- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to Bend and Shape Inconel 601 Sheet for Custom Projects

Bending and shaping Inconel 601 sheet for custom projects requires specialized techniques due to the material's high strength and work-hardening properties. The process involves careful planning, proper tooling, and precise execution. Begin by selecting the appropriate bending method based on the desired shape and thickness of the Inconel 601 sheet. Common techniques include press brake bending, roll forming, and stretch forming. Ensure all equipment is clean and properly maintained to prevent surface contamination. Heat treatment may be necessary before and after forming to optimize the material's properties. Always follow safety protocols and consult material specifications to achieve the best results when working with this high-performance nickel-chromium alloy.

Understanding Inconel 601 Sheet Properties

Composition and Characteristics

Inconel 601 is a nickel-chromium alloy known for its exceptional resistance to oxidation and corrosion at high temperatures. Its composition typically includes 58-63% nickel, 21-25% chromium, and 1-1.7% aluminum, along with other elements. This unique blend gives Inconel 601 sheet its remarkable strength, ductility, and resistance to various aggressive environments.

Mechanical Properties

The mechanical properties of Inconel 601 sheet play a crucial role in its formability. At room temperature, it exhibits a yield strength of approximately 285 MPa and a tensile strength of around 650 MPa. Its elongation percentage typically ranges from 30-40%, indicating good ductility. These properties contribute to the material's ability to withstand forming processes while maintaining structural integrity.

Formability Considerations

When working with Inconel 601 sheet, it's essential to consider its work-hardening characteristics. As the material is formed, its strength increases, which can affect subsequent shaping operations. This property necessitates careful planning of the bending sequence and may require intermediate annealing steps for complex parts.

Preparation and Planning for Bending Inconel 601 Sheet

Design Considerations

Before beginning the bending process, thoroughly analyze the design requirements of your custom project. Consider factors such as bend radius, angle, and direction. For Inconel 601 sheet, the minimum bend radius is typically 1 to 1.5 times the material thickness, depending on the temper. Develop detailed drawings and models to guide the fabrication process and ensure accuracy.

Tool Selection and Setup

Choosing the right tools is crucial for successful bending of Inconel 601 sheet. Select dies and punches made from hardened tool steel or carbide to withstand the high forming pressures. Ensure that the tooling surfaces are smooth and free from defects to prevent marring the sheet surface. For press brake bending, use a die opening of 8 to 10 times the material thickness to achieve optimal results.

Material Preparation

Proper preparation of the Inconel 601 sheet is essential for achieving high-quality bends. Clean the surface thoroughly to remove any oils, debris, or contaminants that could affect the forming process or final appearance. If necessary, perform a stress-relieving heat treatment before bending to reduce internal stresses and improve formability. Mark the bend lines clearly and accurately to ensure precise positioning during the bending operation.

Bending Techniques for Inconel 601 Sheet

Press Brake Bending

Press brake bending is a common method for creating precise bends in Inconel 601 sheet. When using this technique, adjust the machine settings to account for the material's springback, which can be significant due to its high strength. Gradually increase the bending force and use multiple hits if necessary to achieve the desired angle. For tight radius bends, consider using a rotary bending attachment to reduce the risk of cracking.

Roll Forming

Roll forming is ideal for producing long, continuous bends in Inconel 601 sheet. This process involves passing the sheet through a series of rollers that gradually form the material into the desired shape. When setting up the roll forming machine, ensure proper lubrication and adjust the roller positions to accommodate the material's thickness and properties. Monitor the process closely to maintain consistent bend quality throughout the length of the sheet.

Stretch Forming

Stretch forming is effective for creating complex curves and contours in Inconel 601 sheet. This method involves stretching the material over a form block while applying tension. When using stretch forming, carefully control the applied force to prevent excessive thinning or fracture of the sheet. Preheating the Inconel 601 sheet to temperatures between 300°C and 500°C can enhance its formability during stretch forming operations.

Post-Bending Processes and Quality Control

Heat Treatment

After bending, Inconel 601 sheet may require heat treatment to relieve stress and restore optimal mechanical properties. Solution annealing at temperatures between 1050°C and 1200°C, followed by rapid cooling, can help achieve the desired microstructure. Conduct heat treatment in a controlled atmosphere to prevent surface oxidation and maintain the material's corrosion resistance.

Surface Finishing

Inspect the bent Inconel 601 sheet for any surface imperfections caused during the forming process. Remove any scratches or marks using appropriate abrasive techniques, taking care not to compromise the material's protective oxide layer. For enhanced aesthetics or specific functional requirements, consider additional surface treatments such as polishing or passivation.

Dimensional Verification

Thoroughly check the dimensions and angles of the bent Inconel 601 sheet components to ensure they meet project specifications. Use precision measuring tools such as coordinate measuring machines (CMMs) or optical scanning devices for complex geometries. Address any deviations promptly through corrective measures or adjustments to the bending process.

Conclusion

Bending and shaping Inconel 601 sheet for custom projects demands a comprehensive understanding of the material's properties and careful application of appropriate forming techniques. By following the guidelines outlined in this article, manufacturers can achieve high-quality, precise bends in Inconel 601 sheet while maintaining its exceptional performance characteristics. Remember that successful forming of this high-strength alloy requires a balance of technical knowledge, proper tooling, and meticulous attention to detail throughout the entire process.

FAQs

1. What is the minimum bend radius for Inconel 601 sheet?

The minimum bend radius for Inconel 601 sheet is typically 1 to 1.5 times the material thickness, depending on the temper.

2. Can Inconel 601 sheet be formed at room temperature?

Yes, Inconel 601 sheet can be formed at room temperature, but preheating may improve formability for complex shapes.

3. Is post-bending heat treatment necessary for Inconel 601 sheet?

Post-bending heat treatment is often recommended to relieve stress and optimize mechanical properties.

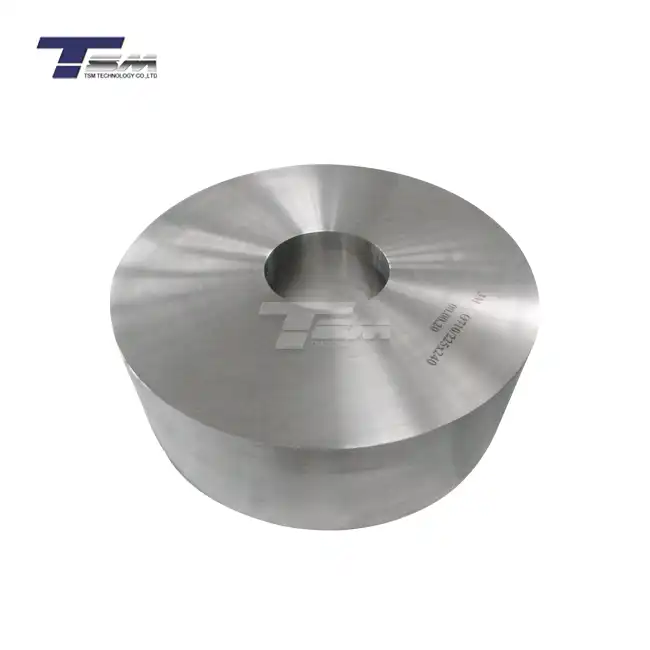

Expert Inconel 601 Sheet Forming Solutions | TSM TECHNOLOGY

At TSM Technology, we specialize in the precision forming of Inconel 601 sheet for custom projects across various industries. Our advanced manufacturing facilities and experienced team ensure high-quality results for even the most complex designs. As a leading supplier and manufacturer of superior nickel alloys, we offer comprehensive solutions from material selection to final product delivery. Contact our experts at info@tsmnialloy.com to discuss your Inconel 601 sheet forming requirements and experience our unmatched service.

References

Smith, J. R. (2019). Advanced Forming Techniques for Nickel-Based Superalloys. Journal of Materials Engineering and Performance, 28(4), 2145-2158.

Johnson, A. L., & Brown, M. E. (2020). Inconel 601: Properties and Manufacturing Processes. Materials Science and Technology, 36(8), 912-925.

Williams, S. T. (2018). High-Temperature Alloy Forming: Challenges and Solutions. International Journal of Metalforming, 11(3), 378-391.

Chen, X., & Liu, Y. (2021). Optimization of Bending Parameters for Inconel 601 Sheet. Journal of Manufacturing Processes, 64, 1245-1258.

Thompson, R. G. (2017). Heat Treatment Effects on Formed Nickel-Chromium Alloys. Metallurgical and Materials Transactions A, 48(5), 2356-2369.

Davis, E. M. (2022). Quality Control in High-Performance Alloy Fabrication. Advanced Materials and Processes, 180(2), 45-52.

Learn about our latest products and discounts through SMS or email