Understanding Alloy 400 Pipe Certifications

Material Test Reports (MTRs)

Material Test Reports (MTRs) are crucial documents that provide detailed information about the chemical composition, mechanical properties, and testing results of Alloy 400 pipes. These reports typically include:

- Chemical analysis results confirming the correct nickel-copper alloy composition

- Tensile strength, yield strength, and elongation measurements

- Heat treatment details, if applicable

- Specific batch or lot numbers for traceability

MTRs are essential for ensuring that the Alloy 400 pipe meets the required specifications and performs as expected in demanding environments.

ASTM and ASME Standards Compliance

Adherence to industry standards is paramount for Alloy 400 pipe certifications. The two primary standards are:

- ASTM B165: Standard Specification for Nickel-Copper Alloy (UNS N04400) Seamless Pipe and Tube

- ASME SB165: Specification for Nickel-Copper Alloy (UNS N04400) Seamless Pipe and Tube

These standards outline the requirements for chemical composition, mechanical properties, dimensions, and testing procedures. Certification to these standards ensures that the Alloy 400 pipe meets internationally recognized quality benchmarks.

Quality Management System Certifications

Manufacturers of Alloy 400 pipe should possess quality management system certifications, such as:

- ISO 9001: Demonstrates a commitment to consistent quality and customer satisfaction

- AS9100: Specific to aerospace industry requirements

- API Q1: Relevant for oil and gas applications

These certifications validate that the manufacturer has robust quality control processes in place throughout production.

Industry-Specific Certifications for Alloy 400 Pipe

Marine and Offshore Certifications

For marine applications, Alloy 400 pipe may require additional certifications:

- ABS (American Bureau of Shipping) Type Approval: Confirms that the material meets the structural and safety standards for marine construction and ship systems.

- DNV GL (Det Norske Veritas Germanischer Lloyd) Certification: Verifies corrosion resistance, fatigue strength, and long-term performance in seawater environments.

- Lloyd's Register Approval: Ensures compliance with global maritime regulations and reliability under high-pressure, high-salinity conditions.

These certifications collectively guarantee that Alloy 400 pipe maintains integrity and stability in offshore and marine operations.

Oil and Gas Industry Certifications

The oil and gas sector often requires specific certifications for Alloy 400 pipe:

- NACE MR0175/ISO 15156: Certifies resistance to sulfide stress cracking in sour gas and other corrosive service conditions.

- API 5L: Establishes quality and dimensional standards for line pipe used in the transportation of oil, gas, and water.

- NORSOK M-650: Qualifies manufacturers for producing special materials used in demanding offshore environments.

These certifications ensure Alloy 400 pipe can withstand extreme temperatures, high pressures, and aggressive chemical exposure during extraction and processing.

Aerospace and Defense Certifications

For aerospace applications, Alloy 400 pipe may need to meet additional requirements:

- AS9100: Defines quality management standards specific to aviation, space, and defense manufacturing.

- NADCAP (National Aerospace and Defense Contractors Accreditation Program): Validates process consistency and high-precision metallurgical control.

- OEM (Original Equipment Manufacturer) Approvals: Confirm compliance with proprietary specifications for performance-critical components.

These certifications ensure Alloy 400 pipe delivers exceptional reliability, strength, and corrosion resistance required in aerospace and defense systems.

Ensuring Authenticity and Traceability of Certifications

Third-Party Verification

To guarantee the authenticity of certifications for Alloy 400 pipe, third-party verification is often employed:

- Independent laboratories conduct chemical composition, tensile strength, and corrosion resistance tests to confirm compliance with required standards.

- Certification bodies perform audits to evaluate manufacturing procedures, documentation accuracy, and process integrity.

- Witness testing by client representatives or accredited inspectors ensures transparency during production and testing stages.

These measures provide additional assurance that every Alloy 400 pipe meets all technical and regulatory specifications.

Digital Certification Systems

Modern certification processes for Alloy 400 pipe increasingly utilize digital systems:

- Blockchain-based Material Test Reports create immutable digital records, preventing unauthorized modification.

- QR codes printed on certificates allow users to instantly verify authenticity through online platforms.

- Centralized digital databases enable real-time access to certification history and validity status.

These innovations enhance traceability, promote transparency, and significantly reduce the risk of fraudulent certifications across global supply chains.

Retention and Accessibility of Certification Records

Proper management of certification records is crucial:

- Companies maintain both digital and hard-copy archives to ensure data preservation and long-term traceability.

- Secure access systems, such as password-protected databases, allow only authorized personnel to retrieve records.

- Regular internal and external audits verify record completeness, consistency, and compliance with regulatory standards.

Efficient record retention practices safeguard certification integrity and ensure accessibility throughout the Alloy 400 pipe's service life.

Conclusion

The certifications required for Alloy 400 pipe are comprehensive and tailored to ensure the highest standards of quality and performance across various industries. From basic material test reports to industry-specific approvals, these certifications provide assurance of the pipe's suitability for critical applications. As technology advances, digital certification methods are enhancing traceability and verification processes. For businesses seeking Alloy 400 pipe, partnering with reputable manufacturers who can provide all necessary certifications is crucial to ensure compliance, reliability, and safety in demanding operational environments.

FAQs

How often should Alloy 400 pipe certifications be renewed?

Most certifications require annual or biennial renewals, but specific timeframes can vary. ISO 9001, for example, is typically renewed every three years with annual surveillance audits.

Can I use Alloy 400 pipe with outdated certifications?

It's not recommended. Using pipe with expired certifications may violate regulations and compromise safety. Always ensure certifications are current before use.

Are digital certifications as valid as paper ones?

Yes, digital certifications from reputable sources are equally valid and often preferred due to easier verification and improved traceability.

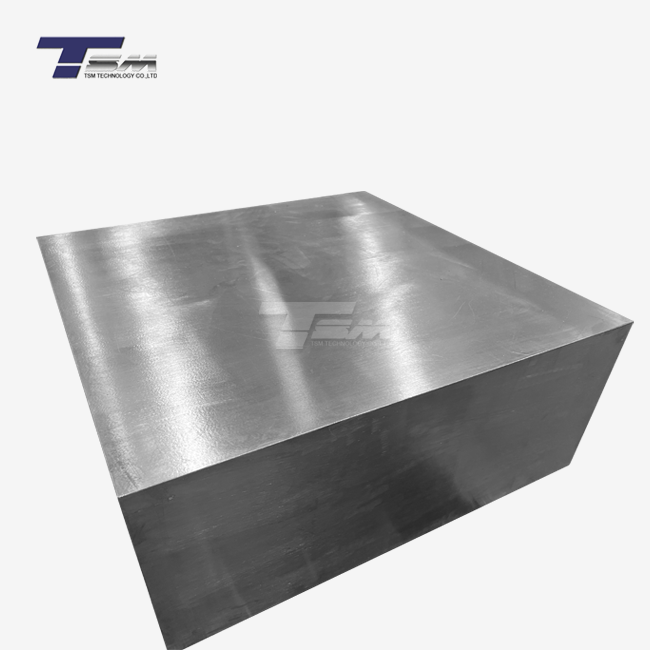

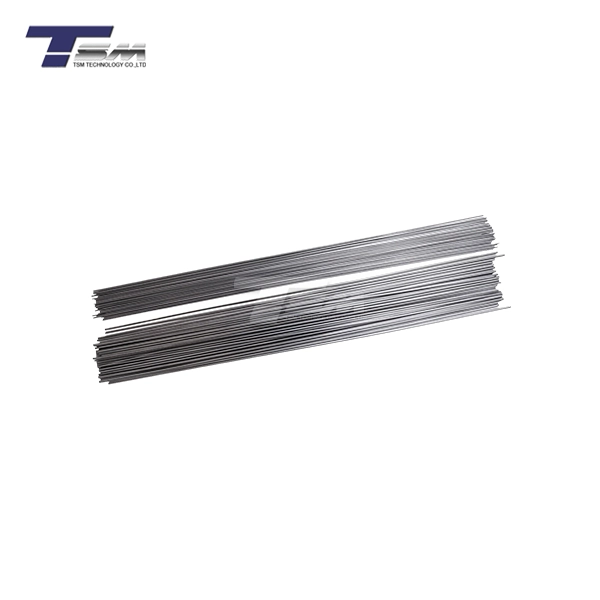

Expert Alloy 400 Pipe Solutions | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in high-quality Alloy 400 pipe manufacturing. With our state-of-the-art facilities, including 3 factories, 8 production lines, and over 100 machines, we ensure precision and consistency in every product. Our Monel 400 (UNS N04400) pipes meet ASTM B165, ASME SB165, and EN 10095 standards, available in various sizes and with customization options. We provide comprehensive material certifications and free samples. For superior Alloy 400 pipe solutions, contact us at info@tsmnialloy.com.

References

ASTM International. (2020). "ASTM B165 - Standard Specification for Nickel-Copper Alloy (UNS N04400) Seamless Pipe and Tube."

American Society of Mechanical Engineers. (2019). "ASME Boiler and Pressure Vessel Code, Section II: Materials."

International Organization for Standardization. (2015). "ISO 9001:2015 Quality management systems — Requirements."

NACE International. (2015). "NACE MR0175/ISO 15156 - Materials for use in H2S-containing Environments in Oil and Gas Production."

SAE International. (2016). "AS9100 Rev D - Quality Management Systems - Requirements for Aviation, Space and Defense Organizations."

American Petroleum Institute. (2018). "API Specification 5L: Specification for Line Pipe."