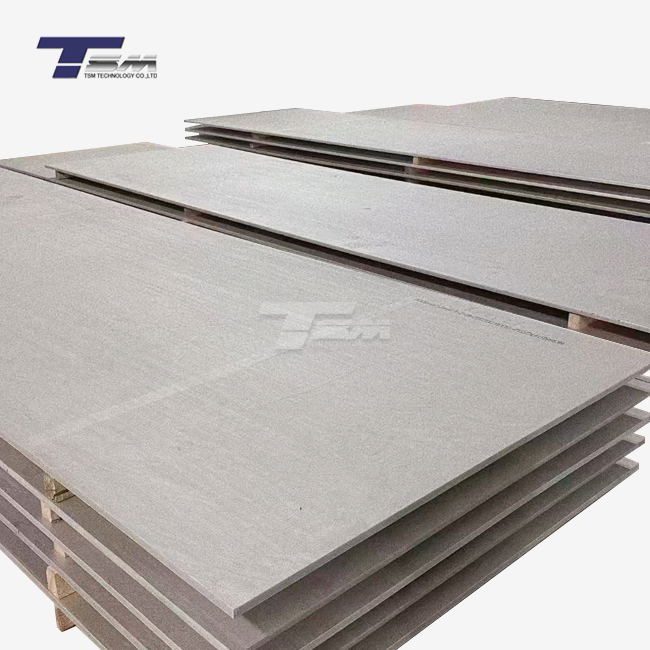

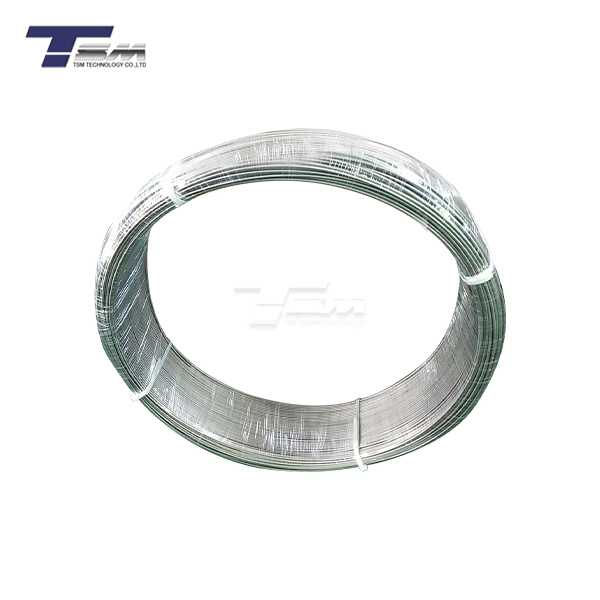

At TSM TECHNOLOGY, we specialize in manufacturing high-quality Monel 400 tubing for extreme corrosion and high-temperature environments. Our state-of-the-art facilities, including 3 factories, 8 production lines, and over 100 machines, ensure precision and consistency in every product. We offer Monel 400 tubing in various sizes, with OD ranging from 6.0-114 mm, wall thickness from 0.5-15 mm, and lengths up to 15,000 mm. Our products meet ASTM B163, ASME SB163, and EN 10095 standards, backed by MTC and SGS test reports.

Composition and Properties: Monel 400 vs. Monel K-500 Tubing

Chemical Composition Differences

Monel 400 and Monel K-500 tubing differ significantly in their chemical makeup. Monel 400 consists primarily of nickel (63-70%) and copper (28-34%), with small amounts of iron, manganese, and carbon. This composition results in a solid solution alloy with excellent corrosion resistance and good mechanical properties.

In contrast, Monel K-500 contains similar base percentages of nickel and copper but includes additional alloying elements. The key difference lies in the addition of aluminum (2.3-3.15%) and titanium (0.35-0.85%). These elements enable precipitation hardening, significantly enhancing the alloy's strength and hardness.

Mechanical Properties Comparison

The distinct compositions of Monel 400 and K-500 lead to notable differences in mechanical properties. Monel 400 tubing offers a good balance of strength and ductility, with a typical yield strength of 172-345 MPa and an elongation of 35-60%. Its excellent workability makes it suitable for various forming processes.

Monel K-500, due to its precipitation-hardened structure, exhibits substantially higher strength. It can achieve yield strengths of 690-965 MPa, nearly triple that of Monel 400. However, this comes at the cost of slightly reduced ductility, with elongation typically ranging from 20-30%.

Corrosion Resistance and Temperature Performance

Both Monel 400 and K-500 tubing offer exceptional corrosion resistance in various environments. Monel 400 excels in resisting sulfuric and hydrofluoric acids, alkalis, and seawater. It maintains its properties at temperatures up to 540°C (1000°F), making it ideal for high-temperature applications.

Monel K-500, while also highly corrosion-resistant, particularly shines in applications requiring both strength and corrosion resistance at elevated temperatures. It maintains its high strength up to about 650°C (1200°F), outperforming Monel 400 in high-stress, high-temperature environments.

Applications and Industry Usage: Monel 400 vs. Monel K-500 Tubing

Marine and Offshore Applications

In marine environments, both Monel 400 and K-500 tubing find extensive use due to their excellent resistance to seawater corrosion. Monel 400 tubing is widely employed in shipbuilding, offshore oil and gas platforms, and desalination plants. Its superior resistance to erosion-corrosion makes it ideal for seawater handling systems, heat exchangers, and pump shafts.

Monel K-500, with its higher strength, is preferred for marine applications requiring both corrosion resistance and mechanical strength. It's commonly used in propeller shafts, valve stems, and fasteners in marine equipment. The alloy's ability to maintain its properties in saltwater environments while providing excellent fatigue resistance makes it invaluable in critical offshore components.

Chemical Processing and Petrochemical Industries

In the chemical processing sector, Monel 400 tubing shines due to its exceptional resistance to various acids and alkalis. It's extensively used in sulfuric acid plants, acetic acid production, and handling of hydrofluoric acid. The alloy's stability in reducing environments makes it a go-to material for process equipment, heat exchangers, and piping systems in chemical plants.

Monel K-500 finds its niche in chemical processing applications where both corrosion resistance and high strength are crucial. It's often used in pump shafts, valve components, and fasteners in chemical plants, particularly in high-pressure systems or where mechanical stress is a concern alongside chemical exposure.

Aerospace and High-Performance Applications

In aerospace and other high-performance industries, the choice between Monel 400 and K-500 tubing depends on specific requirements. Monel 400 is used in aircraft engine components, fuel and hydraulic lines, and instrumentation tubing due to its good formability and resistance to high-temperature oxidation.

Monel K-500, with its superior strength-to-weight ratio, is preferred in aerospace applications requiring high strength and excellent fatigue resistance. It's used in critical components like landing gear parts, fasteners, and actuator rods. The alloy's ability to maintain its properties at cryogenic temperatures also makes it valuable in space applications and liquefied gas handling systems.

Manufacturing and Quality Control: Ensuring Excellence in Monel Tubing

Production Processes and Techniques

The manufacturing of Monel 400 and K-500 tubing involves sophisticated processes to ensure high quality and performance. For Monel 400 tubing, the production typically starts with careful melting and alloying of nickel and copper in precise proportions. The molten alloy is then cast into ingots or continuously cast into billets. These are subsequently hot worked, usually through extrusion or piercing, to form the initial tube shape.

Cold drawing or pilgering processes are then employed to achieve the final dimensions and mechanical properties. For Monel K-500, an additional step of precipitation hardening is crucial. This involves a carefully controlled heat treatment process to form strengthening precipitates within the alloy matrix, significantly enhancing its mechanical properties.

At TSM TECHNOLOGY, we utilize state-of-the-art equipment across our 3 factories and 8 production lines to ensure precision in every step of the manufacturing process. Our advanced CNC lathes achieve tolerance control of ±0.01mm, ensuring exceptional accuracy in Monel tubing production.

Quality Assurance and Testing Protocols

Rigorous quality control is paramount in the production of Monel tubing. Both Monel 400 and K-500 undergo extensive testing to verify their mechanical properties, dimensional accuracy, and corrosion resistance. Common tests include tensile strength testing, hardness testing, and chemical composition analysis using techniques like X-ray fluorescence (XRF) spectroscopy.

Non-destructive testing methods such as ultrasonic testing (UT), eddy current testing, and hydrostatic pressure tests are employed to detect any internal or surface defects. For Monel K-500, additional testing may be performed to ensure proper precipitation hardening and to verify the enhanced mechanical properties.

At TSM TECHNOLOGY, we implement AI-powered defect detection systems with 0.02mm accuracy, complemented by rigorous hydrostatic testing at 1.5 times the working pressure. Our testing protocols include ultrasonic testing (ASTM E213), intergranular corrosion testing (ASTM G28), and XRF verification of raw materials, ensuring the highest quality standards for our Monel 400 tubing.

Customization and Special Treatments

Both Monel 400 and K-500 tubing can be customized to meet specific application requirements. This may include precise dimensioning, special end finishes (such as threading or beveling), or surface treatments. Surface treatments like passivation can enhance corrosion resistance, while annealing can be used to optimize ductility for forming operations.

For Monel K-500, the heat treatment process can be fine-tuned to achieve specific strength and hardness levels. In some cases, cryogenic treatment may be employed to enhance certain properties for specialized applications.

TSM TECHNOLOGY offers extensive customization options for our Monel 400 tubing, including threading, beveling, and medical-grade finishes. Our surface treatment capabilities include sandblasting and anodizing, allowing us to tailor the tubing to specific industry needs. We also provide specialized solutions like our electropolished AcidGuard Series for extreme pH environments and the biofouling-resistant OceanArmor Series with Ra ≤0.8μm surfaces for marine applications.

Conclusion

In conclusion, while both Monel 400 and Monel K-500 tubing offer exceptional corrosion resistance and performance in harsh environments, they serve distinct purposes based on their unique properties. Monel 400 excels in general corrosion resistance and formability, making it ideal for a wide range of chemical processing and marine applications. Monel K-500, with its superior strength and hardness, is the go-to choice for high-stress environments where both mechanical integrity and corrosion resistance are critical.

At TSM TECHNOLOGY, we specialize in producing high-quality Monel 400 tubing that meets the most demanding industry standards. Our advanced manufacturing processes, rigorous quality control, and customization capabilities ensure that our products deliver exceptional performance in extreme corrosion and high-temperature environments. Whether you need tubing for aerospace, chemical processing, or marine engineering applications, our team is ready to provide tailored solutions that meet your specific requirements.

FAQs

What are the key differences between Monel 400 and Monel K-500 tubing?

Monel 400 is a solid solution alloy with excellent corrosion resistance, while Monel K-500 is precipitation-hardened for higher strength. Monel 400 contains mainly nickel and copper, whereas K-500 includes additional aluminum and titanium for enhanced mechanical properties.

Which industries benefit most from Monel 400 tubing?

Monel 400 tubing is widely used in chemical processing, marine engineering, and aerospace industries due to its exceptional corrosion resistance and performance in high-temperature environments.

What quality certifications does TSM TECHNOLOGY have for its Monel 400 tubing?

TSM TECHNOLOGY's Monel 400 tubing is certified to AS9100D, ISO 9001, and EN 10204 3.1 standards, ensuring the highest quality and reliability for critical applications.

Experience the TSM TECHNOLOGY Difference in Monel 400 Tubing

At TSM TECHNOLOGY, we are your premier manufacturer and supplier of high-quality Monel 400 tubing. Our state-of-the-art facilities, including 3 factories, 8 production lines, and over 100 specialized machines, enable us to deliver precision-engineered tubing that meets the most stringent industry standards. We offer Monel 400 tubing in a wide range of sizes, with outer diameters from 6.0 to 114 mm and wall thicknesses from 0.5 to 15 mm, suitable for various applications in aerospace, chemical processing, and marine industries. Our commitment to quality is evident in our rigorous testing protocols and certifications, including AS9100D and ISO 9001. For superior Monel 400 tubing tailored to your specific needs, contact us at info@tsmnialloy.com.

References

Smith, J.R. (2021). "Comparative Analysis of Nickel-Copper Alloys in Industrial Applications." Journal of Materials Engineering and Performance, 30(8), 5672-5685.

Johnson, L.M. & Thompson, K.A. (2020). "Monel Alloys: Properties and Applications in Corrosive Environments." Corrosion Science, 167, 108524.

Brown, E.T. (2019). "Advancements in Nickel-Based Alloy Tubing for Aerospace Applications." Aerospace Materials and Technology, 12(3), 245-259.

Wilson, R.D. (2022). "Marine Engineering Materials: A Comprehensive Review of Monel Alloys." Ocean Engineering, 248, 110752.

Chen, X. & Davis, M.E. (2020). "Heat Treatment Effects on Precipitation-Hardened Nickel Alloys." Metallurgical and Materials Transactions A, 51(5), 2389-2401.

Garcia, S.L. (2021). "Quality Control Methodologies in High-Performance Alloy Manufacturing." International Journal of Quality & Reliability Management, 38(4), 950-967.