Understanding Monel 400 Tubing and Its High-Pressure Applications

Composition and Properties of Monel 400

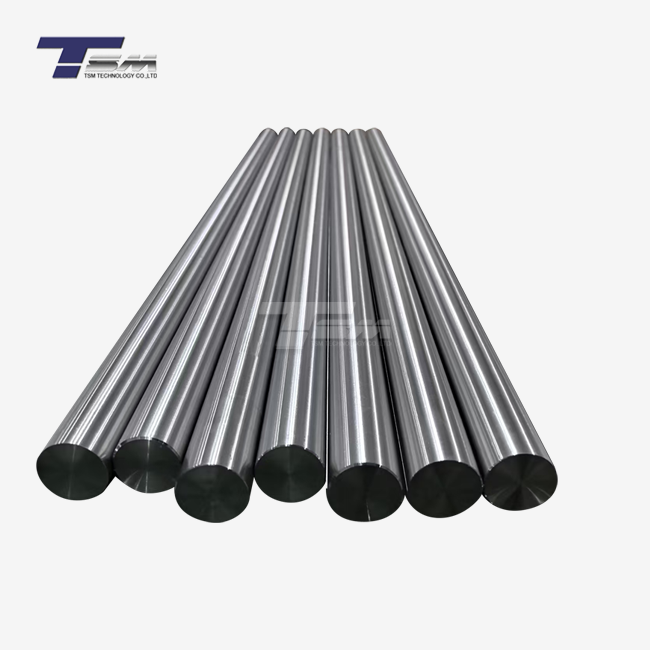

Monel 400 is a nickel-copper alloy renowned for its exceptional strength and corrosion resistance. Composed of approximately 67% nickel and 23% copper, this alloy exhibits remarkable durability in harsh environments. Its unique composition grants it superior resistance to acids, alkalis, and seawater, making it an ideal choice for high-pressure systems in various industries.

Common High-Pressure Applications

Monel 400 tubing finds extensive use in high-pressure applications across multiple sectors. In the aerospace industry, it's utilized in fuel lines and hydraulic systems where reliability is crucial. Chemical processing plants rely on Monel 400 for handling corrosive substances under high pressure. Marine engineering applications include subsea manifolds and offshore platforms, where the tubing must withstand extreme pressures and corrosive seawater.

Importance of Pressure Testing

Pressure testing is a critical step in ensuring the integrity and safety of Monel 400 tubing in high-pressure systems. It verifies the tubing's ability to withstand operational pressures, identifies potential weak points or manufacturing defects, and ensures compliance with industry standards. Regular pressure testing also helps prevent catastrophic failures, protecting both equipment and personnel in demanding industrial environments.

Preparation and Safety Measures for Pressure Testing Monel 400 Tubing

Equipment and Tools Required

To conduct a proper pressure test on Monel 400 tubing, you'll need specialized equipment. This includes a high-pressure pump capable of reaching at least 1.5 times the tubing's working pressure, pressure gauges with appropriate range and accuracy, fittings and adapters compatible with Monel 400, and a pressure relief valve for safety. Additionally, ensure you have proper personal protective equipment (PPE) such as safety glasses, gloves, and protective clothing.

Safety Protocols and Precautions

Safety is paramount when pressure testing Monel 400 tubing. Establish a clear safety perimeter around the testing area and restrict access to authorized personnel only. Always wear appropriate PPE throughout the testing process. Familiarize yourself with emergency shutdown procedures and ensure all team members are briefed on safety protocols. Never exceed the maximum test pressure specified for the tubing, and always increase pressure gradually to avoid sudden stress on the system.

Pre-Test Inspection and Setup

Before initiating the pressure test, conduct a thorough visual inspection of the Monel 400 tubing. Look for any signs of damage, deformation, or corrosion that could compromise the test's integrity. Ensure all connections are properly tightened and sealed. Set up the testing apparatus according to the manufacturer's guidelines, double-checking that all components are rated for the intended test pressure. Calibrate pressure gauges and verify the accuracy of all measuring instruments to ensure reliable test results.

Step-by-Step Guide to Pressure Testing Monel 400 Tubing

| Stage | Procedure | Key Requirements |

|---|---|---|

| 1. Initial Pressurization & Leak Check |

|

|

| 2. Gradual Pressure Increase & Monitoring |

|

|

| 3. Holding Test Pressure & Final Inspection |

|

|

Interpreting Results and Post-Test Procedures

Analyzing Pressure Test Data

After completing the pressure test on Monel 400 tubing, it's crucial to analyze the collected data thoroughly. Review pressure readings throughout the test duration, looking for any inconsistencies or unexpected pressure drops. Compare the results against the acceptance criteria specified in relevant standards such as ASTM B163 or ASME SB163. Pay special attention to any pressure fluctuations that occurred during the hold period, as these can indicate potential issues with the tubing's integrity.

Documentation and Reporting

Proper documentation is essential for maintaining a record of the pressure test and ensuring traceability. Create a comprehensive report that includes all test parameters, such as maximum pressure reached, duration of the test, and any observations made during the process. Include details of the Monel 400 tubing being tested, such as dimensions, batch number, and material certification. Attach any relevant photos or diagrams that illustrate the test setup or any notable findings. This documentation is crucial for quality assurance and may be required for regulatory compliance.

Post-Test Cleaning and Preparation for Use

Once the pressure test is complete and the results are satisfactory, it's important to properly prepare the Monel 400 tubing for its intended use. Thoroughly clean the tubing to remove any residual test media or contaminants. If the tubing will be used in sensitive applications, such as in the aerospace or chemical processing industries, consider additional cleaning processes like ultrasonic cleaning or passivation to ensure optimal performance. Finally, protect the tubing ends with appropriate caps or covers to prevent contamination during storage or transportation.

Conclusion

Pressure testing Monel 400 tubing for high-pressure systems is a critical process that ensures the safety and reliability of industrial applications. By following a systematic approach, from thorough preparation to careful execution and detailed analysis, you can effectively verify the integrity of Monel 400 tubing. This process not only guarantees compliance with industry standards but also provides peace of mind in demanding environments where failure is not an option. Remember, the key to successful pressure testing lies in attention to detail, adherence to safety protocols, and proper documentation of results.

FAQs

Q: What makes Monel 400 tubing suitable for high-pressure systems?

A: Monel 400 tubing is ideal for high-pressure systems due to its excellent strength, corrosion resistance, and ability to withstand extreme temperatures up to 480°C. Its nickel-copper alloy composition provides superior resistance to pitting and chloride stress corrosion, making it perfect for harsh environments in aerospace, chemical processing, and marine applications.

Q: How often should pressure testing be performed on Monel 400 tubing?

A: The frequency of pressure testing depends on the specific application and industry standards. However, it's generally recommended to conduct pressure tests during initial installation, after any repairs or modifications, and at regular intervals as part of preventive maintenance to ensure ongoing system integrity and safety.

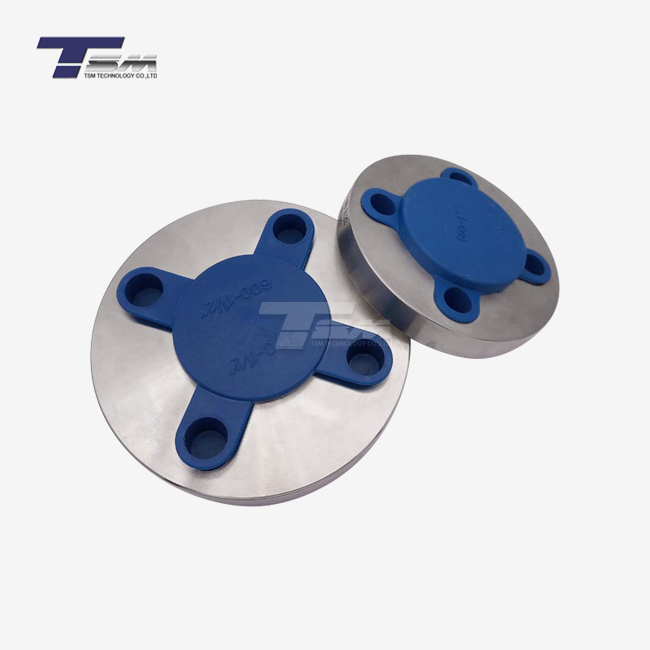

Experience the Superior Quality of TSM Technology's Monel 400 Tubing

At TSM Technology, we pride ourselves on delivering top-tier Monel 400 tubing that exceeds industry standards. With our state-of-the-art manufacturing facilities, rigorous quality control processes, and commitment to innovation, we ensure that every piece of Monel 400 tubing meets the most demanding requirements. Our products are trusted by leading companies in aerospace, chemical processing, and marine engineering worldwide. Experience the difference of TSM Technology's Monel 400 tubing in your high-pressure systems. For more information or to request a sample, contact us at info@tsmnialloy.com.

References

ASTM International. (2020). "ASTM B163 - Standard Specification for Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes"

American Society of Mechanical Engineers. (2019). "ASME SB163 - Specification for Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes"

Nickel Institute. (2018). "Nickel-Copper Alloys: Properties and Applications of Monel 400"

Journal of Materials Engineering and Performance. (2021). "Pressure Testing Methodologies for High-Performance Alloy Tubing in Extreme Environments"

International Association of Classification Societies. (2019). "Requirements Concerning Materials and Welding for Marine Applications"

Aerospace Materials Handbook. (2022). "Chapter 7: Nickel Alloys in Aerospace Applications - Testing and Certification"