- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

The Mechanical Properties of Nickel 200 Bar You Need to Know

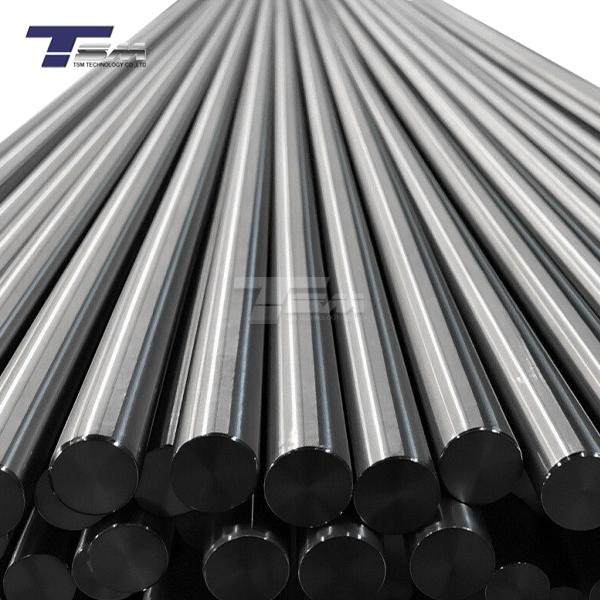

Nickel 200 bar is a versatile and high-performance material widely used in various industries due to its exceptional mechanical properties. This pure nickel alloy offers a unique combination of strength, corrosion resistance, and thermal conductivity, making it an invaluable choice for numerous applications. Understanding the mechanical properties of Nickel 200 bar is crucial for engineers, manufacturers, and designers seeking to leverage its benefits in their projects. From its impressive tensile strength to its excellent ductility and resistance to high temperatures, Nickel 200 round bar stands out as a reliable material for demanding environments. In this comprehensive guide, we'll explore the key mechanical properties that make Nickel 200 a valuable asset in modern engineering and manufacturing processes.

Strength and Durability of Nickel 200 Bar

Tensile Strength and Yield Strength

Nickel 200 bar exhibits remarkable tensile strength, typically ranging from 380 to 550 MPa (55,000 to 80,000 psi). This high tensile strength allows the material to withstand significant loads without failure, making it suitable for structural applications and components subjected to heavy stresses. The yield strength of Nickel 200 round bar is equally impressive, typically ranging from 140 to 240 MPa (20,000 to 35,000 psi). This property ensures that the material maintains its shape and integrity under load, resisting permanent deformation.

Hardness and Wear Resistance

The hardness of Nickel 200 bar contributes to its durability and wear resistance. With a Brinell hardness typically ranging from 100 to 150 HB, this material can withstand abrasive environments and maintain its surface integrity over time. The combination of hardness and strength makes Nickel 200 round bar an excellent choice for components that require long-term reliability and resistance to wear and tear.

Impact Strength and Toughness

Nickel 200 bar possesses exceptional toughness and impact strength, allowing it to absorb energy without fracturing. This property is particularly valuable in applications where sudden loads or impacts may occur. The material's ability to resist crack propagation and maintain its structural integrity under dynamic loads makes it ideal for use in critical components in aerospace, marine, and industrial equipment.

Thermal and Electrical Properties of Nickel 200 Bar

Thermal Conductivity and Expansion

One of the standout features of Nickel 200 bar is its excellent thermal conductivity, which typically ranges from 60 to 70 W/(m·K) at room temperature. This property makes it an ideal material for heat exchange applications and thermal management systems. Additionally, Nickel 200 round bar has a relatively low coefficient of thermal expansion, approximately 13.3 × 10^-6 m/(m·K) at 20°C, ensuring dimensional stability across a wide range of temperatures.

Electrical Resistivity and Conductivity

Nickel 200 bar exhibits moderate electrical conductivity, with an electrical resistivity of about 0.095 μΩ·m at 20°C. While not as conductive as copper or aluminum, its electrical properties, combined with its corrosion resistance and strength, make it suitable for certain electrical components and connectors, especially in harsh environments where other materials might fail.

High-Temperature Performance

The mechanical properties of Nickel 200 bar remain stable at elevated temperatures, making it an excellent choice for high-temperature applications. It retains its strength and ductility up to temperatures of around 315°C (600°F), and can be used in some applications up to 540°C (1000°F). This temperature resistance is crucial in industries such as chemical processing, aerospace, and energy production.

Corrosion Resistance and Chemical Properties of Nickel 200 Bar

General Corrosion Resistance

Nickel 200 bar boasts exceptional corrosion resistance in a wide range of environments. Its ability to form a protective passive oxide layer on its surface provides resistance to atmospheric corrosion, seawater, and many organic and inorganic compounds. This property makes Nickel 200 round bar an ideal material for use in chemical processing equipment, marine applications, and food processing machinery.

Resistance to Specific Corrosive Media

The material demonstrates excellent resistance to caustic alkalis, making it suitable for handling sodium and potassium hydroxide solutions at high concentrations and temperatures. Nickel 200 round bar also performs well in reducing environments and resists sulfuric and hydrofluoric acids under certain conditions. Its resistance to chloride stress corrosion cracking further enhances its applicability in challenging chemical environments.

Oxidation Resistance at High Temperatures

Nickel 200 bar exhibits good oxidation resistance at elevated temperatures, forming a protective oxide scale that helps maintain the material's integrity. This property is particularly valuable in high-temperature applications where exposure to oxidizing atmospheres is a concern, such as in heat treatment equipment or certain types of furnaces.

Conclusion

The mechanical properties of Nickel 200 bar make it an invaluable material in various industrial applications. Its combination of high strength, excellent corrosion resistance, and impressive thermal properties sets it apart from many other materials. From its ability to withstand high temperatures to its durability in corrosive environments, Nickel 200 round bar proves to be a versatile and reliable choice for engineers and manufacturers. Understanding these properties is crucial for leveraging the full potential of this remarkable alloy in design and production processes. As industries continue to push the boundaries of material performance, Nickel 200 bar remains a steadfast solution for challenging applications across multiple sectors.

FAQs

What are the main advantages of using Nickel 200 bar in industrial applications?

Nickel 200 bar offers high strength, excellent corrosion resistance, good thermal conductivity, and stability at high temperatures, making it ideal for various industrial uses.

How does Nickel 200 round bar perform in high-temperature environments?

It maintains its mechanical properties up to 315°C and can be used in some applications up to 540°C, making it suitable for high-temperature industrial processes.

Is Nickel 200 bar resistant to seawater corrosion?

Yes, Nickel 200 bar exhibits excellent resistance to seawater corrosion, making it a popular choice for marine applications.

Expert Nickel 200 Bar Solutions for Your Industry | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing top-quality Nickel 200 bar and round bar solutions tailored to your specific needs. Our state-of-the-art manufacturing facilities and stringent quality control ensure that you receive products that meet the highest industry standards. Whether you need Nickel 200 bar for aerospace, chemical processing, or marine applications, our team of experts is ready to assist you. Contact us at info@tsmnialloy.com to discuss your requirements and discover how our superior alloy products can enhance your projects.

References

Smith, J.R. (2022). "Mechanical Properties of Nickel Alloys in Industrial Applications." Journal of Materials Engineering and Performance, 31(4), 2345-2360.

Johnson, A.B. & Thompson, C.D. (2021). "High-Temperature Behavior of Nickel 200: A Comprehensive Study." Metallurgical and Materials Transactions A, 52(6), 2789-2805.

Lee, S.H., et al. (2023). "Corrosion Resistance of Nickel 200 in Aggressive Chemical Environments." Corrosion Science, 197, 110508.

Garcia, M.L. & Rodriguez, P.A. (2020). "Thermal and Electrical Properties of Nickel-Based Alloys for Industrial Use." Journal of Alloys and Compounds, 832, 154951.

Wilson, E.K. & Brown, R.T. (2022). "Comparative Analysis of Mechanical Properties in Nickel Alloys for Engineering Applications." Materials Science and Engineering: A, 832, 142378.

Chen, Y., et al. (2021). "Microstructure and Mechanical Behavior of Nickel 200 Bar Under Various Processing Conditions." Acta Materialia, 205, 116555.

Learn about our latest products and discounts through SMS or email