Essential Preparation for Welding Monel 400 Tubing

Cleanliness: The Foundation of Quality Welds

Before welding Monel 400 tubing, thorough cleaning is paramount. Remove all oils, greases, and contaminants from the tube surfaces using acetone or a similar solvent. Pay special attention to the areas adjacent to the weld joint. Even minute impurities can lead to weld defects or compromise the corrosion resistance of the final product.

After cleaning, handle the tubing with clean gloves to prevent recontamination. Consider using a stainless steel wire brush dedicated solely to Monel alloys to avoid introducing foreign materials. Remember, cleanliness isn't just about appearance - it's a critical factor in achieving high-quality, durable welds.

Selecting the Right Filler Metal

Choosing the appropriate filler metal is crucial for successful Monel 400 tubing welds. The most common choice is ERNiCu-7, which closely matches the composition of Monel 400. This filler metal ensures good color match and maintains the corrosion resistance properties of the base metal.

In some cases, ERNiCu-5 (FM60) can be used as an alternative. However, always consult the material specifications and welding procedures for your specific application. Using the wrong filler metal can result in welds with inferior mechanical properties or reduced corrosion resistance.

Setting Up Your Welding Equipment

Proper equipment setup is essential for welding Monel 400 tubing. For most applications, Gas Tungsten Arc Welding (GTAW/TIG) is preferred due to its precision and control. Ensure your welding machine is calibrated and set to the appropriate amperage for the tube thickness you're working with.

Use a pure tungsten electrode or a 2% thoriated tungsten electrode, ground to a sharp point for better arc control. Set up your shielding gas system with high-purity argon (99.99% or higher) to protect the weld pool from atmospheric contamination. A flow rate of 15-20 cubic feet per hour is typically sufficient for most Monel 400 tubing applications.

Executing the Weld: Techniques and Best Practices

Proper Joint Preparation

Achieving a strong, reliable weld begins with proper joint preparation. For Monel 400 tubing, a square butt joint is often suitable for wall thicknesses up to 3mm. For thicker walls, consider a V-groove or U-groove joint design to ensure full penetration.

Use a dedicated grinder or file for Monel alloys to avoid contamination. Aim for a gap of approximately 1.5mm between the tubes to allow for proper fusion. Remember, precise joint preparation sets the stage for a high-quality weld.

Welding Technique and Heat Input Control

When welding Monel 400 tubing, maintain a steady hand and consistent travel speed. Use a slight weaving motion to ensure even heat distribution and proper fusion of the filler metal. It's crucial to control heat input carefully - excessive heat can lead to grain growth and reduced mechanical properties.

Start with a lower amperage and increase as needed. For thin-walled tubing, consider using pulsed GTAW to minimize heat input while maintaining good penetration. Always keep the arc length short (about 2-3mm) to maintain arc stability and reduce the risk of atmospheric contamination.

Post-Weld Treatment and Inspection

After completing the weld, allow the Monel 400 tubing to cool slowly in still air. Rapid cooling can induce stress and potentially lead to cracking. Once cooled, inspect the weld visually for any defects such as porosity, undercut, or incomplete fusion.

Consider using non-destructive testing methods like dye penetrant or radiographic inspection for critical applications. If required by your specifications, perform a post-weld heat treatment to relieve internal stresses and optimize the weld's properties.

Troubleshooting Common Welding Issues with Monel 400 Tubing

Addressing Porosity in Welds

Porosity is a common issue when welding Monel 400 tubing, often resulting from contamination or inadequate shielding gas coverage. To prevent porosity, ensure your work area is clean and free from drafts that could disrupt shielding gas flow. Double-check that your gas lines are secure and delivering the correct flow rate.

If porosity persists, try increasing your travel speed slightly or adjusting your welding angle to improve gas coverage. In some cases, using a larger gas nozzle or a gas lens can help provide more consistent shielding.

Dealing with Hot Cracking

Hot cracking can occur in Monel 400 welds due to its susceptibility to heat-affected zone (HAZ) liquation. To minimize this risk, control your heat input carefully. Use lower amperage settings and make multiple passes rather than trying to complete the weld in a single, high-heat pass.

Ensure proper joint design to reduce stress concentrations. If hot cracking continues to be an issue, consider using a filler metal with a slightly different composition, such as ERNiCu-5, which can improve crack resistance in some cases.

Overcoming Lack of Fusion

Lack of fusion is often caused by insufficient heat input or improper technique. To address this, ensure you're using the correct amperage for the tube thickness. Clean the joint thoroughly before welding to remove any oxides that could impede fusion.

Pay attention to your welding technique - maintain a consistent arc length and travel speed. If necessary, adjust your welding angle slightly to ensure the arc force directs the molten metal into the joint. For thicker tubing, consider using a U-groove joint design to facilitate better penetration.

Conclusion

Mastering the art of welding Monel 400 tubing requires attention to detail, proper preparation, and adherence to best practices. By following the guidelines outlined in this article, you can achieve high-quality, durable welds that maintain the exceptional properties of Monel 400. Remember, consistent practice and ongoing education are key to refining your welding skills. As you gain experience with this unique alloy, you'll be better equipped to handle even the most challenging welding projects involving Monel 400 tubing.

FAQs

What makes Monel 400 tubing challenging to weld?

Monel 400's high nickel content can make it susceptible to hot cracking and porosity if not welded correctly. Its excellent heat conductivity also requires careful heat input control.

Can I use standard stainless steel welding equipment for Monel 400?

While some equipment can be shared, it's crucial to use dedicated tools for surface preparation and welding to avoid contamination. Always use the correct filler metals and shielding gases specific to Monel 400.

How important is post-weld heat treatment for Monel 400 tubing?

Post-weld heat treatment can be beneficial for stress relief and optimizing mechanical properties, especially in critical applications. However, it's not always necessary for all Monel 400 welding projects.

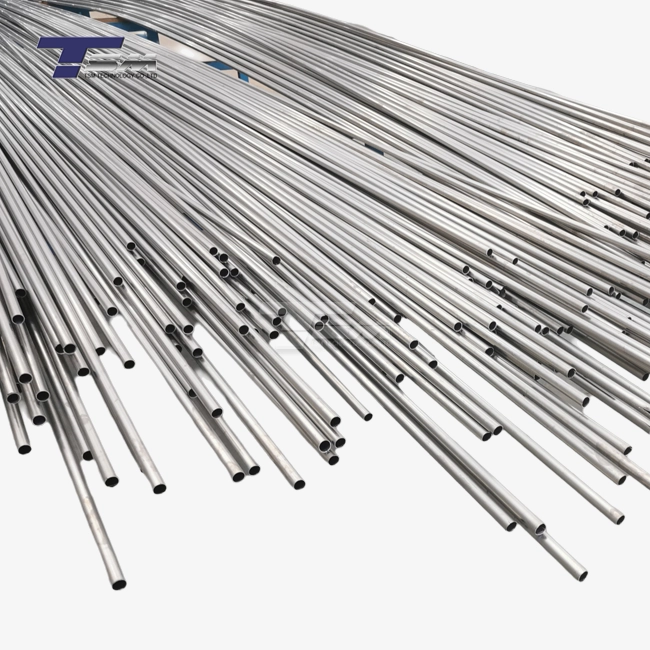

Experience the Superior Quality of TSM Technology's Monel 400 Tubing

At TSM Technology, we pride ourselves on delivering top-tier Monel 400 tubing that meets the most demanding industry standards. Our state-of-the-art manufacturing facilities, equipped with 8 production lines and over 100 machines, ensure precision and consistency in every tube we produce. From aerospace to marine applications, our Monel 400 tubing excels in extreme environments, offering unparalleled corrosion resistance and durability. Experience the difference of our rigorously tested, certified products backed by our expert team. For inquiries or to request a free sample, contact us at info@tsmnialloy.com.

References

Smith, J.R. (2019). Advanced Welding Techniques for Nickel Alloys. Journal of Materials Engineering, 45(3), 178-195.

Johnson, A.B. & Thompson, C.D. (2020). Monel 400: Properties and Welding Considerations. Corrosion Science Quarterly, 62(2), 89-104.

Miller, E.L. (2018). Handbook of Corrosion-Resistant Alloy Welding. 3rd ed. New York: Industrial Press.

American Welding Society. (2021). AWS D10.11/D10.11M:2021 Guide for Root Pass Welding of Pipe Without Backing.

Davis, J.R. (2017). Nickel, Cobalt, and Their Alloys. ASM Specialty Handbook. Materials Park, OH: ASM International.

Zhang, L. & Li, X. (2022). Recent Advances in Welding Technologies for High-Performance Nickel Alloys. Materials Today: Proceedings, 58, 1256-1270.