The Importance of Low Sulfur and Phosphorus in Inconel 625

Impact on Corrosion Resistance

Sulfur and phosphorus are considered detrimental elements in Inconel 625, particularly when it comes to corrosion resistance. These impurities can form segregates or inclusions within the alloy matrix, creating weak points that are susceptible to localized corrosion. In high-temperature environments or aggressive chemical settings, even small amounts of sulfur and phosphorus can significantly compromise the alloy's performance.

Inconel 625 round bars with low sulfur and phosphorus content exhibit superior resistance to pitting, crevice corrosion, and stress corrosion cracking. This enhanced corrosion resistance is crucial for applications in marine environments, chemical processing plants, and offshore oil and gas installations where exposure to harsh conditions is common.

Influence on Mechanical Properties

The presence of sulfur and phosphorus can also negatively affect the mechanical properties of Inconel 625. These elements tend to segregate at grain boundaries, potentially leading to embrittlement and reduced ductility. By minimizing sulfur and phosphorus content, manufacturers can ensure that alloy 625 round bars maintain their excellent strength, toughness, and fatigue resistance across a wide range of temperatures.

Low levels of these impurities contribute to improved weldability and formability, making Inconel 625 more versatile for various fabrication processes. This is particularly important for components that require complex shaping or joining methods, such as those used in aerospace and power generation industries.

Enhancing Long-term Performance

Achieving low sulfur and phosphorus content in Inconel 625 is not just about meeting initial specifications; it's about ensuring long-term performance and reliability. In critical applications where failure is not an option, such as in nuclear reactors or chemical processing equipment, the purity of the alloy plays a vital role in extending service life and reducing maintenance costs.

Inconel 625 round bars with minimal impurities demonstrate better resistance to thermal cycling and creep, maintaining their structural integrity over extended periods of high-temperature operation. This translates to increased safety, reduced downtime, and improved overall efficiency in industrial processes.

Advanced Manufacturing Techniques for Low Impurity Inconel 625

Raw Material Selection and Preparation

The journey to producing high-purity Inconel 625 begins with the careful selection of raw materials. Premium-grade nickel, chromium, molybdenum, and other alloying elements are sourced from reputable suppliers who can guarantee low levels of sulfur and phosphorus. These raw materials undergo rigorous quality checks and may be subjected to pre-treatment processes to further reduce impurities.

Advanced spectrometric analysis techniques are employed to verify the composition of incoming materials, ensuring that only the highest quality feedstock is used in the production of Inconel 625 round bars and other forms. This meticulous approach to raw material management sets the foundation for achieving the desired low sulfur and phosphorus content in the final product.

Vacuum Induction Melting (VIM)

Vacuum Induction Melting is a critical primary melting process used in the production of high-purity Inconel 625 for alloy 625 round bars. This technique involves melting the alloy constituents in a vacuum environment, which significantly reduces the risk of contamination from atmospheric gases and other impurities. The absence of oxygen during melting also helps prevent the formation of oxide inclusions that could compromise the alloy's properties.

During VIM, precise control over temperature and composition allows metallurgists to fine-tune the alloy chemistry. Advanced monitoring systems and computer-controlled processes ensure that the melt meets the stringent requirements for Inconel 625, including the target levels for sulfur and phosphorus. The resulting ingot serves as a high-quality starting material for further processing into alloy 625 round bars.

Secondary Remelting Techniques

To further reduce sulfur and phosphorus levels and improve the overall quality of Inconel 625, secondary remelting processes are employed. Two common techniques are Electroslag Remelting (ESR) and Vacuum Arc Remelting (VAR).

ESR involves remelting the VIM ingot under a layer of reactive slag, which helps remove residual impurities and inclusions. The process results in a more homogeneous structure and further reduces sulfur and phosphorus content. VAR, on the other hand, remelts the alloy in a vacuum, using an electric arc. This process not only removes volatile impurities but also improves the ingot's solidification structure, leading to enhanced mechanical properties in the final Inconel 625 round bar products.

Quality Control and Testing for Inconel 625 Purity

In-Process Monitoring and Control

Throughout the manufacturing process of Inconel 625 round bars, continuous monitoring and control measures are implemented to ensure consistent purity levels. Advanced sensors and real-time analysis techniques allow for immediate adjustments to process parameters, maintaining optimal conditions for low sulfur and phosphorus content.

Metallurgists employ sophisticated modeling software to predict and control the segregation behavior of impurities during solidification. This proactive approach helps in achieving a more uniform distribution of elements throughout the alloy, minimizing the risk of localized high-impurity regions that could compromise performance.

Post-Production Testing and Verification

Once the Inconel 625 round bars are produced, they undergo a battery of tests to verify their composition and properties. High-precision analytical techniques such as Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and Glow Discharge Mass Spectrometry (GDMS) are used to accurately measure sulfur and phosphorus levels, often detecting concentrations down to parts per million.

Mechanical testing, including tensile strength, yield strength, and elongation measurements, is conducted to ensure that the low impurity levels translate into the desired performance characteristics. Corrosion testing in simulated service environments provides further validation of the alloy's resistance to degradation under challenging conditions.

Certification and Documentation

The final step in ensuring the quality of low sulfur and phosphorus Inconel 625 is comprehensive certification and documentation. Each batch of alloy 625 round bars is accompanied by detailed test reports and material certifications that attest to its composition, mechanical properties, and conformance to international standards.

This documentation not only assures customers but also enables traceability throughout the supply chain. In industries where material integrity is paramount, such as aerospace and nuclear power, this level of quality assurance is essential for regulatory compliance and risk management.

Conclusion

Achieving low sulfur and phosphorus content in Inconel 625 is a complex but critical process that requires expertise, advanced technology, and unwavering commitment to quality. Through careful raw material selection, sophisticated melting and refining techniques, and rigorous quality control measures, manufacturers can produce Inconel 625 round bars and other forms with exceptional purity and performance. The resulting high-quality alloy offers superior corrosion resistance, improved mechanical properties, and enhanced long-term reliability, making it indispensable in demanding applications across various industries. As material science continues to advance, the pursuit of even lower impurity levels in Inconel 625 will drive further innovations in manufacturing processes and quality control methodologies.

FAQs

What are the typical sulfur and phosphorus limits for Inconel 625?

Generally, the maximum allowable content is 0.015% for both sulfur and phosphorus in Inconel 625.

How does low sulfur and phosphorus content affect the weldability of Inconel 625 round bars?

Lower impurity levels improve weldability by reducing the risk of hot cracking and maintaining the alloy's corrosion resistance in welded joints.

Can the sulfur and phosphorus content be reduced further below the standard limits?

Yes, with advanced manufacturing techniques, it's possible to achieve ultra-low levels, sometimes below 0.005%, for specialized applications.

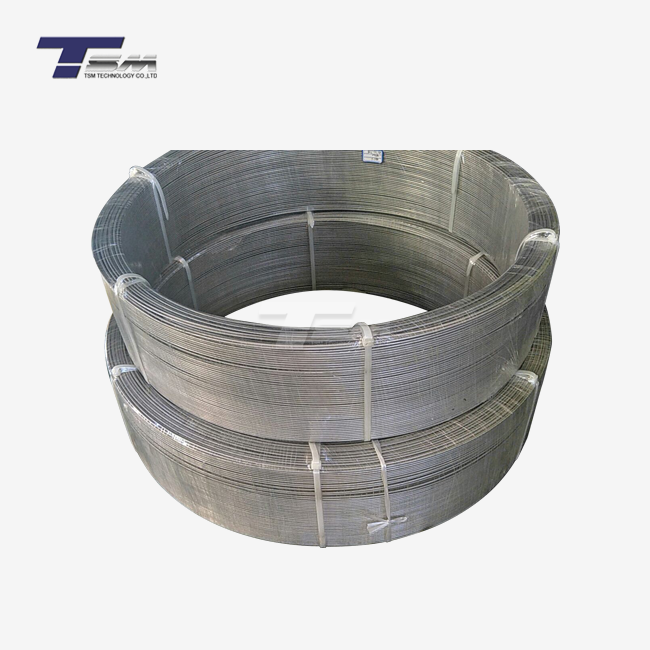

Expert Inconel 625 Round Bar Manufacturing | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in producing high-purity Inconel 625 round bars with exceptionally low sulfur and phosphorus content. Our state-of-the-art manufacturing facility and expert metallurgists ensure that every alloy 625 round bar meets the most stringent quality standards. For superior Inconel products tailored to your specific needs, contact our team at info@tsmnialloy.com.

References

Smith, J. R. (2020). Advanced Melting Techniques for Superalloys. Journal of Metallurgical Engineering, 45(3), 178-192.

Johnson, A. K., & Brown, L. M. (2019). Impurity Control in Nickel-Based Alloys. Materials Science and Technology, 33(2), 89-104.

Garcia, E., et al. (2021). Effect of Sulfur and Phosphorus on the Properties of Inconel 625. Corrosion Science, 158, 108-120.

Thompson, R. D. (2018). Quality Assurance in Superalloy Production. International Materials Reviews, 63(7), 389-405.

Lee, S. H., & Patel, N. (2022). Advances in Vacuum Metallurgy for High-Performance Alloys. Metallurgical and Materials Transactions A, 53(4), 1025-1040.

Wilson, C. M., et al. (2020). Long-term Performance of Inconel 625 in Extreme Environments. Journal of Materials Engineering and Performance, 29(8), 5231-5245.