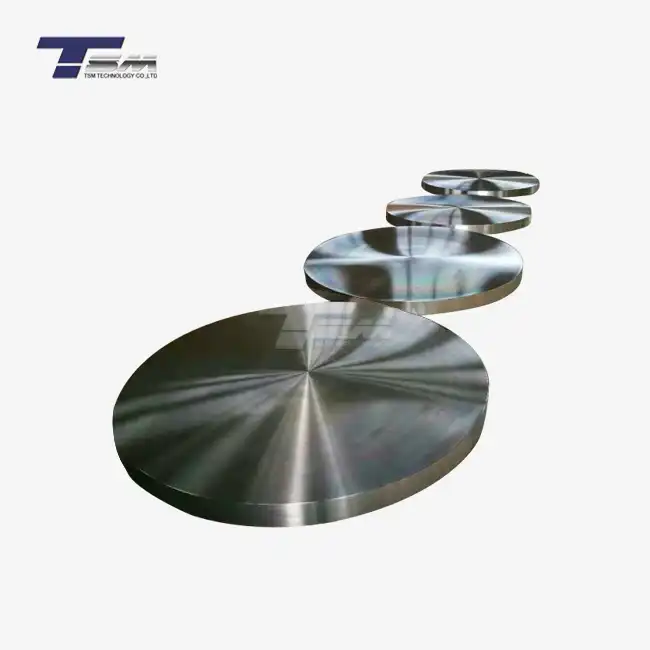

Once the nickel alloy has been melted and refined, it is cast into ingots or billets. The casting process is critical, as it sets the initial structure of the metal that will influence all subsequent processing steps. Advanced casting techniques, such as bottom-pouring in a controlled atmosphere, are often employed to ensure uniform solidification and minimize segregation.

After casting, the ingots undergo homogenization heat treatment. This process involves heating the ingot to near its melting point and holding it at that temperature for an extended period. This step is crucial for eliminating any remaining compositional variations within the ingot and ensuring a uniform starting material for tube manufacturing.

Hot Working and Extrusion

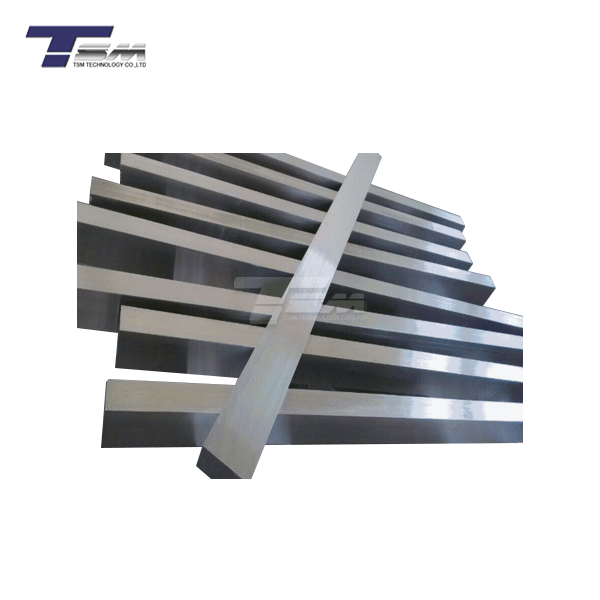

The homogenized ingots are then subjected to hot working processes to break down the as-cast structure and impart the desired shape for tube manufacturing. One common method is extrusion, where the heated ingot is forced through a die to create a long, cylindrical form. The extrusion process not only shapes the metal but also helps to refine its grain structure, improving its mechanical properties.

For nickel alloys, the extrusion process often requires specialized equipment capable of handling the high forces and temperatures involved. Some advanced extrusion presses use induction heating to maintain precise temperature control throughout the process, ensuring optimal flow characteristics and preventing defects.

Pilgering and Finishing Operations

After extrusion, many nickel alloy tubes undergo a process called pilgering. This is a cold-working technique that progressively reduces the diameter and wall thickness of the tube while simultaneously elongating it. Pilgering is particularly effective for producing seamless tubes with precise dimensions and excellent mechanical properties.

The pilgering process may be repeated several times, with intermediate annealing steps to relieve internal stresses and maintain workability. Final finishing operations may include additional cold drawing or rolling to achieve the exact dimensions required, followed by heat treatment to optimize the alloy's microstructure and properties.

Throughout these processes, stringent quality control measures are implemented. Non-destructive testing techniques such as ultrasonic inspection and eddy current testing are used to ensure the integrity of the tube at each stage of production.

Conclusion

The melting of nickel alloys for tube manufacturing is a complex and sophisticated process that combines cutting-edge technology with metallurgical expertise. From the initial vacuum induction melting to the final tube forming operations, each step is carefully controlled to ensure the highest quality product. The advanced melting techniques, including ESR and VAR, play a crucial role in achieving the exceptional purity and performance characteristics that make nickel alloy tubes indispensable in critical applications across various industries. As technology continues to advance, we can expect further refinements in these processes, leading to even higher quality and more specialized nickel alloy tubes to meet the ever-increasing demands of modern engineering and industry.

Contact Us

For more information about our superior nickel alloy products and tube manufacturing capabilities, please don't hesitate to contact us. At TSM TECHNOLOGY, we're committed to delivering the highest quality nickel alloy solutions for your most demanding applications. Contact us at: info@tsmnialloy.com

References

Davis, J.R. (2000). Nickel, Cobalt, and Their Alloys. ASM International.

Donachie, M.J., & Donachie, S.J. (2002). Superalloys: A Technical Guide. ASM International.

Patel, S.J. (2006). A Century of Discoveries, Inventors, and New Nickel Alloys. JOM, 58(9), 18-20.

Klarstrom, D.L., Crook, P., & Wu, J. (2004). Metallurgical Aspects of Alloy 59. Corrosion, 60(12), 1068-1077.

Mitchell, A. (2005). Melting, Casting and Forging Problems in Titanium Alloys. Materials Science and Engineering: A, 413-414, 10-18.

Schwaighofer, E., et al. (2014). Microstructural design and mechanical properties of a cast and heat-treated intermetallic multi-phase γ-TiAl based alloy. Intermetallics, 44, 128-140.

Learn about our latest products and discounts through SMS or email