Understanding Monel 400 Tubing: Properties and Applications

Composition and Unique Characteristics of Monel 400

Monel 400 is a nickel-copper alloy renowned for its exceptional properties. Composed of approximately 67% nickel and 23% copper, this material offers superior resistance to corrosion in various environments. Its unique composition provides excellent strength and durability, making it ideal for applications in harsh conditions.

The alloy's resistance to seawater, steam at high temperatures, and many acids and alkalis sets it apart from other materials. Monel 400 maintains its mechanical properties across a wide temperature range, from cryogenic conditions to temperatures as high as 480°C. This versatility makes it a go-to choice for industries requiring materials that can withstand extreme conditions.

Key Industries Utilizing Monel 400 Tubing

Monel 400 tubing finds extensive use across several critical industries:

- Aerospace and Defense: Used in fuel lines, hydraulic systems, and cryogenic components

- Chemical Processing: Ideal for handling corrosive substances, including sulfuric acid

- Marine Engineering: Employed in seawater-handling equipment and offshore platforms

- Oil and Gas: Used in wellhead components and offshore drilling equipment

- Power Generation: Applied in steam turbine blading and condenser tubing

In each of these industries, Monel 400 tubing plays a crucial role in ensuring system integrity and longevity, particularly in corrosive or high-stress environments.

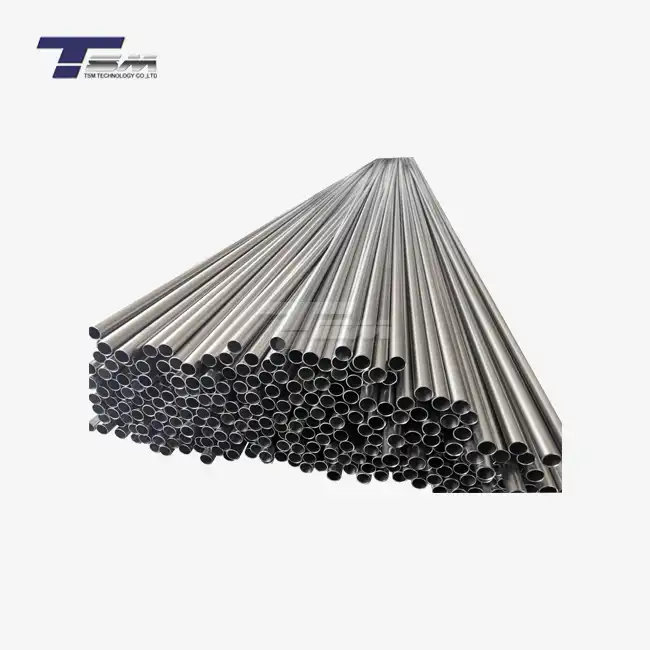

Standards and Specifications for Monel 400 Tubing

Monel 400 tubing is manufactured to meet rigorous industry standards, ensuring consistent quality and performance. Key specifications include:

- ASTM B163: Standard Specification for Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes

- ASME SB163: Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes

- EN 10095: Heat Resisting Steels and Nickel Alloys

These standards govern the chemical composition, mechanical properties, and dimensional tolerances of Monel 400 tubing. Adherence to these specifications ensures that the tubing meets the demanding requirements of various industrial applications.

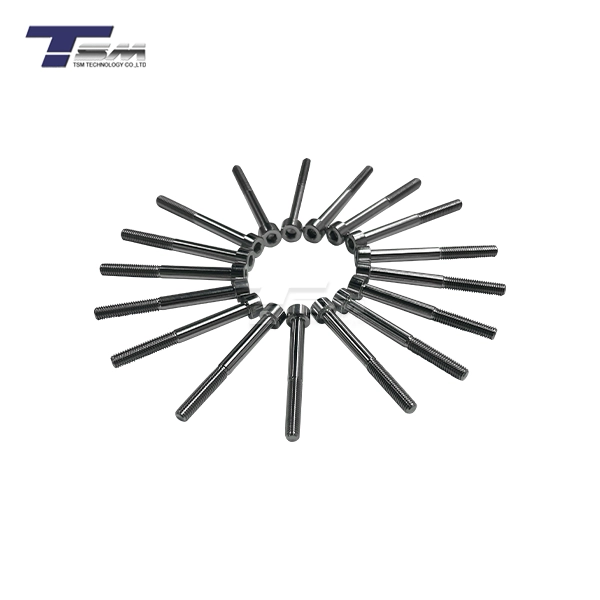

Seamless Monel 400 Tubes: Advantages and Ideal Applications

Manufacturing Process of Seamless Monel 400 Tubes

Seamless Monel 400 tubes are produced through a sophisticated manufacturing process that ensures uniformity and strength throughout the tube's structure. The process begins with a solid cylindrical billet of Monel 400 alloy, which is heated to a high temperature to increase its malleability. This heated billet is then pierced and rolled over a mandrel to create a hollow tube.

The tube undergoes several passes through precision rollers, gradually reducing its diameter and wall thickness to the desired specifications. This process, known as cold drawing, enhances the mechanical properties of the tube, improving its strength and surface finish. The result is a seamless tube with consistent properties throughout its entire length.

Benefits of Seamless Monel 400 Tubes

Seamless Monel 400 tubes offer several distinct advantages:

- Superior Strength: The uniform structure provides enhanced resistance to high pressures and stresses.

- Excellent Corrosion Resistance: The absence of welds eliminates potential weak points for corrosive attack.

- Consistent Wall Thickness: Ensures uniform heat transfer and flow characteristics.

- Higher Reliability: Ideal for critical applications where failure is not an option.

- Better Fatigue Resistance: The homogeneous structure resists cyclic stresses more effectively.

These benefits make seamless Monel 400 tubing the preferred choice for applications demanding the highest levels of performance and reliability.

Optimal Applications for Seamless Monel 400 Tubes

Seamless Monel 400 tubes are particularly well-suited for:

- High-Pressure Systems: In oil and gas exploration, where tubes must withstand extreme pressures.

- Aerospace Components: For fuel lines and hydraulic systems in aircraft, where safety is paramount.

- Chemical Reactors: In processes involving corrosive chemicals at high temperatures and pressures.

- Heat Exchangers: In critical cooling systems where consistent heat transfer is essential.

- Cryogenic Applications: Where materials must maintain strength and ductility at extremely low temperatures.

In these applications, the superior properties of seamless Monel 400 tubes provide the necessary performance and safety margins required by industry standards and regulations.

Welded Monel 400 Tubes: Cost-Effective Solutions for Specific Needs

Production Techniques for Welded Monel 400 Tubes

Welded Monel 400 tubes are manufactured using a different process compared to their seamless counterparts. The production begins with flat Monel 400 strips or plates, which are formed into a cylindrical shape. The edges are then welded together using advanced welding techniques such as TIG (Tungsten Inert Gas) or laser welding.

After welding, the tubes undergo various quality control processes, including non-destructive testing methods like ultrasonic or X-ray inspection, to ensure the integrity of the weld seam. The tubes may also be subjected to heat treatment to relieve stress and homogenize the microstructure around the weld area.

Advantages of Welded Monel 400 Tubes

Welded Monel 400 tubing offers several benefits:

- Cost-Effectiveness: Generally less expensive to produce than seamless tubes, especially in larger diameters.

- Availability: Can be manufactured in a wider range of sizes and lengths.

- Flexibility in Production: Easier to customize for specific dimensions or small batch orders.

- Suitable for Many Applications: Performs well in moderate pressure and temperature conditions.

- Consistent Wall Thickness: Offers good control over wall thickness across the tube length.

These advantages make welded Monel 400 tubes an attractive option for many industrial applications where extreme pressure resistance is not the primary concern.

Best-Suited Applications for Welded Monel 400 Tubes

Welded Monel 400 tubes are ideal for:

- General Purpose Piping: In chemical processing plants and refineries for fluid transport.

- Heat Exchangers: In less critical or lower-pressure applications.

- Architectural Applications: Where corrosion resistance is needed but high pressure is not a factor.

- Marine Equipment: For seawater handling systems in less demanding conditions.

- Food Processing: Where sanitary conditions are important, and pressures are moderate.

In these applications, welded Monel 400 tubes provide a balance of performance and cost-effectiveness, meeting industry standards while offering economic advantages for large-scale implementations.

Conclusion

Choosing between seamless and welded Monel 400 tubing requires careful consideration of your specific application requirements. Seamless tubes offer superior strength and reliability, making them ideal for high-pressure, safety-critical applications in aerospace, chemical processing, and oil & gas industries. Welded tubes provide a cost-effective solution for less demanding environments, suitable for general piping, heat exchangers, and marine applications where moderate pressures are involved. Both types meet rigorous industry standards, ensuring quality and performance. Consider factors such as operating pressure, temperature, corrosion resistance, and budget when making your selection. For optimal results, consult with experts to match the tube type to your specific industry needs and environmental conditions.

FAQs

What is the maximum temperature Monel 400 tubing can withstand?

Monel 400 tubing can operate efficiently at temperatures up to 480°C, making it suitable for high-temperature applications.

Are there any special surface treatments available for Monel 400 tubing?

Yes, TSM Technology offers sandblasting and anodizing surface treatments for Monel 400 tubing to enhance its properties for specific applications.

What certifications does TSM Technology's Monel 400 tubing have?

Our Monel 400 tubing is certified to AS9100D, ISO 9001, and EN 10204 3.1 standards, ensuring top quality and reliability.

Can TSM Technology provide custom sizes for Monel 400 tubing?

Absolutely. We offer customization options with outer diameters ranging from 6.0 to 114 mm and wall thicknesses from 0.5 to 15 mm.

What industries commonly use Monel 400 tubing?

Monel 400 tubing is widely used in aerospace, chemical processing, marine engineering, and oil & gas industries due to its exceptional corrosion resistance and mechanical properties.

Choose TSM Technology for Your Monel 400 Tubing Needs

TSM Technology stands as a premier manufacturer and supplier of superior Monel 400 tubing. With our state-of-the-art facilities, including 3 factories, 8 production lines, and over 100 machines, we ensure unparalleled quality and precision in every product. Our Monel 400 tubing, compliant with ASTM B163, ASME SB163, and EN 10095 standards, is available in a wide range of dimensions to meet diverse industrial needs. Trust in our expertise, rigorous quality control, and commitment to innovation for all your Monel 400 tubing requirements. For more information or to request a free sample, contact us at info@tsmnialloy.com.

References

ASTM International. (2020). "ASTM B163 - Standard Specification for Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes."

American Society of Mechanical Engineers. (2019). "ASME SB163 - Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes."

European Committee for Standardization. (2018). "EN 10095 - Heat Resisting Steels and Nickel Alloys."

Special Metals Corporation. (2021). "Monel alloy 400 - Technical Datasheet."

Tubacex Group. (2022). "Seamless vs Welded Tubes: A Comparative Analysis for Industrial Applications."

Journal of Materials Engineering and Performance. (2023). "Performance Evaluation of Monel 400 Tubing in Corrosive Environments: Seamless vs Welded Structures."